A kind of tooling for nickel base alloy pipe welding

A nickel-based alloy and pipeline technology, which is applied in the field of welding tooling for nickel-based alloy pipelines, can solve the problems of poor welding quality of nickel-based alloy pipelines, large linear expansion coefficient of nickel materials, and failure to meet design requirements, etc., to improve welding quality, The effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

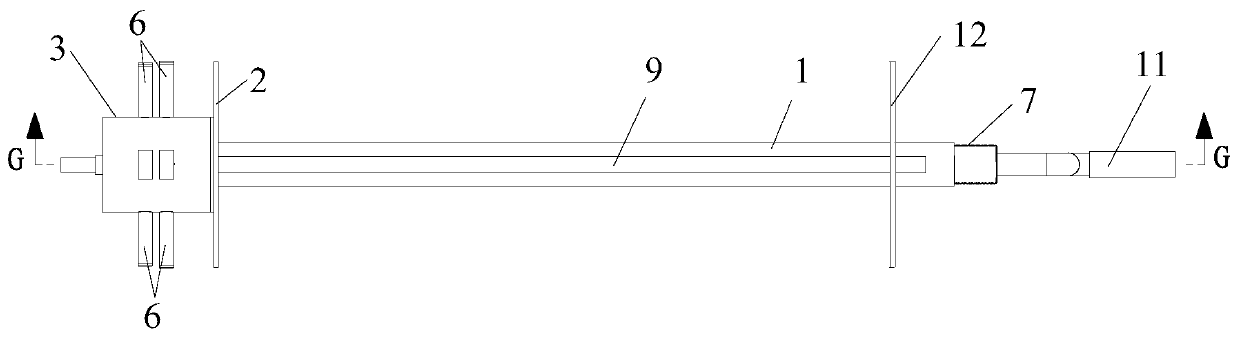

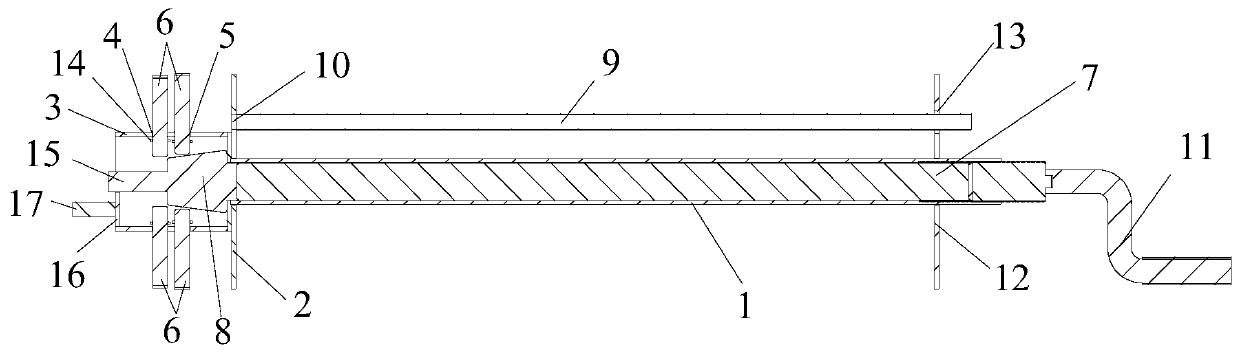

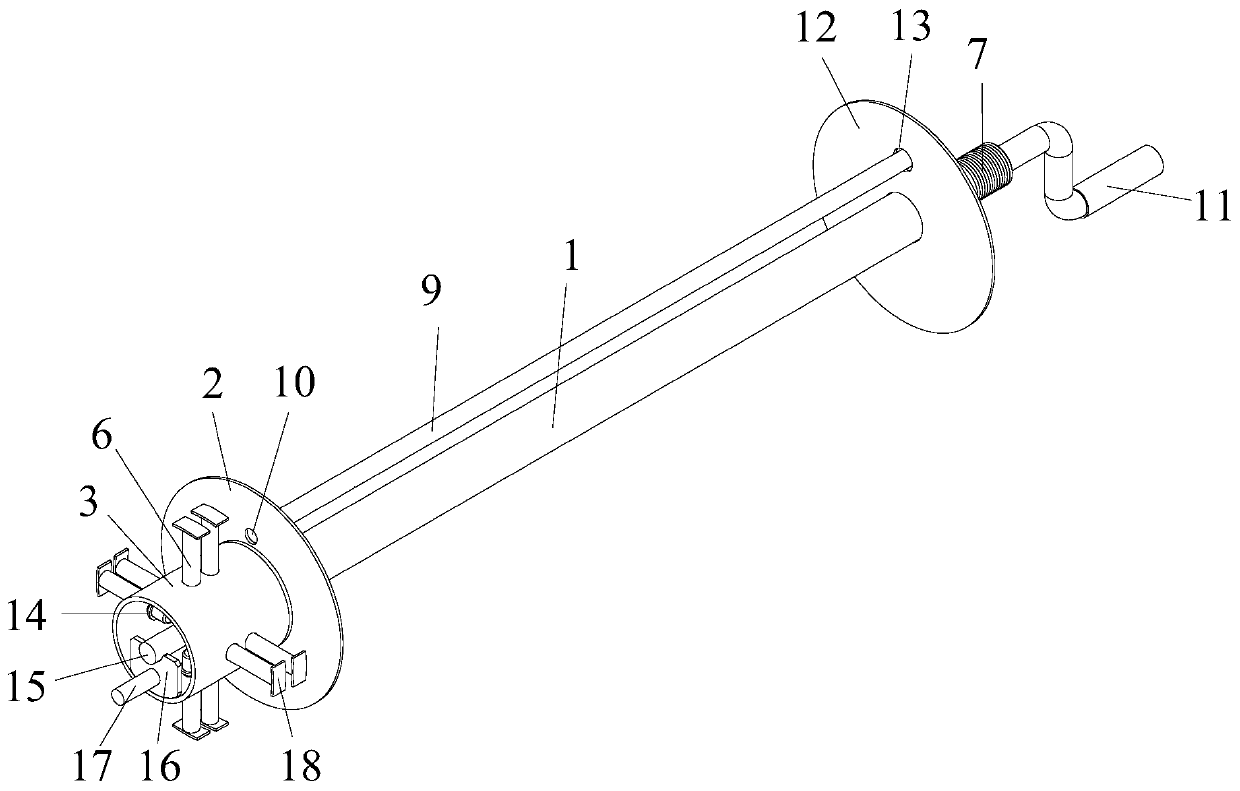

[0022] Such as figure 1 , figure 2 and image 3 As shown, a nickel-based alloy pipe welding tooling includes a first sleeve 1, the end of the first sleeve 1 is fixed with a baffle plate 2 for blocking argon, and the baffle plate 2 is connected with a second sleeve 3. The cylinder wall of the second sleeve 3 is provided with a first positioning hole 4 and a second positioning hole 5, and the first positioning hole 4 and the second positioning hole 5 can be slidably sleeved with a push rod 6, The first sleeve 1 is connected with a push rod 7, the first sleeve 1 and the push rod 7 are threaded together, the end of the push rod 7 is welded with a truncated cone 8, and the truncated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com