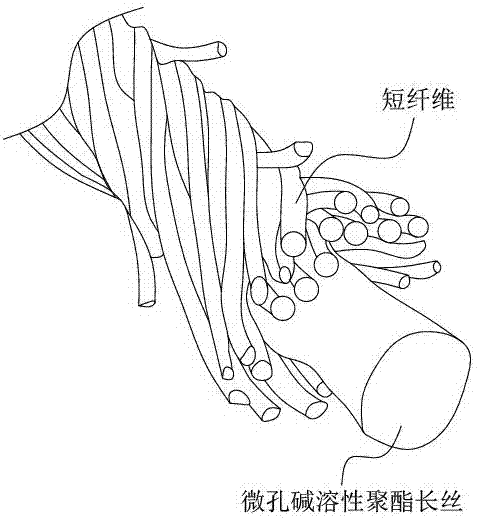

Method for preparing hollow textile from core spun yarn with microporous alkali-soluble polyester filament covered with short fiber

An alkali-soluble polyester, staple fiber technology, applied in the direction of single-component polyester rayon, microsphere preparation, textile and papermaking, etc., can solve the problem of incomplete dissolution, not widely used, PVA filament fiber It takes a long time to dissolve and other problems, so as to achieve the effect of keeping warm and quick-drying, complete dissolution and fast dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Embodiment 1, the present invention will be described by taking the microporous alkali-soluble FDY filament as an example, specifically:

[0107] 1. Preparation of foamed microcapsules:

[0108] 11. Place dimethyl terephthalate, ethylene glycol, dimethyl isophthalate-5-sodium sulfonate, polyethylene glycol, and tetrabutyl titanate in a slurry pot and stir to mix evenly. Obtain the microcapsule wall material raw materials; wherein, in the microcapsule wall material raw materials, dimethyl terephthalate, ethylene glycol, dimethyl isophthalate-5-sodium sulfonate, polyethylene glycol, tetrabutyl titanate The weight parts of ester are successively:

[0109] Dimethyl terephthalate 70%

[0110] Ethylene glycol 15%

[0111] Sodium Dimethyl Isophthalate-5-sulfonate 10%

[0112] Polyethylene glycol 4.3%

[0113] Tetrabutyl titanate 0.7%;

[0114] 12. Transfer the microcapsule wall material raw materials stirred and mixed in step 11 into an esterification pot for esterificat...

Embodiment 2

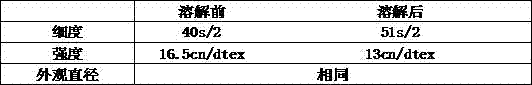

[0137] Embodiment 2. Prepare microporous alkali-soluble filaments with a microporous structure according to the process steps and process parameters in Example 1. The parameters of the microporous alkali-soluble filaments are: 30D / 36F. Porous alkali-soluble long filament peripheral coating cotton fiber, to obtain the core-spun yarn of cotton fiber bag microporous alkali-soluble long filament, the specification of core-spun yarn is: 40s / 2, and the twist coefficient of core-spun yarn is 320; The core-spun yarn is dissolved in a NaOH solution with a concentration of 3 g / L for 60 minutes, and the dissolution temperature is 105 degrees. After dissolving, the cotton fiber hollow yarn can be obtained; wherein, the core-spun yarn of cotton fiber wrapped with microporous alkali-soluble filaments The comparison before and after dissolution is shown in the table below:

[0138]

[0139] It should be further pointed out that the hollow yarn in Example 2 can be directly used as yarn for...

Embodiment 3

[0140] Example 3, according to the process steps and process parameters of Example 1, microporous alkali-soluble filaments with a microporous structure were prepared. The parameters of the microporous alkali-soluble filaments were: 50D / 36F, and were spun into microporous Cotton fibers are covered with porous alkali-soluble filaments to obtain core-spun yarns covered with microporous alkali-soluble filaments. The specifications of the core-spun yarns are: 32s, and the twist coefficient of the core-spun yarns is 320; The core-spun yarn is woven into a single-sided plain weave fabric, and finally the single-sided plain weave fabric is placed in a NaOH solution with a concentration of 2 grams per liter and dissolved for 40 minutes at a temperature of 105 degrees. After dissolving, it is dyed and finished. Hollow fabrics can be obtained; Among them, the comparison of single-sided plain fabrics before and after dissolution is as follows:

[0141]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com