Modular manufacturing multi-purpose winding-type vacuum coating machine

A vacuum coating machine, multi-purpose technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of limited film production, high dust pollution, poor atmosphere isolation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

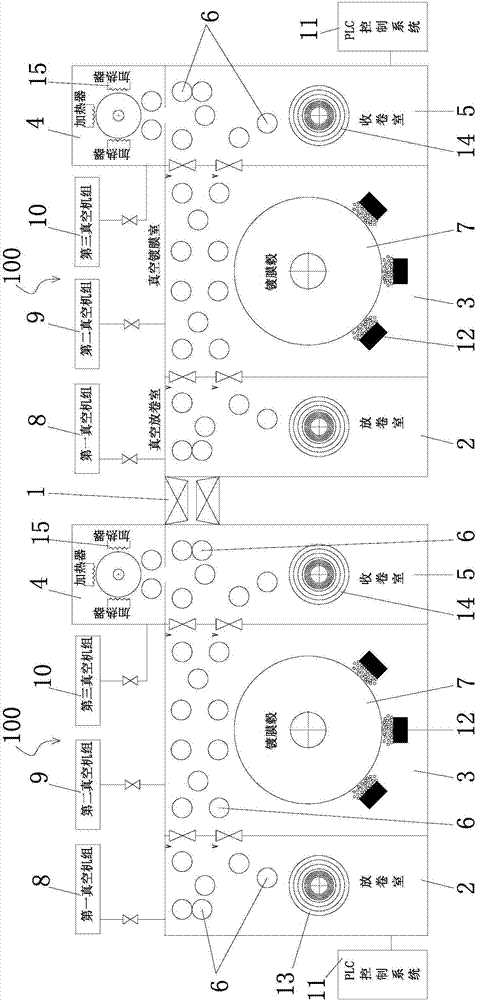

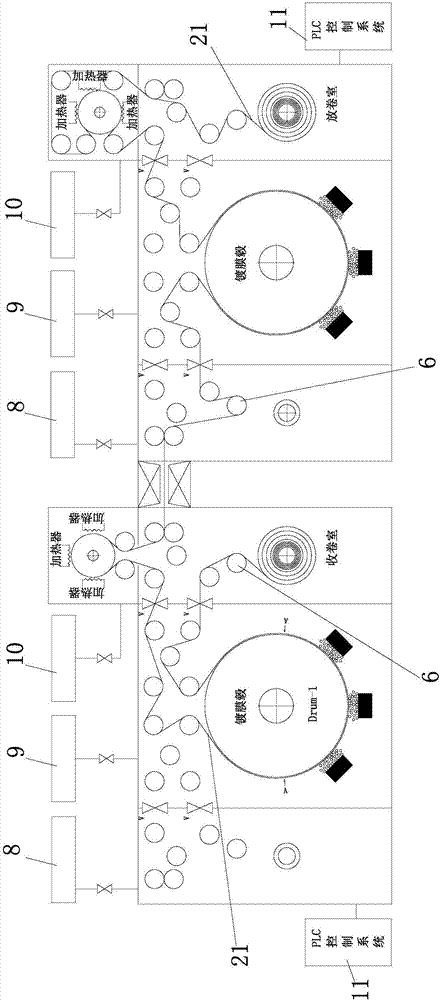

[0033] Embodiment 1, reference Figure 1 to Figure 3 As shown, a modular manufacturing multi-purpose roll-to-roll vacuum coating machine includes two vacuum roll-to-roll coating system units 100, the two vacuum roll-to-roll coating system units 100 are connected by a vacuum coupling valve 1, and the roll to be coated The material 21 passes through the vacuum connection valve 1 and enters the next empty winding coating system unit 100; the vacuum winding coating system unit 100 includes an unwinding chamber 2, a coating chamber 3, a heat treatment chamber 4 and a winding chamber 5, all of which are There are several spools 6 that can be used for tensioning, conveying the coil material to be coated, and changing the winding direction of the coil material to be coated. The coating chamber 3 is provided with a coating hub 7. After coating one side in the roll-to-roll coating system unit, the other side is coated in the next vacuum roll-to-roll coating system unit because the reel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com