Centralized heating device of printing machine

A technology for centralized heating and printing machines, which is applied to printing machines, printing, general parts of printing machinery, etc., can solve problems such as unstable hot air temperature, and achieve unstable air supply temperature, high heat utilization rate, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

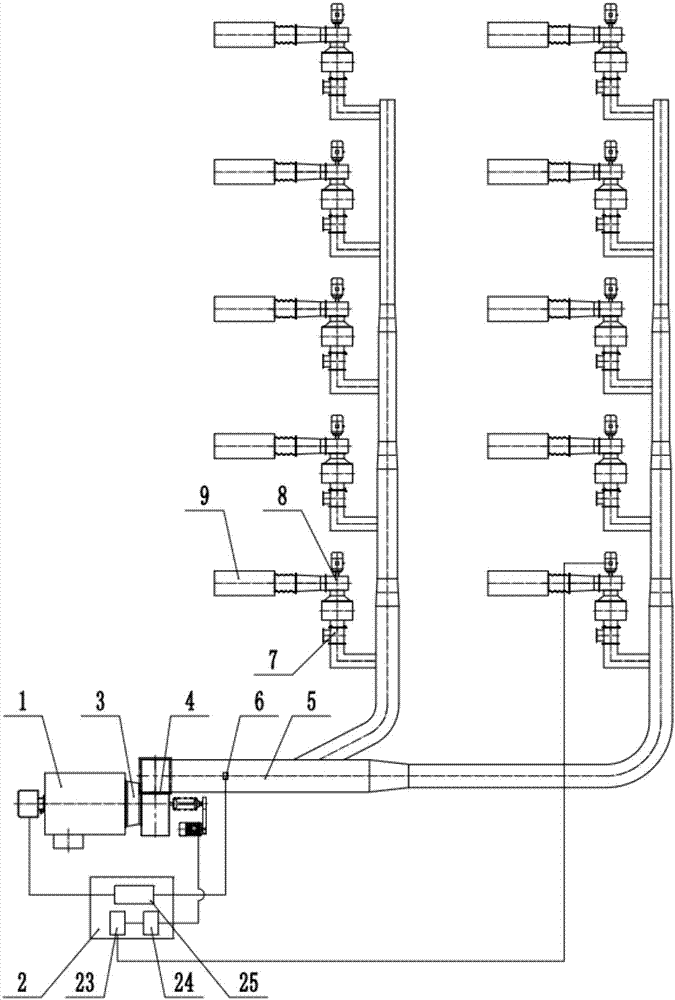

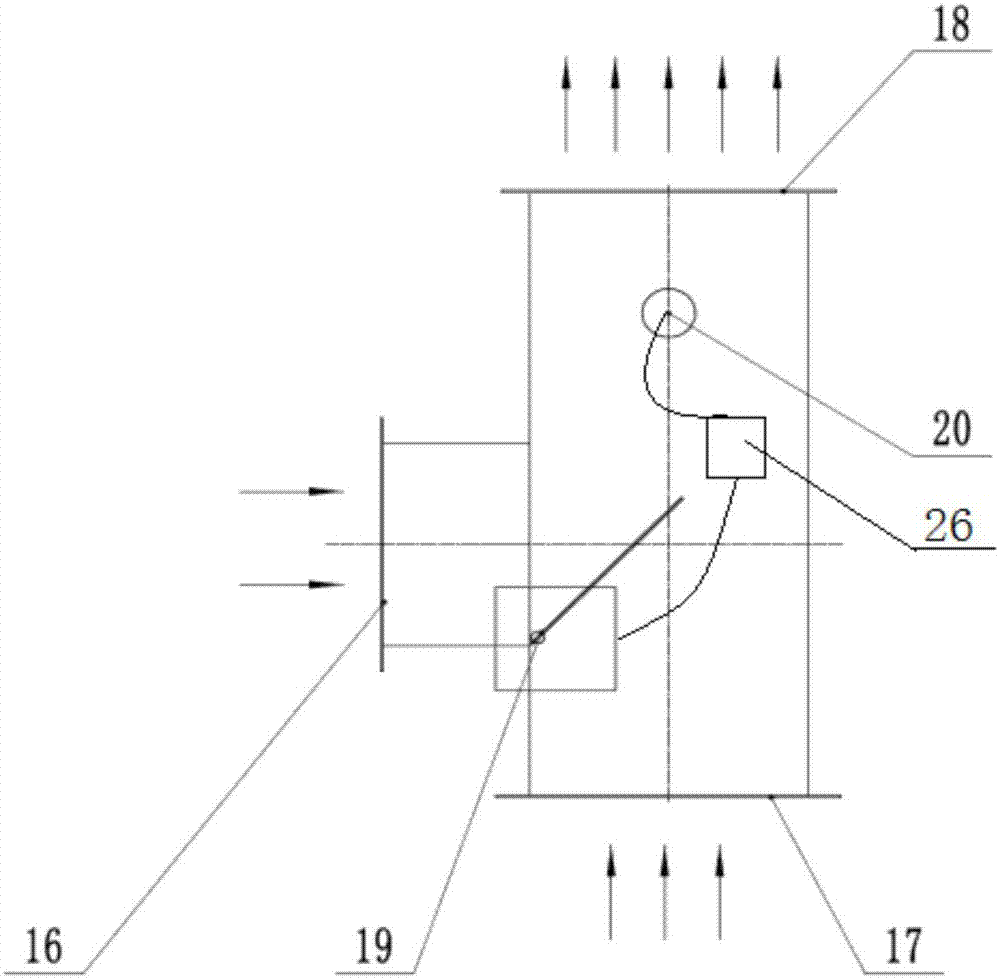

[0017] A central heating device for a printing press provided by the invention has a structure such as figure 1 As shown, it includes a hot blast furnace body 1 fixedly connected in sequence, a connecting air pipe 3, a blower fan 4, and a heating pipeline 5, and also includes a plurality of printing machine color groups 21, and each printing machine color group 21 includes a printing machine color group 21. Machine drying oven 9, printing machine drying oven 9 is connected with oven blower 8, oven blower 8 is communicated with heat supply pipeline 5, each oven blower 8 and heat supply pipeline 5 joints are all installed with temperature control air valve 7, for A temperature sensor 6 is arranged on the heat pipe 5 .

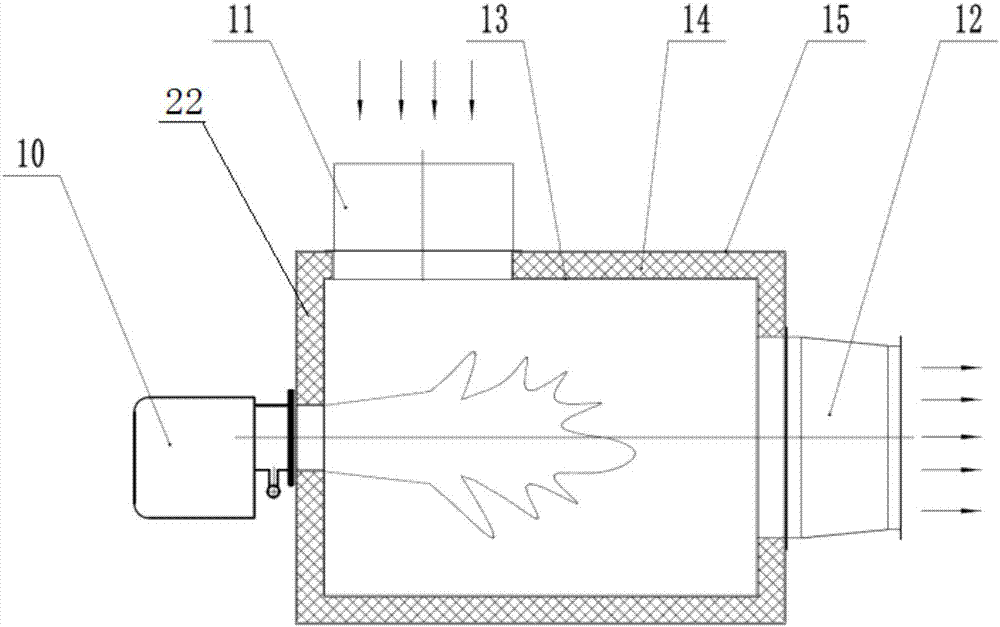

[0018] Such as figure 2 As shown, the hot blast stove body 1 includes a burner 10, the burner 10 is connected with a combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com