Special fixing tool for power transformation equipment sulfur hexafluoride gas detection

A technology for sulfur hexafluoride gas and power transformation equipment, which is applied in the analysis of gas mixtures, structural details of gas analyzers, and measurement devices, etc. Handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

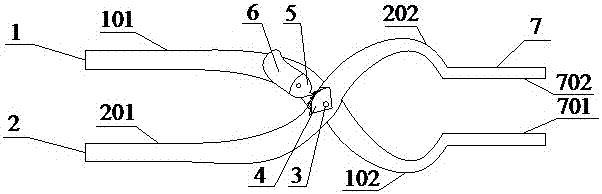

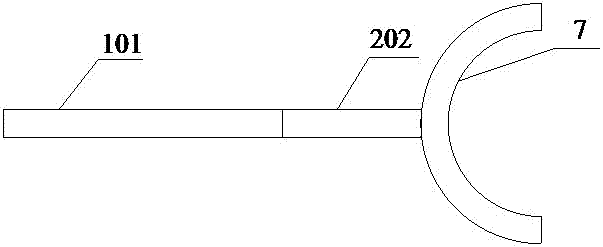

[0055] refer to Figure 1~2 , a special fixing tool for detecting sulfur hexafluoride gas in power transformation equipment, a first clamp body 1 and a second clamp body 2, the first clamp body and the second clamp body are connected by a pin shaft 3, on the pin shaft A torsion spring is set, a ratchet 4 is fixedly arranged on the second caliper body, a pawl 5 and a pawl control button 6 are arranged on the first pliers body, the pawl is fixedly connected with the pawl control button, and the torsion spring One end of the pliers body is in contact with the second pliers body, and the other end is in contact with the pawl control button, and the first pliers body and the second pliers body respectively include a gripping part (101, 201) and a clamping part (102, 202), the end of the clamping part is provided with a circular arc-shaped pressing part 7, and the first clamp body and the second clamp body are made of aluminum alloy,

[0056] Among them, the torsion spring is a mec...

Embodiment 2

[0080] The structure of the special fixing tool for detecting sulfur hexafluoride gas in the substation equipment in this embodiment is basically the same as that in Embodiment 1, except that:

[0081] The aluminum alloy is made of the following components in mass percentage:

[0082] Mg: 2.8%;

[0083] Si: 4.2%;

[0084] Mn: 0.28%;

[0085] Cr: 0.16%;

[0086] Zr: 0.23%;

[0087] Ti: 0.38%;

[0088] Yb: 0.25%;

[0089] The balance is Al and impurities with a content of ≤0.05%.

[0090] The preparation method of the aluminum alloy comprises the following steps:

[0091] Step S1: Carry out alloy smelting according to the above composition ratio, the alloy smelting temperature is 735°C, and keep warm for 10 minutes to obtain alloy melt 1;

[0092] Step S2: adding a refining agent to the obtained alloy melt 1 for refining, the refining temperature is 735° C., and the time is 12 minutes to obtain alloy melt 2;

[0093] Step S3: cooling and extruding the molten alloy 2 to ...

Embodiment 3

[0101] The structure of the special fixing tool for detecting sulfur hexafluoride gas in the substation equipment in this embodiment is basically the same as that in Embodiment 1, except that:

[0102] The aluminum alloy is made of the following components in mass percentage:

[0103] Mg: 2.2%;

[0104] Si: 3.6%;

[0105] Mn: 0.23%;

[0106] Cr: 0.12%;

[0107] Zr: 0.20%;

[0108] Ti: 0.36%;

[0109] Yb: 0.18%;

[0110] The balance is Al and impurities with a content of ≤0.05%.

[0111] The preparation method of the aluminum alloy comprises the following steps:

[0112] Step S1: Carry out alloy melting according to the above-mentioned composition ratio, the alloy melting temperature is 725°C, and keep warm for 12 minutes to obtain alloy melt 1;

[0113] Step S2: adding a refining agent to the obtained alloy melt 1 for refining, the refining temperature is 732° C., and the time is 15 minutes to obtain alloy melt 2;

[0114] Step S3: cooling and extruding the molten all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com