High-seal seamless hot-melt sleeve and its production method and application method

A seamless thermal and high-sealing technology, applied in the direction of pipes/pipe joints/fittings, pipe connection layout, damage protection, etc., can solve problems such as gaps at lap joints, insufficient thermal fusion of longitudinal seams, and insufficient welding , to achieve the effect of reducing the incidence of pipeline accidents, tight hot-melt connection and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

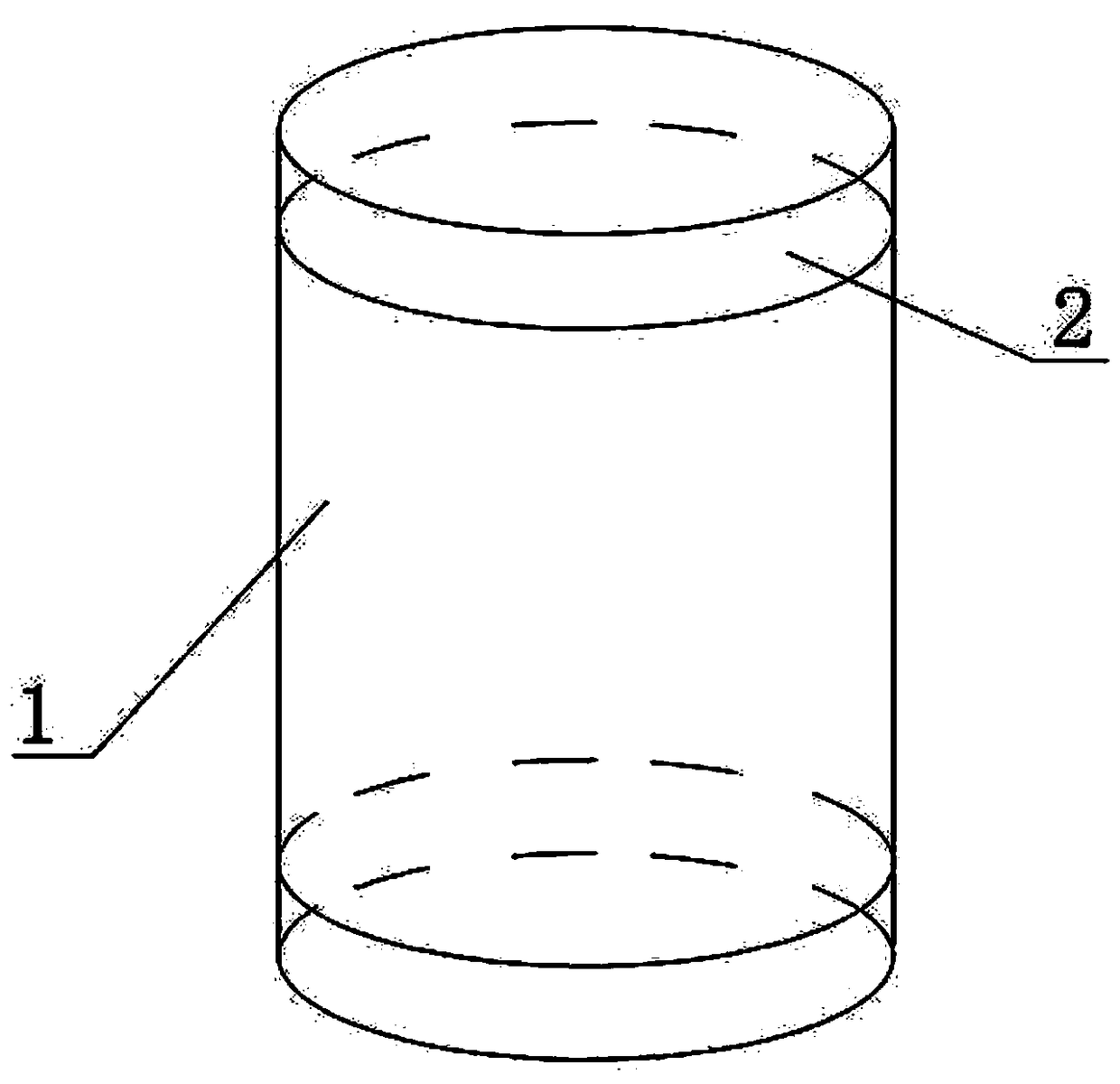

[0028] Such as figure 1 As shown, the high-seal seamless hot-melt sleeve of the present invention includes: a PE short pipe 1 and an electric heat-melt net 2, the electric heat-melt net 2 is embedded on the inner walls of the two ports of the PE short pipe 1 by extrusion, The length of the net 2 embedded in the PE short pipe 1 from the edge of the port is 30-300mm. The method of embedding the electrothermal fusion net is the extrusion embedding method. The material of the electrothermal fusion net is composed of nickel alloy resistance wire. The force used for extrusion is related to the specification of the PE short pipe 1. The inner diameter (DN) of the PE short pipe 1: 100 ≤DN4 -2×10 4 N, 500≤DN4 -5×10 4 N, 1000≤DN4 -10 5 N (DN is the nominal inner diameter in mm).

Embodiment 2

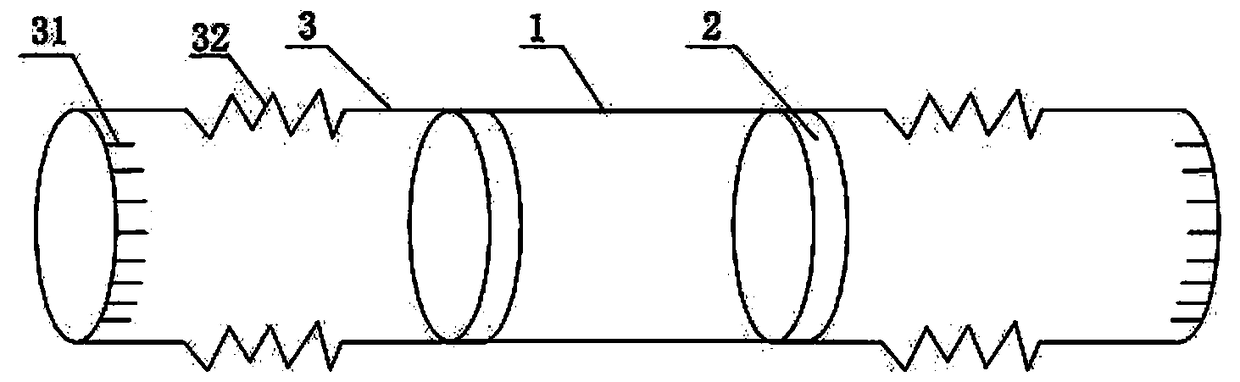

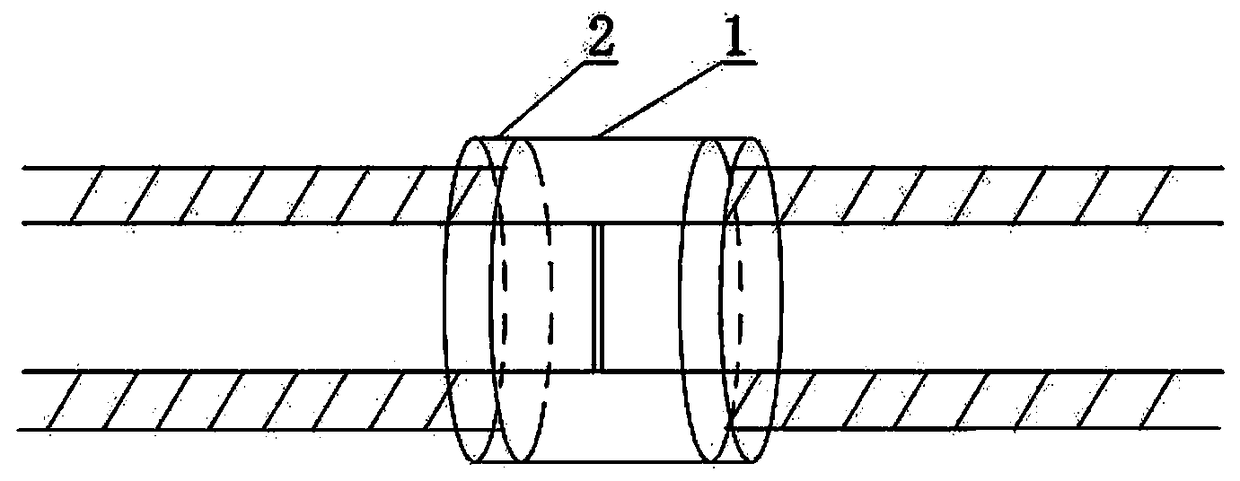

[0030] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the high-seal seamless hot-melt sleeve also includes: a hard sleeve 3, which is tubular and covered at the edges of both ends of the PE short pipe 1, , the nozzle at the other end is provided with a guide crack 31, and the tube body of the hard sleeve 3 is a corrugated structure 32.

[0031] The inner diameter of the hard set is greater than the outer diameter of the PE short pipe 1 by 20±5mm, and the height of the corrugated structure 32 on the tube body of the hard set is greater than 40±5mm when it shrinks. The hard set 3 is made of a metal alloy material, such as aluminum Alloy or zinc alloy, etc., hard kit 3 and PE nozzle are bonded together by adhesive, the bonding method is point bonding, and 3 points or 4 points are set at intervals on the outer layer of the nozzle of PE short pipe 1 position, apply adhesive, the total coating area is 1-2cm 2 , the adhesion force is 20-...

Embodiment 3

[0033] The specific manufacturing steps for preparing the high-seal seamless hot-melt sleeve in Example 1 of the present invention are as follows: select the PE short pipe 1 with the same diameter and wall thickness as the direct-buried pipe outer layer PE pipe to expand the pipe, and directly bury the outer layer of the thermal insulation pipe The pipe is a PE pipe, the middle layer is an insulation layer, the inner layer is a working pipe, and the length of the PE short pipe 1 is 500-1000mm. Pipe expansion by cold expansion process: PE short pipe 1 enters from the small end of the different diameter pipe mold, the large end of the different diameter pipe mold is 10mm larger than the inner diameter of PE short pipe 1, and the PE short pipe 1 is made by pressing the press The big end of the reducing pipe mold passes through, the pressure setting range of the press is related to the specification of the PE short pipe 1, the inner diameter (DN) of the PE short pipe 1: 100≤DN4 -5×...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com