SCRF system capable of actively controlling catalytic environment

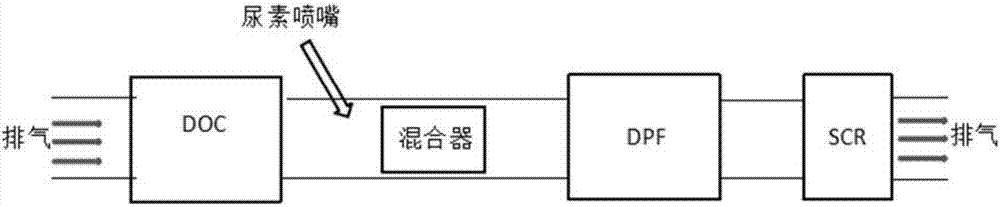

An active control and environmental technology, applied in the field of SCRF system, can solve the problems of low NOx conversion efficiency, large volume, unfavorable installation layout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

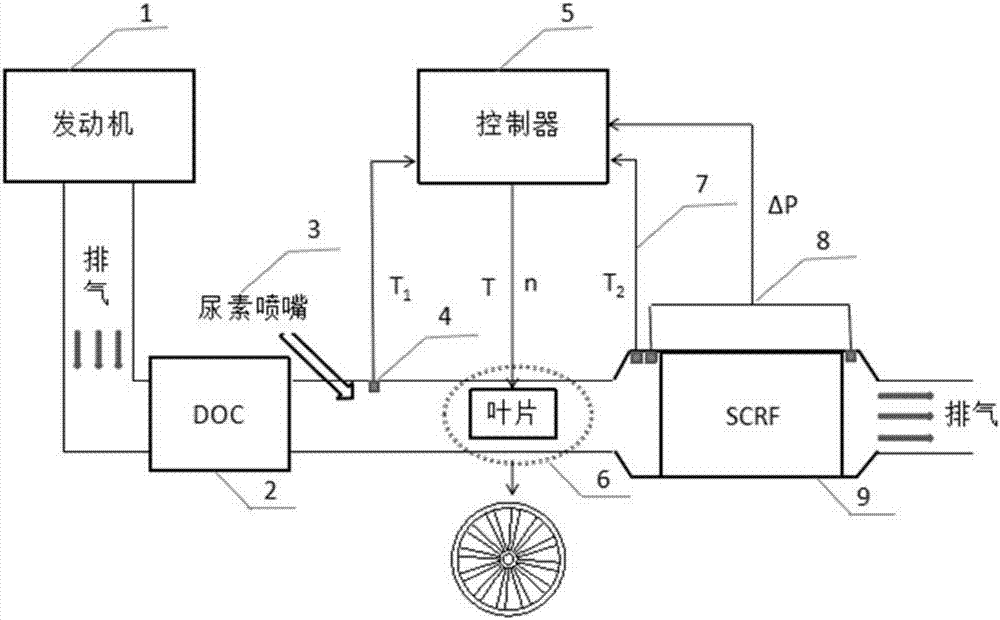

[0022] see figure 2 , a kind of SCRF system that actively controls catalytic environment described in a preferred embodiment of the present invention, comprises DOC catalyst (2), urea injection device, blade (6), controller, SCRF (that is to have SCR coating DPF) (9). DOC catalyst for oxidation of NO to NO 2 , improve the conversion efficiency of SCRF to NOx; oxidize HC and CO at the same time, increase the exhaust temperature, which is beneficial to realize SCRF regeneration; urea injection device is used to inject urea into the exhaust pipe; It is used to heat the urea sprayed by the urea injection device to avoid crystallization of urea and make NH 3 It is fully mixed with the exhaust gas; the controller determines the heating temperature and speed of the blades according to the exhaust temperature in the exhaust pipe of the diesel engine and the gas temperature and pressure difference in the SCRF system, and actively controls the catalytic environment of the SCRF system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com