Needle type vacuum pumping and heat seal coding device used for pure electric shaping packaging machine

A plastic packaging and vacuuming technology, which is applied in the fields of tea packaging, needle vacuuming and heat sealing and coding devices, can solve the problems of incomplete air extraction, high maintenance cost, unstable operation, etc., and achieve complete vacuuming effect. , Low maintenance cost, complete vacuuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention takes the factory building of Xing'an Metal Co., Ltd., Anxi County, Fujian Province as the specific implementation location, and provides the following specific examples.

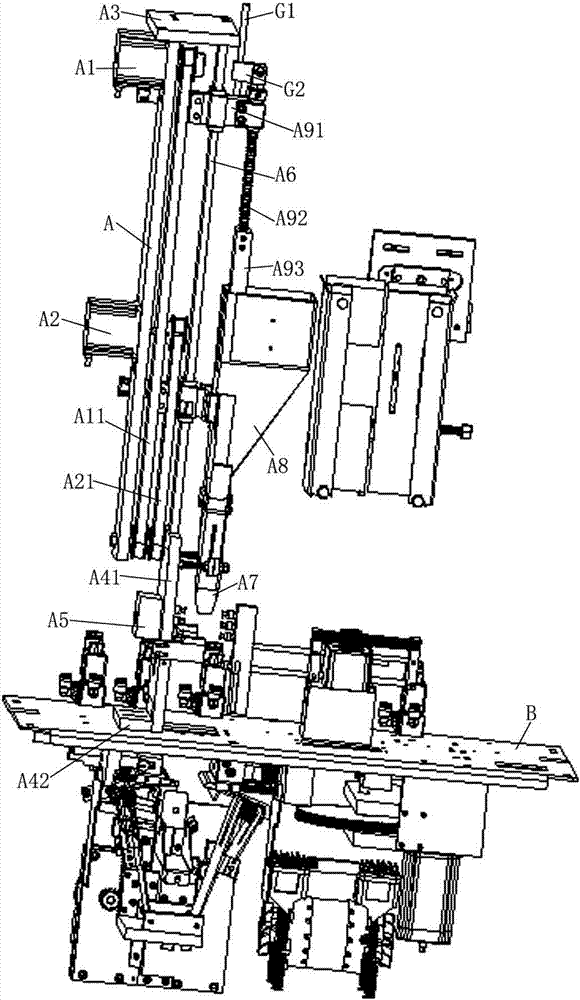

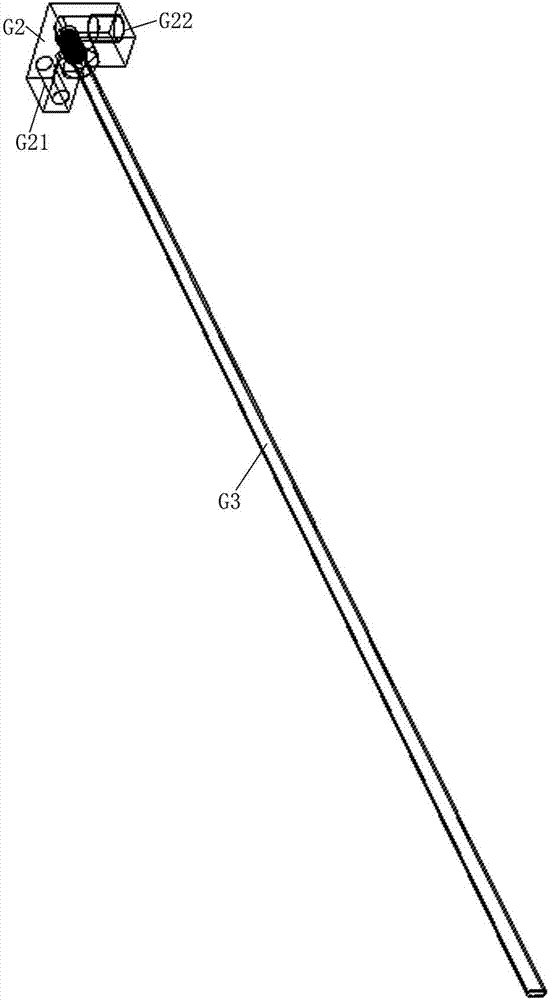

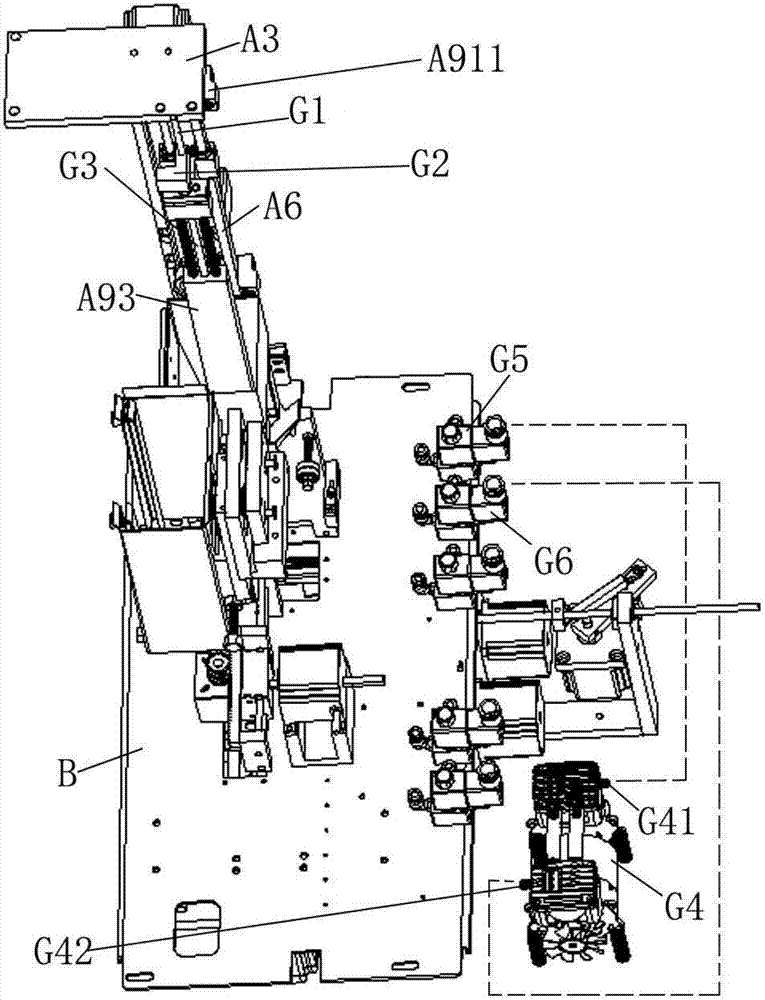

[0087] Such as figure 1 , image 3 , Figure 4 As shown, the needle-type vacuuming and heat-sealing coding device for pure electric plastic packaging machines is composed of a needle-suction bag vacuum system, a needle-type tea foam blowing system, and a bag sealing coding system. characterized in that,

[0088] The needle-suction bag vacuum system is used as the upper station of the bag sealing coding system. After the vacuuming operation of the needle-suction bag vacuum system is completed, the needle-type tea foam blowing system completes the tea foam blowing operation. The foaming operation can be carried out simultaneously or sequentially with the sealing and coding operations of the bag sealing coding system. The vacuuming operation and the tea foaming operation share t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com