Preparation method of black TiO2 coating

A black titanium dioxide and coating technology, which is applied in the field of photocatalytic materials, can solve the problems of low possibility and influence of continuous processing, and achieve the characteristics of changing energy band and light response range, improving absorption, and improving visible/infrared photocatalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

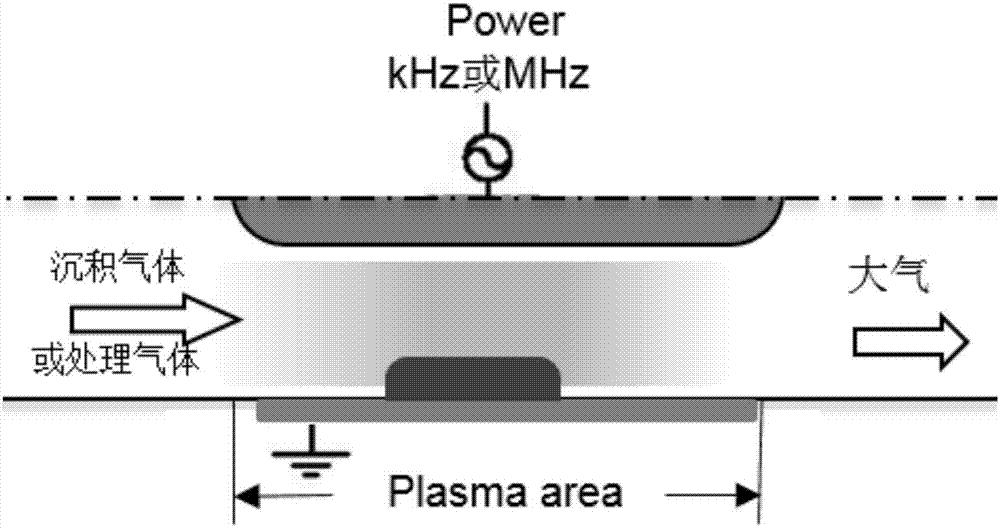

[0034] At a quartz substrate temperature of 200°C (the discharge gap of the barrier discharge plasma reactor is 2 mm), the titanium dioxide coating is first vapor-deposited by atmospheric pressure plasma, Ar:O2 :Ar(TiCl 4 ) flow rates were 950:10:20 (sccm), the deposition time was 20 min, the plasma frequency was 60 kHz, and the voltage was 10000 v.

[0035] After the deposition is over, turn off the kHz power supply and the deposition reaction gas, cool to room temperature, replace with a 13.56MHz RF plasma power supply, and mix He / H 2 The mixed gas is passed into the reaction chamber at a ratio of 50:1, treated at 50W for 10 minutes, and the black titanium dioxide coating is taken out.

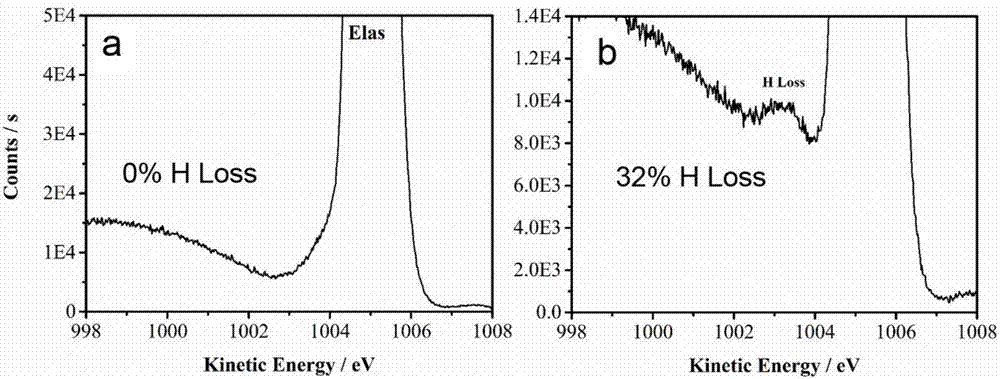

[0036] Optical image of TiO2 coating figure 2 shown. The absorbance of the titanium dioxide coating before and after treatment was characterized by a UV-vis spectrophotometer. It can be seen that the as-deposited untreated TiO coating is white, reflecting the TiO 2 Typical visible ultra...

Embodiment 2

[0038] At a quartz substrate temperature of 180°C (the discharge gap of the barrier discharge plasma reactor is 2mm), the titanium dioxide coating is first vapor-deposited by atmospheric pressure plasma, Ar:O 2 :Ar(TiCl 4 ) flow rates were 500:10:10 (sccm), the deposition time was 30 min, the plasma frequency was 30 kHz, and the voltage was 20000 v.

[0039] After the deposition is over, turn off the kHz power supply and the deposition reaction gas, cool to room temperature, replace with a 1MHz radio frequency plasma power supply, and mix He / H 2 The mixed gas is passed into the reaction chamber at a ratio of 15:1, treated at 160W for 30 minutes, and the black titanium dioxide coating is taken out.

[0040] The optical photos and visible ultraviolet absorption spectra before and after treatment are as follows: Figure 4 , it can be seen that the deposited titanium dioxide coating has only extremely low absorption in the visible and infrared parts, while the treated black tita...

Embodiment 3

[0042] Metallic nickel foam is deposited at a temperature of 100°C (the discharge gap of the barrier discharge plasma reactor is 2 mm), and the titanium dioxide coating is first vapor-deposited by atmospheric pressure plasma, Ar:O 2 :Ar(TiCl 4 ) flows were 300:2:10 (sccm), the deposition time was 40min, the plasma frequency was 100kHz, and the voltage was 10000v.

[0043] After the deposition is over, turn off the kHz power supply and the deposition reaction gas, cool to room temperature, replace with a 27MHz RF plasma power supply, and mix He / H 2 The mixed gas is passed into the reaction chamber according to the ratio of 30:1, 100W is used for 30 minutes, and the black titanium dioxide coating is taken out.

[0044] Figure 5 As shown, the optical photographs of the metal foam titanium dioxide coating before and after treatment show that the coating before treatment is white, and the coating after treatment is obviously blackened.

[0045] From Figure 5 It can also be fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com