Preparation device and preparation method of graphene base bar

A technology for preparing devices and olefin-based rods, which is applied in the field of preparation devices for new graphene-based rods, can solve the problems of few researches on graphene-based micro-rods, achieve wide application prospects and application value, reduce heat loss, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

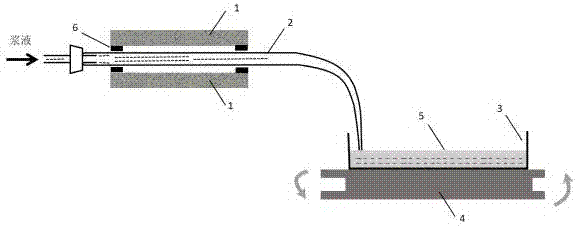

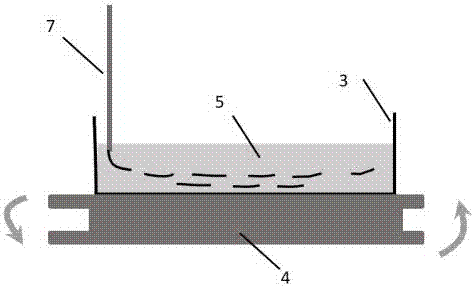

[0013] Specific implementation mode one: as figure 1 As shown, the graphene-based rod preparation device of this embodiment is mainly composed of a constant temperature heating device 1, a silica capillary column 2, a solution tank 3, a rotating table 4, a receiving liquid 5 and a thermal insulation plug.

[0014] The 6 mg / ml graphene oxide slurry (solvent is water) synthesized by the existing method is injected into the silica capillary column 2 at a speed of 1ml / min through an external peristaltic pump, and the slurry enters the constant temperature heating through the silica capillary column 2 Heat treatment is carried out in device 1, graphene oxide hydrothermal reduction undergoes decarboxylation reaction, further reduces the spacing, and becomes preliminary wet reducing graphene oxide fibers under the action of ππ conjugation, and preliminary wet reducing oxidation under the thrust of an external peristaltic pump The graphene fiber is further injected into the rotating s...

specific Embodiment approach 2

[0016] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the slurry uses graphene oxide / polyvinyl alcohol blend aqueous solution (the mass ratio of the two is 1:1), and the total concentration is 5 mg / ml.

specific Embodiment approach 3

[0017] Specific embodiment 3: The difference between this embodiment and specific embodiments 1 and 2 is that the pure graphene oxide slurry is replaced by graphene oxide / lithium iron phosphate aqueous solution (the mass ratio of the two is 1:2), and the total concentration is 4 mg / ml.

[0018] Specific implementation method four: this embodiment is different from specific implementation modes one, two, and three in that the constant temperature heating device 1 is a high-temperature oven, and the high-temperature oven is an oven after self-processing, that is, the silica capillary column 2 can be stretched into and connected. Out, the temperature range can be adjusted from 0-500 ℃, here is set to 400 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com