Method for preparing electrode materials for lithium ion batteries by defect control method

A lithium-ion battery and electrode material technology, which is applied in the field of lithium-ion battery electrode materials prepared by defect control method, can solve the problems of inability to obtain high-performance lithium-ion battery materials, and achieve low production cost, simple process route, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

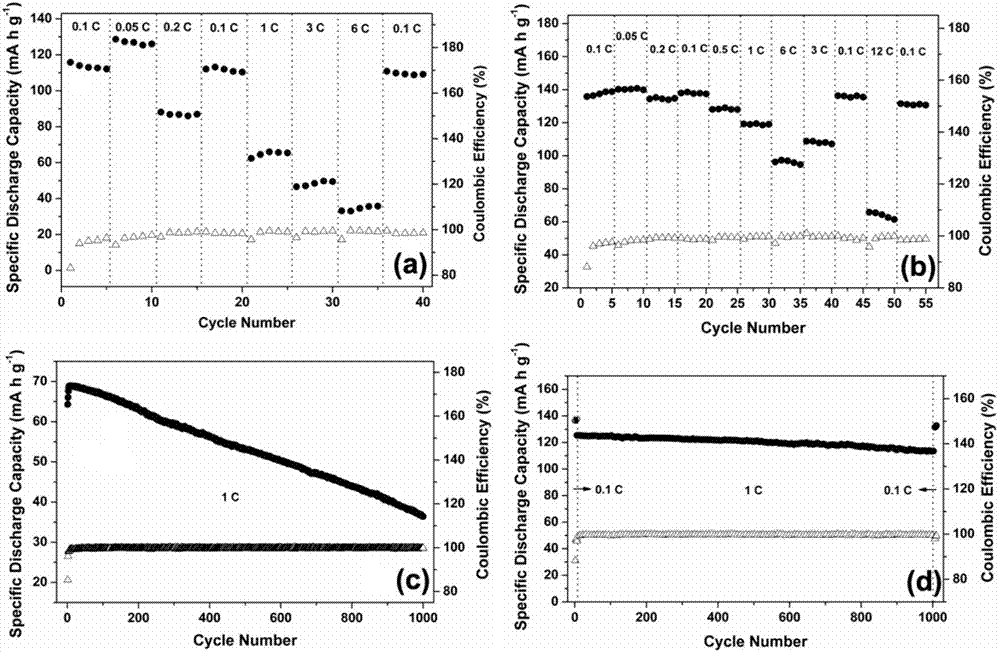

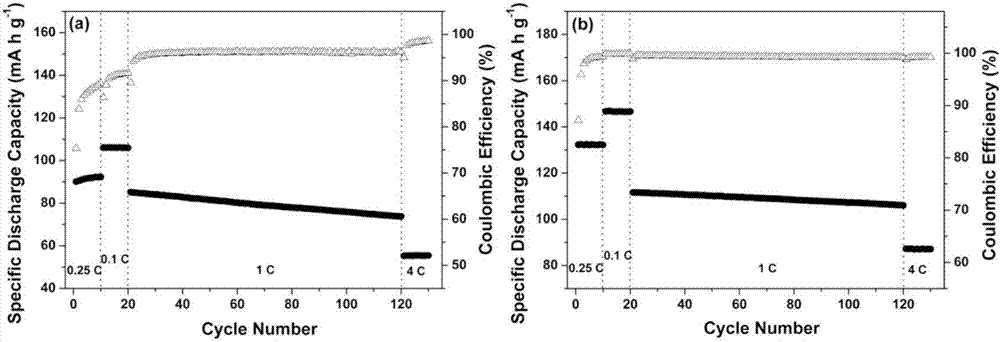

Image

Examples

Embodiment 1

[0038] 1. Vanadium phosphate (VPO 4 ) During the preparation of the precursor, the V with certain defects is pre-formed 0.8 PO 4 ,; the vanadium source (V 2 o 5 ), phosphorus source (NH 4 h 2 PO 4 ) and reducing agent (carbon black) according to V x PO 4 Preparation of vanadium phosphate precursor by stoichiometric ratio, pre-forming intermediate V with certain defects 0.8 PO 4 ;

[0039] Solid-phase sintering method: Pretreat the vanadium source, phosphorus source and reducing agent according to the stoichiometric ratio (the reducing agent is in excess of 20%) under the protection of argon or nitrogen at 300°C for 4 hours to release NH 3 、H 2 O, etc., and then calcined at 500°C for 20h under the protection of argon or nitrogen, the intermediate with certain defects formed in advance can be synthesized.

[0040] 2. Will pre-form a certain defect V 0.8 PO 4 All or part of the defects are repaired to prepare a high-performance lithium vanadium phosphate material. ...

Embodiment 2

[0043] 1. Vanadium phosphate (VPO 4 ) During the preparation of the precursor, the V with certain defects is pre-formed 0.85 PO 4 ; The vanadium source (V 2 o 3 ), phosphorus source ((NH 4 ) 2 HPO 4 ) and reducing agent (sucrose) according to V 085 PO 4 Preparation of vanadium phosphate precursor by stoichiometric ratio, pre-forming intermediate V with certain defects 085 PO 4 ;

[0044] Hydrothermal reaction method: React the vanadium source, phosphorus source and reducing agent in an aqueous solution at 100°C for 30 hours according to the stoichiometric ratio (the reducing agent is in excess of 15%), wash the reaction product with water, and place it under the protection of argon or nitrogen Calcined at 500°C for 10 hours, the intermediate V with certain defects formed in advance can be synthesized 085 PO 4 .

[0045] 2. Will pre-form a certain defect V 0.8 PO 4 Perform all or part of the defect repair to prepare high-performance lithium vanadium phosphate (Li...

Embodiment 3

[0048] 1. Vanadium phosphate (VPO 4 ) During the preparation of the precursor, the V with certain defects is pre-formed 0.9 PO 4 ; The vanadium source (VO 2 ), phosphorus source (H 3 PO 4 ) and reducing agent (citric acid) according to V x PO 4 Preparation of vanadium phosphate precursor by stoichiometric ratio, pre-forming intermediate V with certain defects 0.9 PO 4 ;

[0049] Solvothermal reaction method: react the vanadium source, phosphorus source and reducing agent in an ethylene glycol solution at 120-240°C for 4-30 hours according to the stoichiometric ratio (where the reducing agent is in excess of 50%), and wash the reaction product in water Under the protection of argon or nitrogen, calcining at 500-720°C for 3-10h, the intermediate V with certain defects formed in advance can be synthesized. 0.9 PO 4 .

[0050] 2. Will pre-form a certain defect V 0.9 PO 4 Perform all or part of the defect repair to prepare high-performance lithium vanadium phosphate (L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com