Preparation technology of modified calcium carbonate for plastic

A preparation process and calcium carbonate technology, applied in the field of modified calcium carbonate preparation, can solve the problems of calcium carbonate hydrophilic and oleophobic, poor dispersibility, poor plastic compatibility, etc., and achieve good modification effect, good dispersibility, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

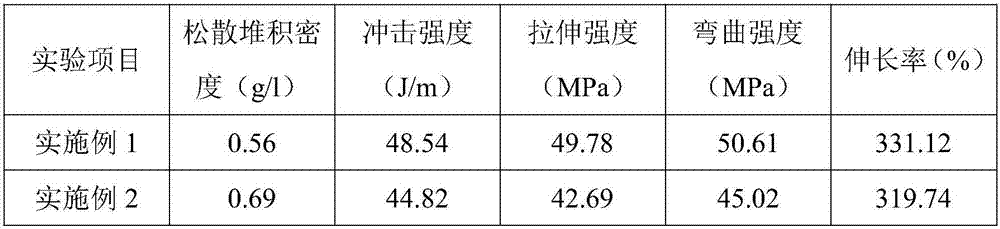

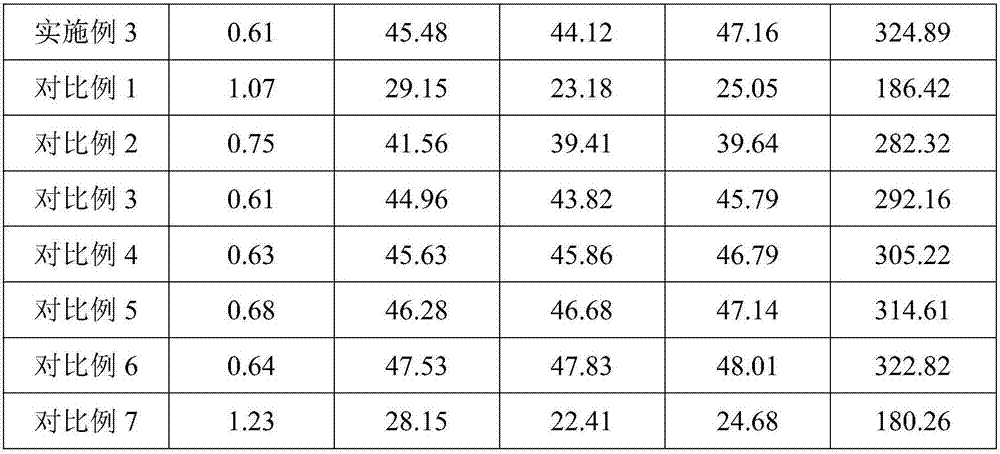

Examples

preparation example Construction

[0027] The preparation technology of described modified calcium carbonate, comprises the following steps:

[0028] S1: Grinding the calcium carbonate, passing through a 1000-1500 mesh sieve, and drying at a temperature of 85-90°C until the water content is ≤0.5%, to obtain a calcium carbonate pulverized product;

[0029] S2: Add the crushed calcium carbonate obtained in step S1 into a high-speed mixer, and then add triethanolamine oleic acid soap, dicyclohexyl peroxydicarbonate, trimethylolpropane tris(3-aziridinylpropane) Ester), aluminum triacetylacetonate, molecular sieve catalyst, heated up to 53-68 ° C, and stirred at a high speed of 1300-1500r / min for 40-60min to prepare mixture A;

[0030] S3: Add potassium diethylenetriaminepentacarboxylate, acrylate regulator, diisodecyl phthalate, and hexenyl bisstearamide to the mixture A prepared in step S2, and control the temperature at 70-86 °C, stirring at a high speed of 1000-1200r / min for 30-40min to prepare mixture B;

[0...

Embodiment 1

[0036] A high-performance plastic prepared by using modified calcium carbonate, which includes the following raw materials in parts by weight: 70 parts of polyvinyl chloride, 32 parts of modified calcium carbonate, 3 parts of nylon, 4 parts of chlorinated paraffin, 5 parts of borax, 2 parts of antistatic agent, 3 parts of mineral oil;

[0037] The modified calcium carbonate, in parts by weight, comprises the following raw materials: 172 parts of calcium carbonate, 5.6 parts of triethanolamine oleic acid soap, 0.1 part of dicyclohexyl peroxydicarbonate, trimethylolpropane three (3- Aziridinyl propionate) 0.7 parts, aluminum triacetylacetonate 0.2 parts, molecular sieve catalyst 0.1 parts, potassium diethylene triamine pentacarboxylate 0.8 parts, acrylate regulator 0.3 parts, diisodecyl phthalate 2 parts, 0.6 parts of hexenyl bis stearamide, 0.6 parts of 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole, N-ethyl-5 - 0.5 part of methyl-2-(1-methylethyl) cyclohexane...

Embodiment 2

[0046] A high-performance plastic prepared by using modified calcium carbonate, comprising the following raw materials in parts by weight: 56 parts of polyvinyl chloride, 28 parts of modified calcium carbonate, 2 parts of nylon, 3 parts of chlorinated paraffin, 4 parts of borax, 1.2 parts of antistatic agent, 2.5 parts of mineral oil;

[0047] The modified calcium carbonate, in parts by weight, comprises the following raw materials: 143 parts of calcium carbonate, 4.4 parts of triethanolamine oleic acid soap, 0.1 part of dicyclohexyl peroxydicarbonate, trimethylolpropane three (3- Aziridinyl propionate) 0.5 parts, aluminum triacetylacetonate 0.2 parts, molecular sieve catalyst 0.1 parts, potassium diethylene triamine pentacarboxylate 0.6 parts, acrylate regulator 0.2 parts, diisodecyl phthalate 1.5 parts, 0.4 parts of hexenyl bis stearamide, 0.4 parts of 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole, N-ethyl-5 - 0.3 part of methyl-2-(1-methylethyl) cyclohexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com