Gas supply small valve protection device of pneumatic valve

A technology for valve protection and pneumatic valves, applied to valve devices, valve operating/release devices, cocks including cut-off devices, etc., can solve the problems of high material consumption, poor isolation effect, and no suitable chain for binding straps, etc., to achieve Effect of avoiding economic loss, wide application prospect and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A small air supply valve protection device for a pneumatic valve according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

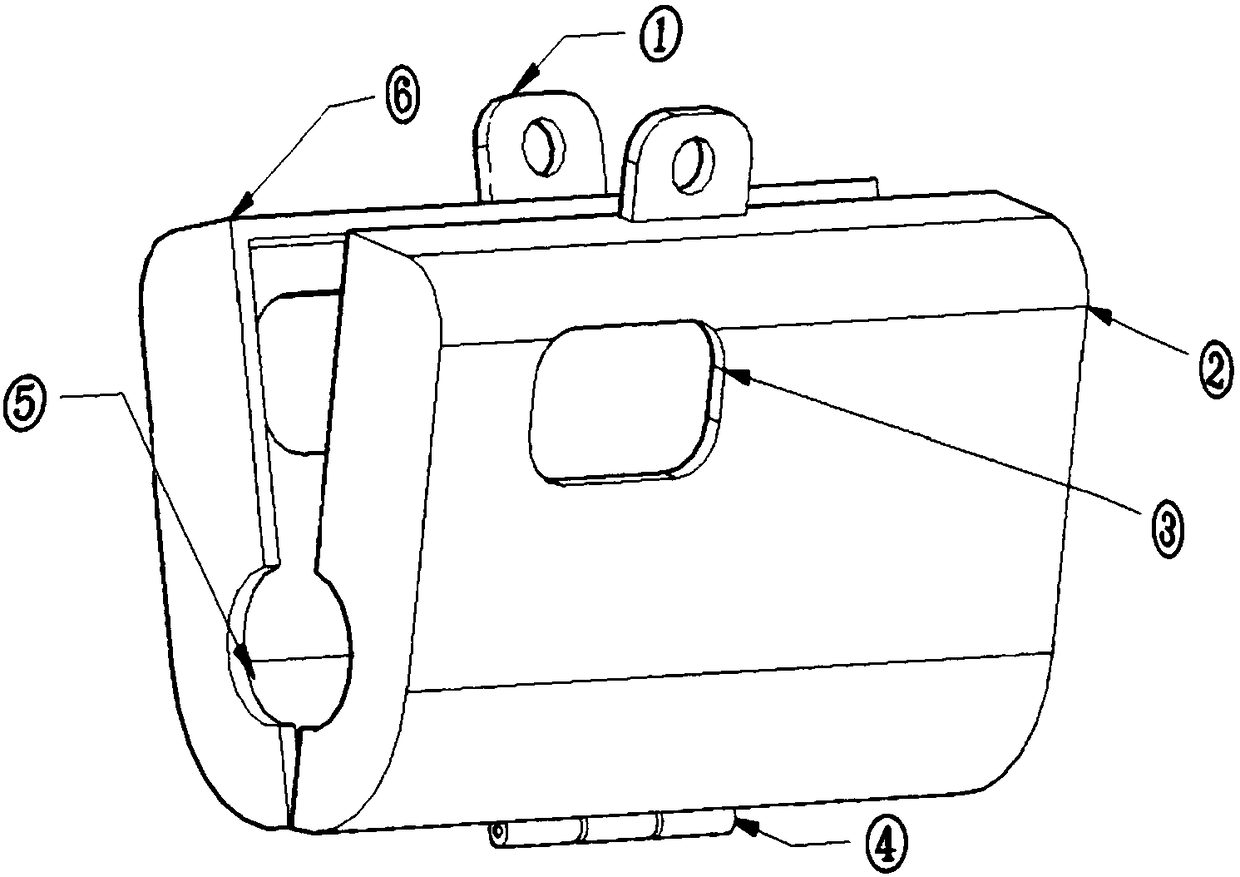

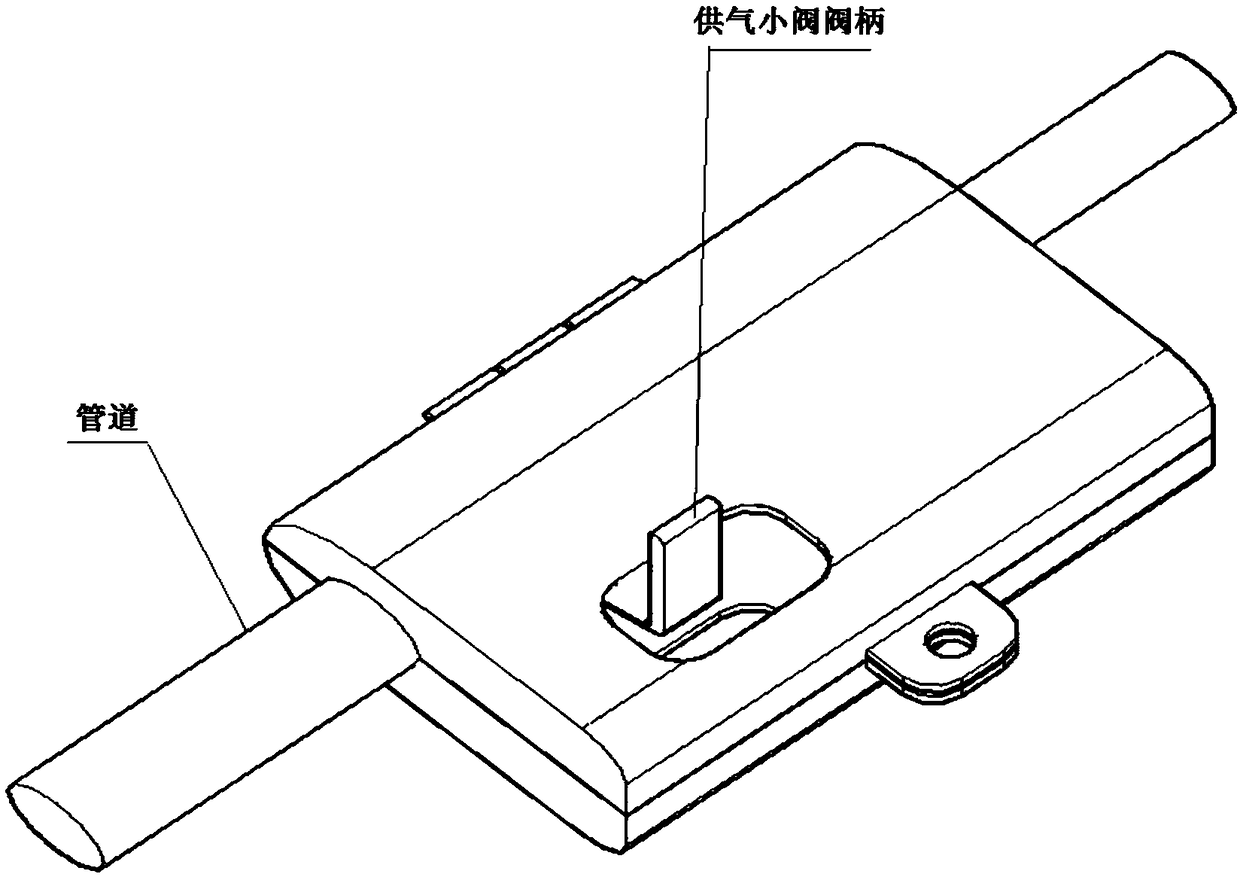

[0019] Such as figure 1 with figure 2 As shown, a small air supply valve protection device for a pneumatic valve includes half body A2 and half body B6, the lower ends of half body A2 and half body B6 are connected by lock hinge 4; the upper ends of half body A2 and half body B6 A lock hole 1 is respectively provided at the same position for locking; a pipe hole 5 is respectively provided at the same position on the left and right sides of the half body A2 and the half body B6, and when the half body A2 and the half body B6 are closed, the pipe Hole 5 fits with the pipeline of the small air supply valve; valve handle hole 3 is respectively provided at the same position on the front and rear sides of half body A2 and half body B6, and the valve handle for t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com