Nickel-supported silicon carbide catalyst for reforming reaction of methane and carbon dioxide and its preparation method and application

A carbon dioxide and reforming reaction technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of the decrease of parameters such as specific surface, pore volume and pore diameter, the decrease of catalyst reactivity, low thermal stability, etc. problems, to achieve the effect of being beneficial to dispersion and confinement, improving the ability of anti-carbon deposition, and improving the ability of sintering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

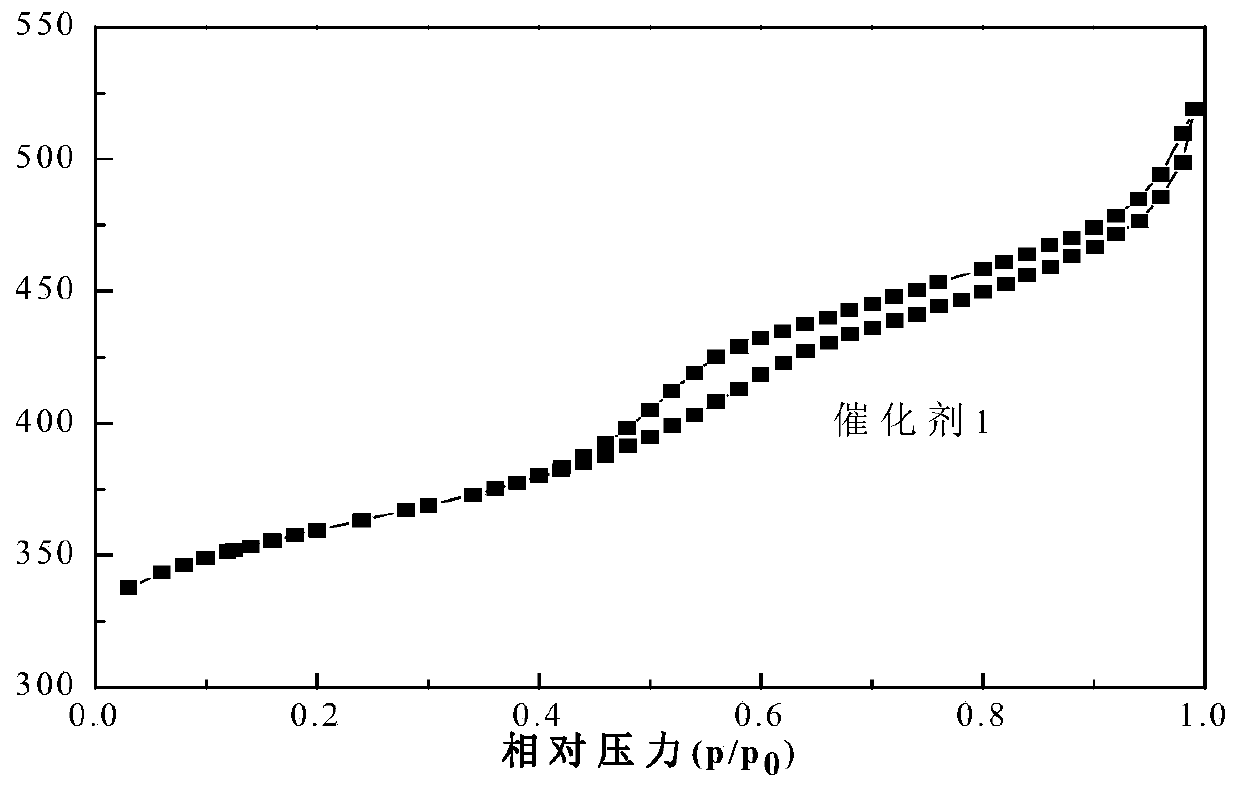

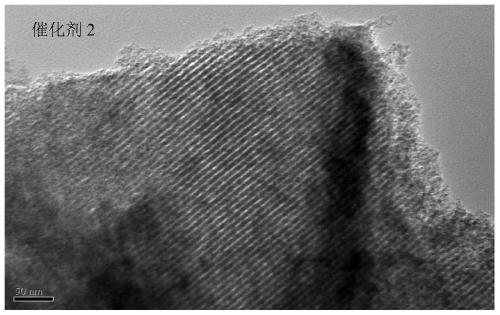

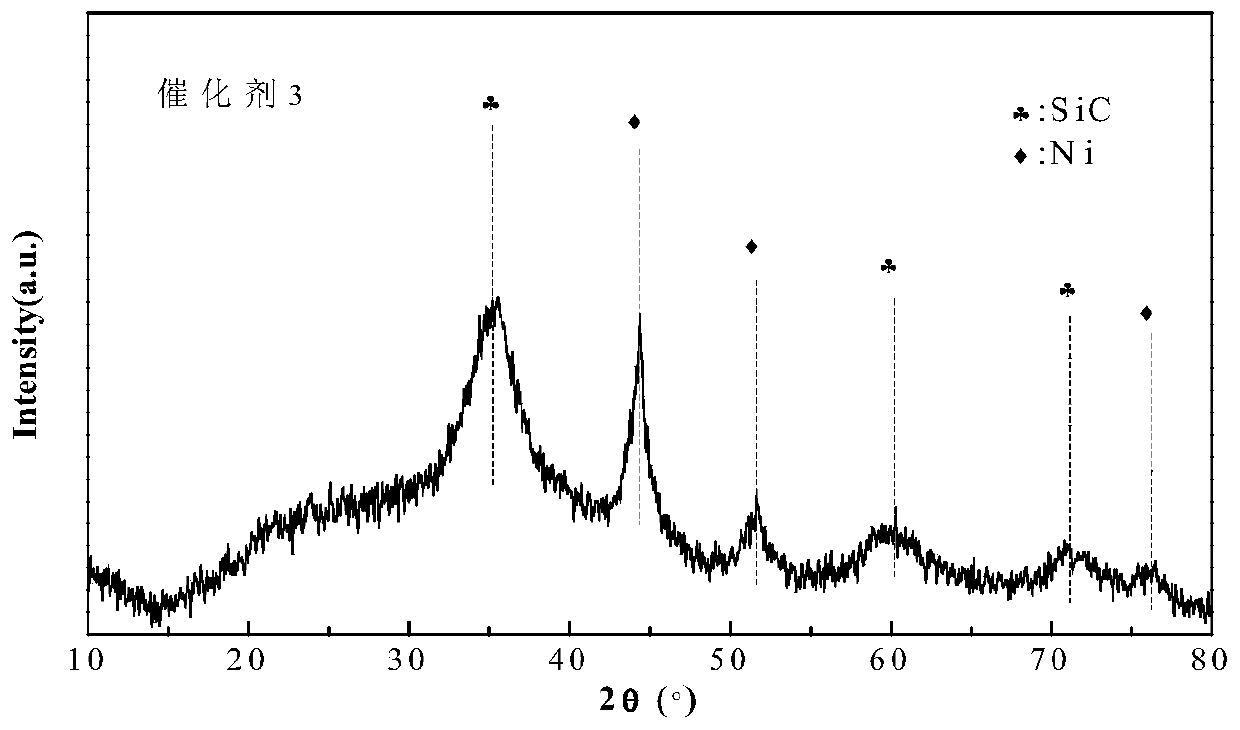

[0039]Example 1: At room temperature, weigh 6g of polysilane and 30g of xylene solution and mix, dissolve under stirring, add 7.2g of mesoporous template raw material SBA-15 after the dissolution is complete, and stir until the xylene evaporates by vacuum rotary evaporation Finished, get sample 1. Sample 1 was dried in an oven at 80°C for 24 hours. Then heated to 200°C at a heating rate of 1°C / min under a nitrogen atmosphere and kept for 5h, then heated to 600°C at a heating rate of 0.5°C / min and kept for 1h to crosslink and pyrolyze polysilane, and finally heated at 1°C / min heating rate was heated to 1200 °C and kept for 3h to obtain sample 2. Take 10g of sample 2 and add it to 50mL of a mixture of ethanol, water and hydrofluoric acid with a volume ratio of 1:1:0.5, stir for 12 hours, then filter and wash with water, and finally dry at 80°C for 24 hours to obtain the SBA-15-like Ordered mesoporous silicon carbide support m-SiC-1 with template pore structure. Weigh 0.33g o...

Embodiment 2

[0040] Example 2: At room temperature, weigh 6.0 g of polycarbosilane and 60 g of xylene solution, mix them, and dissolve them under stirring. After the dissolution is complete, add 5.0 g of mesoporous template material KIT-6, and use magnetic stirring until the xylene is basically volatilized Sample 1 is obtained. Sample 1 was moved into a drying oven at 100°C for 18 hours. Then heated to 300 °C at a heating rate of 2 °C / min under a nitrogen atmosphere and kept for 4 h, then heated to 700 °C at a heating rate of 0.5 °C / min and kept for 2 h to cross-link and pyrolyze polycarbosilane, and finally with 2 The heating rate of °C / min was heated to 1250 °C and kept for 2 h to obtain sample 2. Take 10g of sample 2 and add it to 225mL of a mixture of ethanol, water and hydrofluoric acid with a volume ratio of 1:1:1, stir for 18h, then filter and wash with water, and finally dry at 100°C for 18h to obtain the KIT-6-like Ordered mesoporous silicon carbide support m-SiC-2 with template...

Embodiment 3

[0041] Example 3: At room temperature, weigh 6.0 g of polymethylsilane and 90 g of xylene solution, mix them, and dissolve them under stirring. After the dissolution is complete, add 4.0 g of mesoporous template material MCM-41, and stir until two The toluene was basically volatilized, and sample 1 was obtained. Sample 1 was moved into a drying oven at 110°C for 16 hours. Then heated to 350°C at a heating rate of 4°C / min under a nitrogen atmosphere and kept for 2h, then heated to 800°C at a heating rate of 1°C / min for 3h to crosslink and pyrolyze polymethylsilane, and finally Sample 2 was obtained by heating at a heating rate of 4°C / min to 1300°C and maintaining it for 2.5h. Take 10g of sample 2 and add it to 300mL of a mixture of ethanol, water and hydrofluoric acid with a volume ratio of 1:1:2, stir for 20 hours, then filter and wash with water, and finally dry at 110°C for 16 hours to obtain MCM-41-like Ordered mesoporous silicon carbide support m-SiC-3 with template pore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com