Automatic production method and system of sour pulped rice noodles

A Physalis rice noodle and production system technology, which is applied in food forming, food science, application, etc., can solve the problems of high difficulty in controlling quality, food hygiene and safety requirements, high manual participation procedures and complex processes, etc. , to achieve the effect of avoiding errors, easy control and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The automatic production method of Physalis Rice Noodles described in this embodiment is prepared according to the following steps:

[0035] ① Cleaning of raw materials: Wash the rice with clean water, drain the sewage, soak the rice in clean water accounting for 40-50% of the weight of the rice for 2-5 hours, until the rice grains are white and easy to crush;

[0036] ② Refining: Refining the processed rice with a refiner, no additional water is required for refining;

[0037] ③Preliminary fermentation: Put the ground rice milk into the filter bag and squeeze it, squeeze out the water to ensure that the water content is between 30-35%, and the extrusion time is 0.5-1 hour. The space temperature of the bag is raised by 10-15°C, so that the rice milk undergoes preliminary and low-level fermentation to obtain block rice noodles;

[0038] ④Secondary fermentation: send the extruded rice noodles into a mixer, and add the pre-fermented and acidified rice noodles at a ratio o...

Embodiment 2

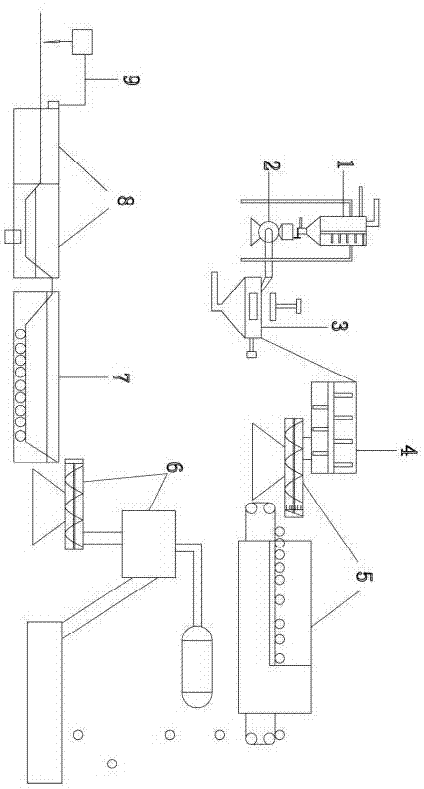

[0045] Such as figure 1 As shown, the automatic production system of Physalis Rice Noodles described in this embodiment includes a raw material cleaning and soaking mechanism 1, a refining mechanism 2, an extrusion primary fermentation mechanism 3, a stirring secondary fermentation mechanism 4, a primary aging mechanism 5, and a pressing and forming mechanism. Mechanism 6, secondary curing mechanism 7, cooling and rinsing mechanism 8, cutting mechanism 9, each mechanism is set up in sequence;

[0046] The raw material cleaning and soaking mechanism 1 includes a rice washing tank, a rice tank bracket, a feeding pipe, a water inlet pipe, a drain pipe, a spiral mixer, a feeding drain pipe, and an automatic valve; the feeding pipe, the water inlet pipe, the drain pipe, the spiral The agitator, the draining pipe and the automatic valve are all installed on the rice washing tank, and the rice washing tank is installed on the rice tank support, wherein the feeding pipe and the water ...

Embodiment 3

[0056] Such as figure 1 As shown, the automatic production system of Physalis noodle described in this embodiment described in this embodiment is basically the same as in Embodiment 2, the difference is that: the heating device adopts high-temperature steam; After softening, it enters the boiling channel; a drain is set under the rinsing tank. After the rice noodles are rinsed for a period of time, the water and impurities in the tank are discharged, and new water is added to keep it clean.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com