Method for rapid on-line monitoring of optimum cure point of solid propellant, and sensor

A solid propellant, vulcanization point technology, applied in the direction of material resistance, etc., to achieve the effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

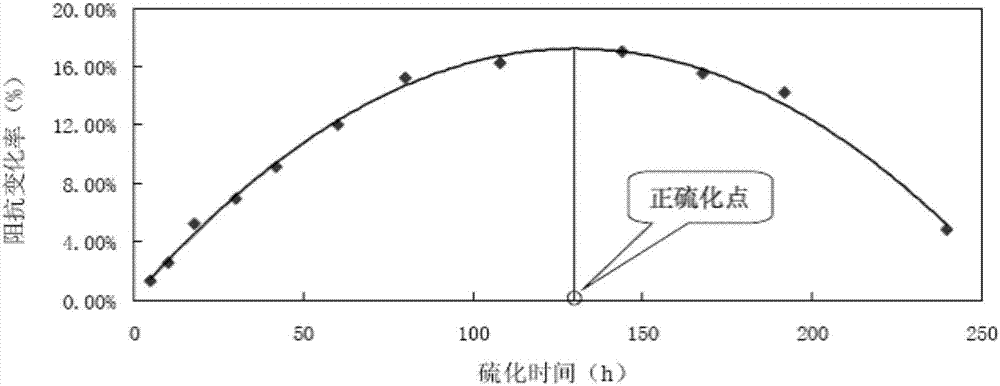

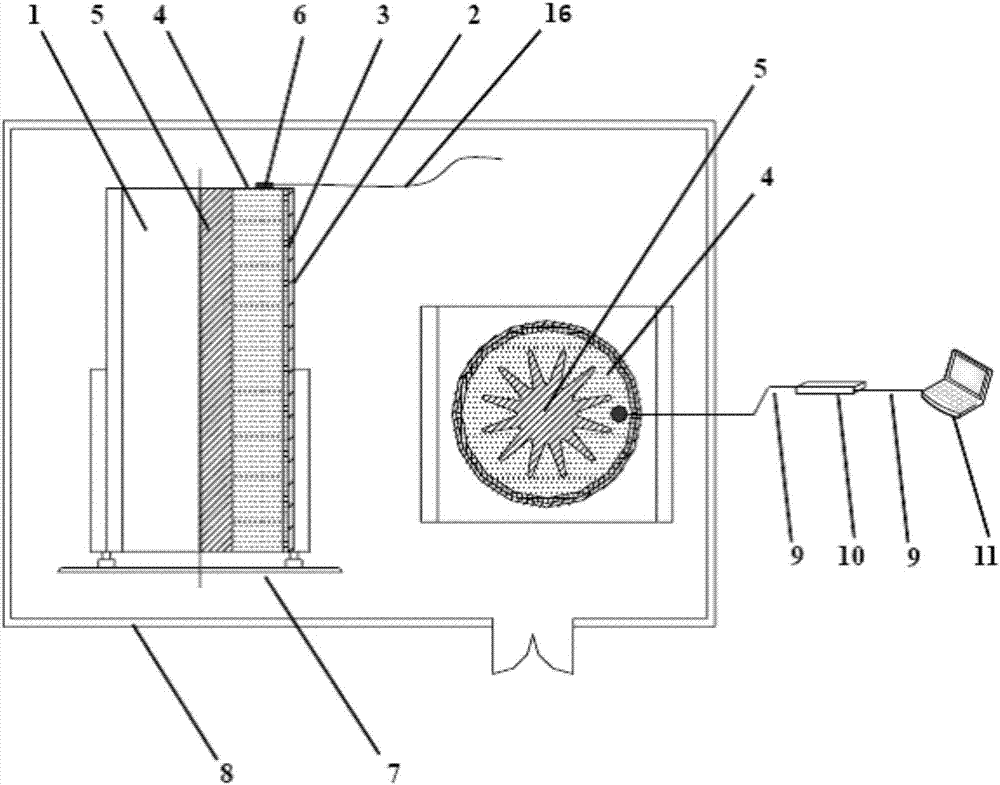

[0029] Example: Monitoring of positive vulcanization point of propellant in a certain type of solid rocket motor

[0030] Implementation steps:

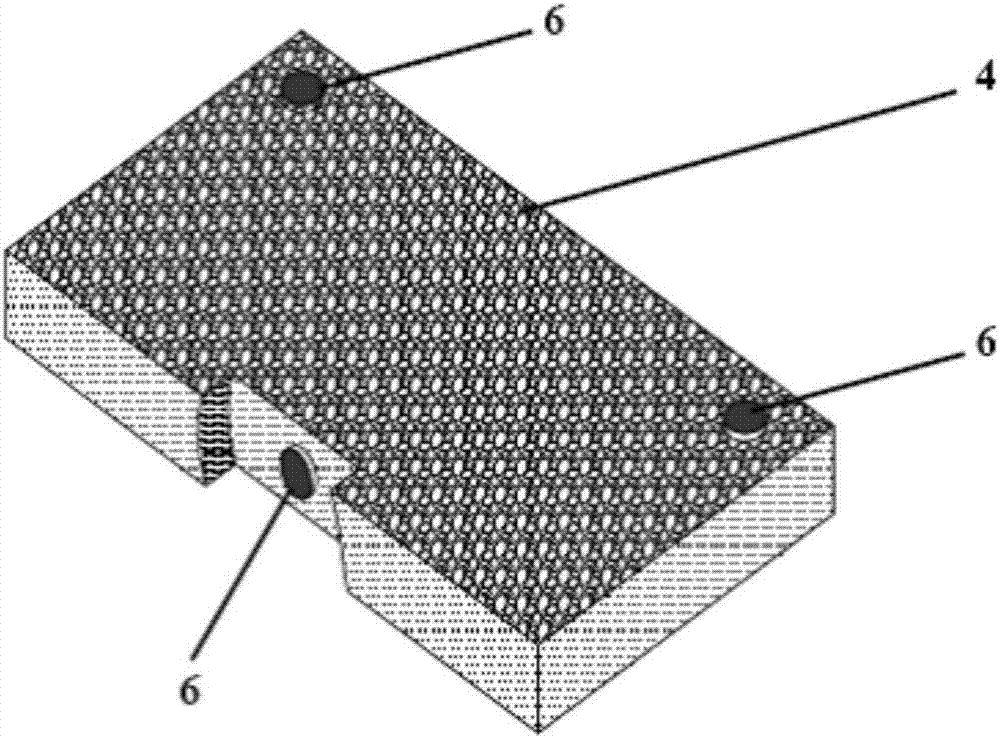

[0031]The size of the combustion chamber of the solid rocket motor is Φ200mm×1500mm, and the propellant for the charge is a kind of hydroxyl-terminated polybutadiene as a binder, toluene diisocyanate as a curing agent, and ammonium perchlorate as an oxidant. A mature propellant with aluminum powder as the combustion agent. The piezoelectric sensor used is a circular chip, the piezoelectric material of the piezoelectric sensor used is lead zirconate titanate piezoelectric ceramics, the electrode material is silver electrode, and the size of the piezoelectric sensor is Φ10mm×0.2mm. The impedance detector used is an impedance analysis board. The temperature condition of the vulcanization process of the solid rocket motor is 70°C. According to the traditional positive vulcanization point monitoring method, the propellant has a positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com