Method for preparing modified porous starch by using pulsed electric field

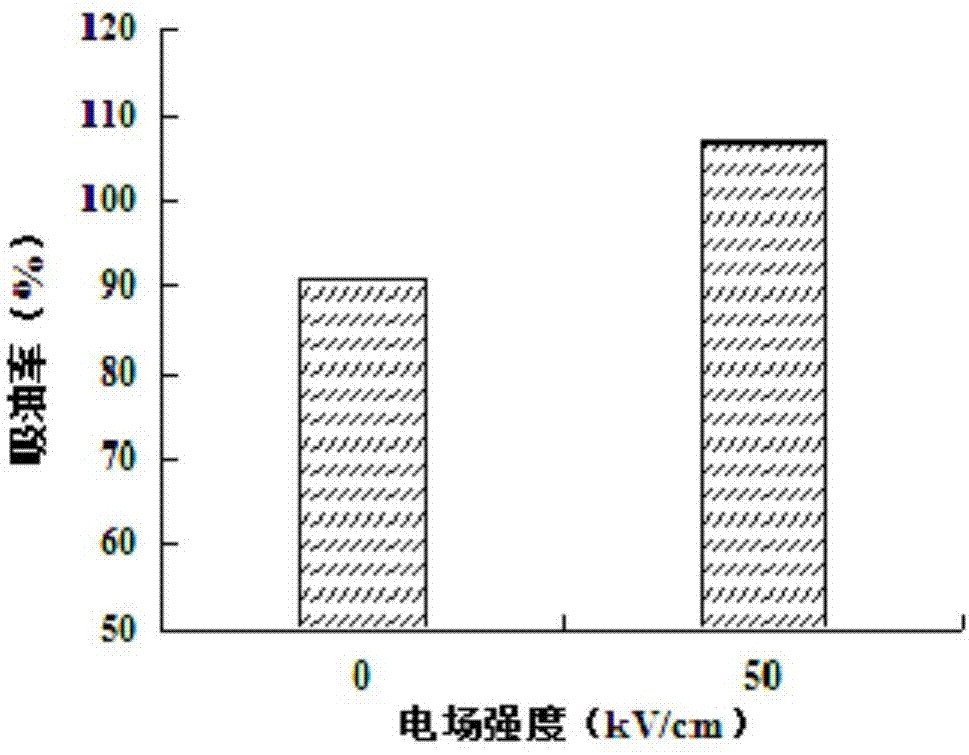

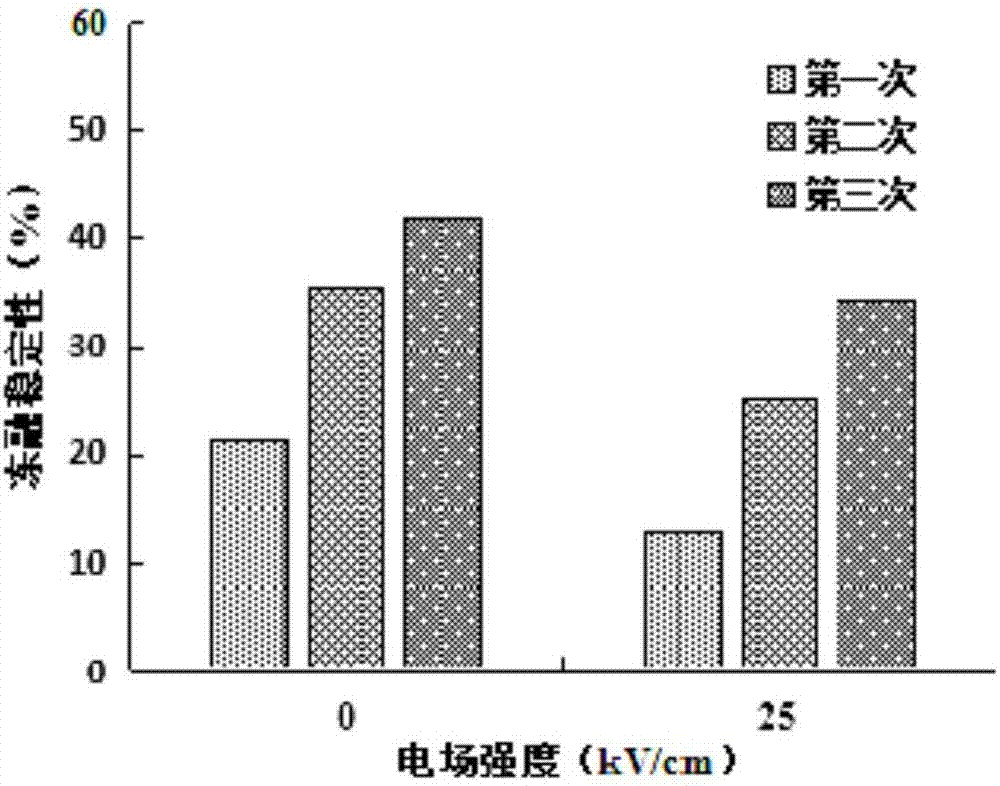

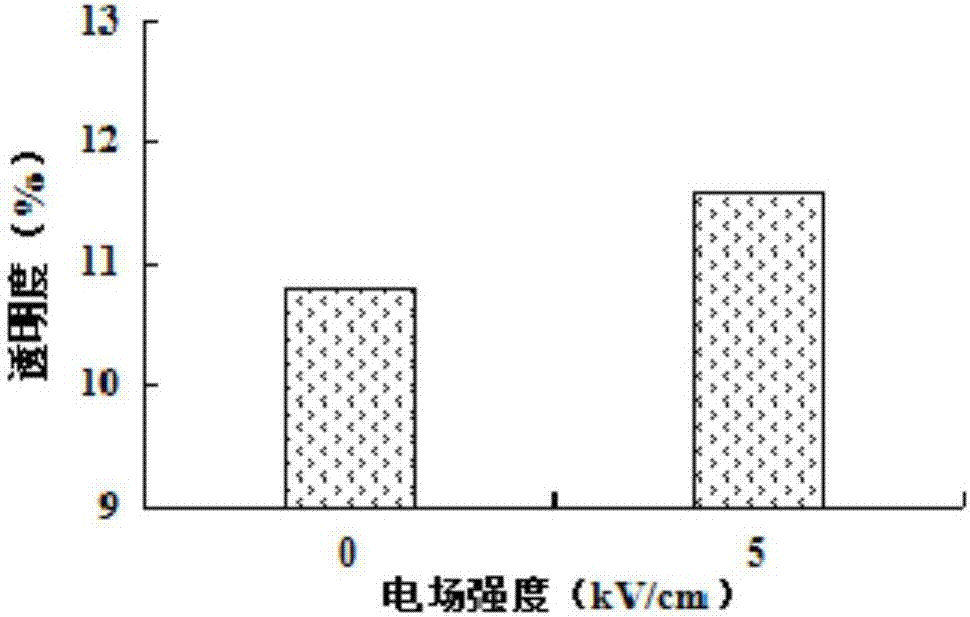

A technology of porous starch and pulsed electric field, applied in the fields of application, food electrical processing, food science, etc., can solve the problems that are not involved, and achieve the effect of reducing reaction time, good oil absorption performance, good embedding and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038](1) Prepare sweet potato raw starch and acetic acid buffer solution of pH 4.5 to form starch milk with a mass ratio concentration of 10%, and add 0.5% α-amylase (based on starch dry basis), and stir at a constant temperature and speed at 50°C Enzymolysis for 3h. Use 2 mol / L hydrochloric acid solution to adjust the pH of the system to 1-2 to terminate the reaction, wash the starch milk three times, dry in an oven at 50°C, and pulverize through a 200-mesh sieve to obtain the original porous starch.

[0039] (2) The porous sweet potato starch prepared in (1) and distilled water are configured into a suspension (1.0 kg in total) with a mass concentration of 40% (w / v), and after stirring for 60 min, add a few drops of 2mol / L potassium chloride The solution adjusts the conductivity of the starch milk to 1000 μS / cm. Adjust the flow rate of the constant current pump to 250mL / min to pump the mixed starch milk into the pulse electric field device (SY-50, Guangzhou Yunxing Scienti...

Embodiment 2

[0048] (1) Prepare ordinary corn raw starch and acetic acid buffer solution of pH 5.5 to form starch milk with a mass ratio concentration of 15%, and add 1% α-amylase (based on starch dry basis), at a constant temperature and constant speed at 50°C Stir for enzymatic hydrolysis for 6h. Use 2 mol / L hydrochloric acid solution to adjust the pH of the system to 1-2 to terminate the reaction, wash the starch milk 5 times, dry in an oven at 45°C, and pulverize through an 80-mesh sieve to obtain the original porous starch.

[0049] (2) The porous cornstarch prepared in step (1) and water are configured into a suspension (1.0 kg in total) with a mass concentration of 30% (w / v), and after stirring for 40 minutes, add a few drops of 1mol / L sodium chloride The solution adjusts the conductivity of the starch milk to 500 μS / cm. Adjust the constant flow pump flow rate to 150mL / min to pump the mixed starch milk into the pulse electric field device (SY-50, Guangzhou Yunxing Scientific Instru...

Embodiment 3

[0051] (1) Prepare common wheat raw starch and acetic acid buffer solution of pH 6.5 to form starch milk with a mass ratio concentration of 25%, and add 2% α-amylase (based on starch dry basis), at a constant temperature and constant speed at 50°C Stirring and enzymatic hydrolysis for 9h. Use 2mol / L hydrochloric acid solution to adjust the pH of the system to 1-2 to terminate the reaction, wash the starch milk 4 times, dry in an oven at 40-50°C, and pulverize through a 200-mesh sieve to obtain the original porous starch.

[0052] (2) The porous wheat starch prepared in step (1) and water are configured into a suspension (1.0 kg in total) with a mass concentration of 25% (w / v), and after stirring for 20 min, add a few drops of 0.5 mol / L chlorinated Potassium solution adjusted the conductivity of starch milk to 100 μS / cm. Adjust the constant flow pump flow rate to 100mL / min to pump the mixed starch milk into the pulse electric field device (SY-50, Guangzhou Yunxing Scientific I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com