Treatment method for dirt on surface of electroplated chromium product

A treatment method and chrome electroplating technology are applied in the field of treatment of surface contamination of chrome electroplating products, which can solve problems such as increased production cost, product contamination, loss of money, etc., to ensure cleanliness, improve drug spot contamination, and reduce huge effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

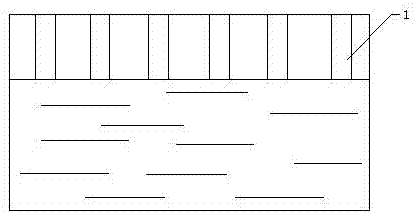

[0022] Choose the Great Wall door trim, after degreasing, roughening, recycling, two reductions, palladium activation, degumming, chemical nickel plating, pre-copper plating, copper plating, acid activation, semi-bright nickel plating, bright nickel plating, nickel seal , chrome plating, reduction and drying processes, in which the previous process is washed into the next process by water. In the reduction process and the water washing process after the reduction process, such as figure 1 As shown, reduce the liquid level of the reduction tank and the washing tank after the reduction process, so that the liquid level is located at the bottom of the rib plate 1 on both sides of each tank, so as to ensure that the electroplating conductive plate of the electroplating rack is not in contact with each liquid level.

[0023] After the reduction process, add two spraying and washing processes, and the spraying and washing process uses a spraying and washing pool, such as figure 2 ...

Embodiment 2

[0026] Choose the Great Wall door trim, after degreasing, roughening, recycling, two reductions, palladium activation, degumming, chemical nickel plating, pre-copper plating, copper plating, acid activation, semi-bright nickel plating, bright nickel plating, nickel seal , chrome plating, reduction and drying processes, in which the previous process is washed into the next process by water. In the reduction process and the water washing process after the reduction process, such as figure 1 As shown, reduce the liquid level of the reduction tank and the washing tank after the reduction process, so that the liquid level is located at the bottom of the rib plate 1 on both sides of each tank, so as to ensure that the electroplating conductive plate of the electroplating rack is not in contact with each liquid level.

[0027] After the reduction process, add two spraying and washing processes, and the spraying and washing process uses a spraying and washing pool, such as figure 2 ...

Embodiment 3

[0030] Choose the Great Wall door trim, after degreasing, roughening, recycling, two reductions, palladium activation, degumming, chemical nickel plating, pre-copper plating, copper plating, acid activation, semi-bright nickel plating, bright nickel plating, nickel seal , chrome plating, reduction and drying processes, in which the previous process is washed into the next process by water. In the reduction process and the water washing process after the reduction process, such as figure 1 As shown, reduce the liquid level of the reduction tank and the washing tank after the reduction process, so that the liquid level is located at the bottom of the rib plate 1 on both sides of each tank, so as to ensure that the electroplating conductive plate of the electroplating hanger is not in contact with each liquid level.

[0031] After the reduction process, add two spraying and washing processes, and the spraying and washing process uses a spraying and washing pool, such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com