A kind of nano-palladium-silver alloy catalytic material for catalytic reduction of nitrate in water and its preparation method and application

A catalytic material, palladium-silver alloy technology, applied in chemical instruments and methods, reduced water/sewage treatment, nanotechnology for materials and surface science, etc., can solve the problem that nitrate has not been eliminated and is difficult to be widely used and treated Low efficiency and other problems, to achieve the effect of easy operation, easy industrial production, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

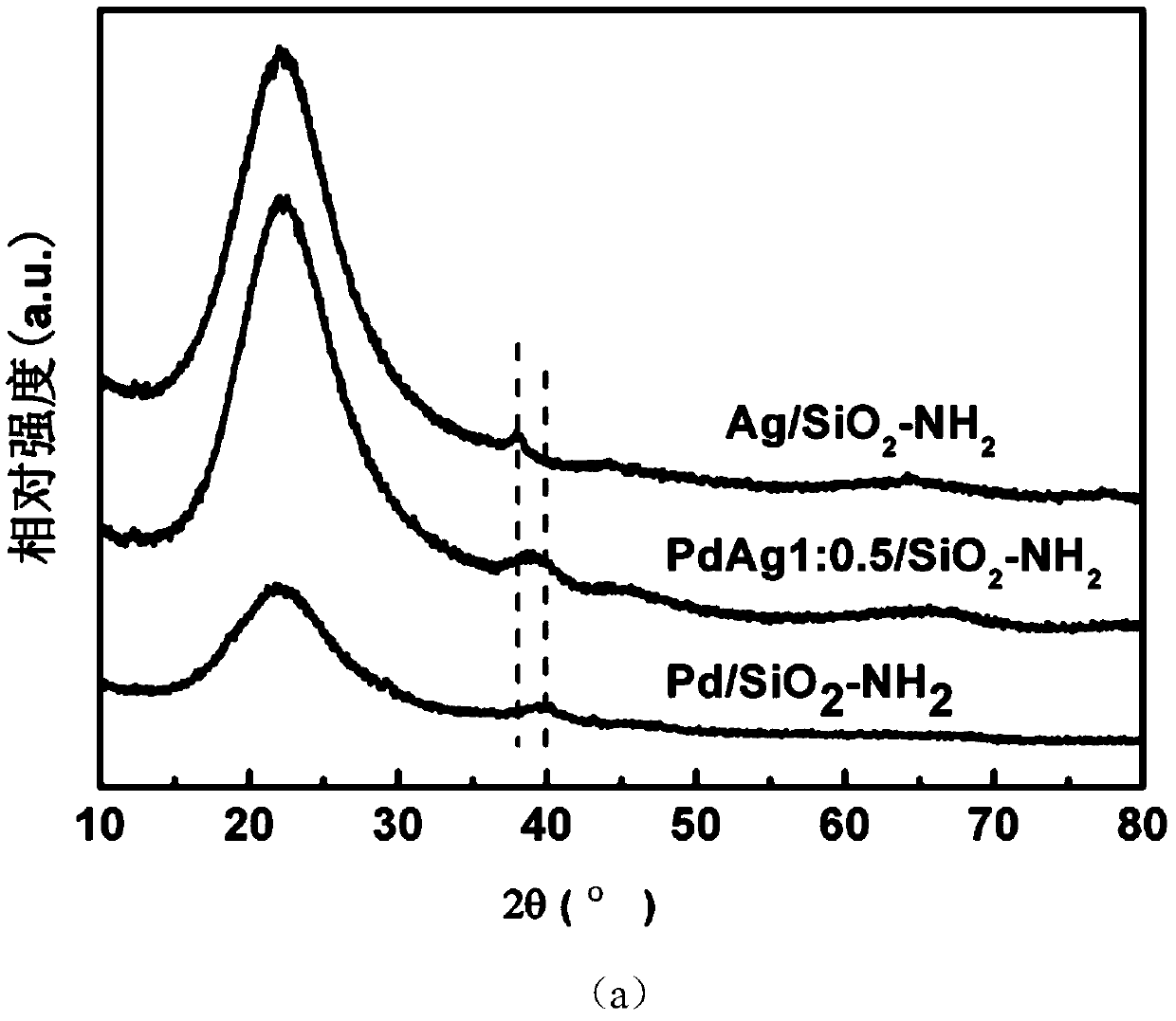

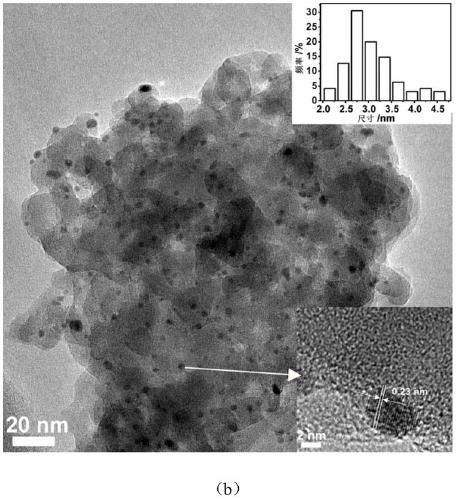

[0043] Add 10 grams of dry silicon oxide to 400 milliliters of absolute ethanol, stir for 0.5 hours, add 1 milliliter of 3-aminopropyltriethoxysilane, put it in a 70 ° C water bath, stir for 24 hours by reflux, and then wash , and dried in vacuum at 40°C for 12 hours to obtain amino-modified silica. Add 0.22 g of sodium chloride and 0.167 g of palladium chloride into 40 ml of deionized water, and sonicate for 10 minutes, at which time the palladium chloride is completely dissolved to obtain a sodium chloride solution of palladium chloride. Take a beaker, add 500 ml of deionized water, add the prepared amino-modified silicon oxide, after stirring evenly, add the sodium chloride solution of palladium chloride, saturated adsorption at room temperature for 1 hour, then add 40 ml of dissolved 2 grams of fresh solution of potassium borohydride, continue to stir for 0.5 hours, rinse 3-5 times with 50 milliliters of deionized water, and dry in a vacuum oven at 40°C for 12 hours.

[0...

Embodiment 2

[0046] Add 1 kg of dry silicon oxide to 40 liters of absolute ethanol, stir for 0.5 hours, add 100 ml of 3-aminopropyltriethoxysilane, put it in a 70°C water bath, stir for 24 hours by reflux, and then wash , and dried in vacuum at 40°C for 12 hours to obtain amino-modified silica. 22 grams of sodium chloride and 16.7 grams of palladium chloride were added to 4 liters of deionized water, and ultrasonication was performed for 10 minutes. At this time, the palladium chloride was completely dissolved to obtain a sodium chloride solution of palladium chloride. Take a beaker, add 50 liters of deionized water, add amino-modified silicon oxide, stir evenly, add the sodium chloride solution of palladium chloride, saturated adsorption at room temperature for 1 hour, then add 4 liters of dissolved 200 grams The fresh solution of potassium borohydride was continuously stirred for 0.5 hours, washed 3-5 times with 5 liters of deionized water, and dried in a vacuum oven at 40°C for 12 hours...

Embodiment 3

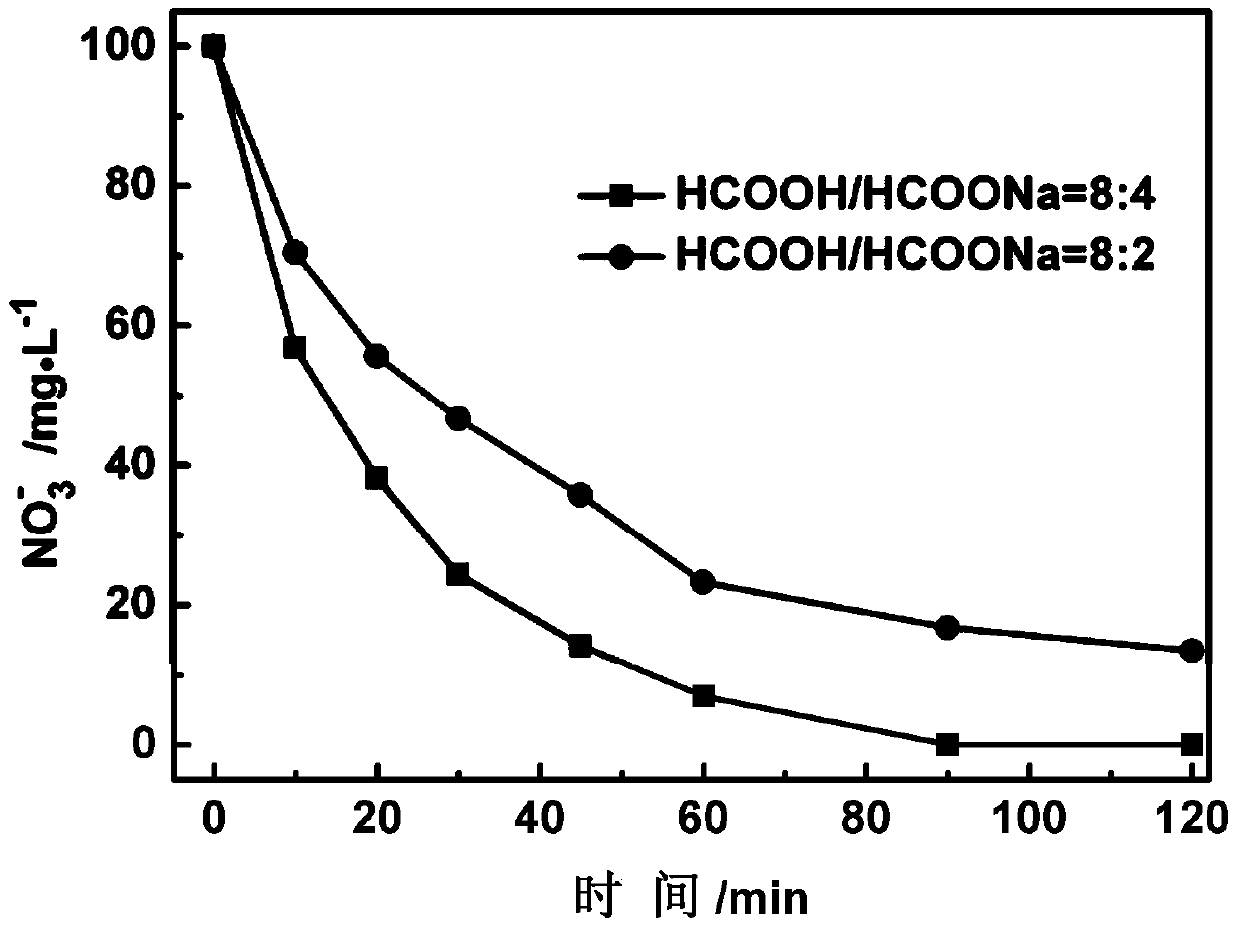

[0049] Add 178 milliliters of deionized water in the 200 milliliter flask, get the PdAg / SiO that 0.4 gram embodiment 1 prepares 2 -NH 2 Catalyst, ultrasonically dispersed for 5 minutes, passed nitrogen for 15 minutes to remove dissolved oxygen in water, then added 20 ml of nitrate and 2 ml of formic acid / sodium formate solution, tightly stoppered, and stirred under closed conditions. figure 2 It shows the results of nitrate reduction catalyzed by the catalyst under different formic acid and sodium formate concentrations.

[0050] a. When the concentration of nitrate in water is 100 mg / liter, and the concentration ratio of formic acid / sodium formate is 8 / 2 mmol / liter, the concentration of nitrate in water after 1 hour of reaction is 23 mg / liter.

[0051] b. When the concentration of nitrate in water is 100 mg / liter, and the concentration ratio of formic acid / sodium formate is 8 / 4 mmol / liter, the concentration of nitrate in water after 1 hour of reaction is 7 mg / liter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com