Pulverized coal and exhaust gas hybrid power double-medium boiler

A dual-medium, pulverized coal technology, applied in the field of boilers, can solve the problems of large area of boiler room, large coal consumption, and inhomogeneous combustion, and achieve high exhaust gas temperature, lower fuel cost, and compact overall structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

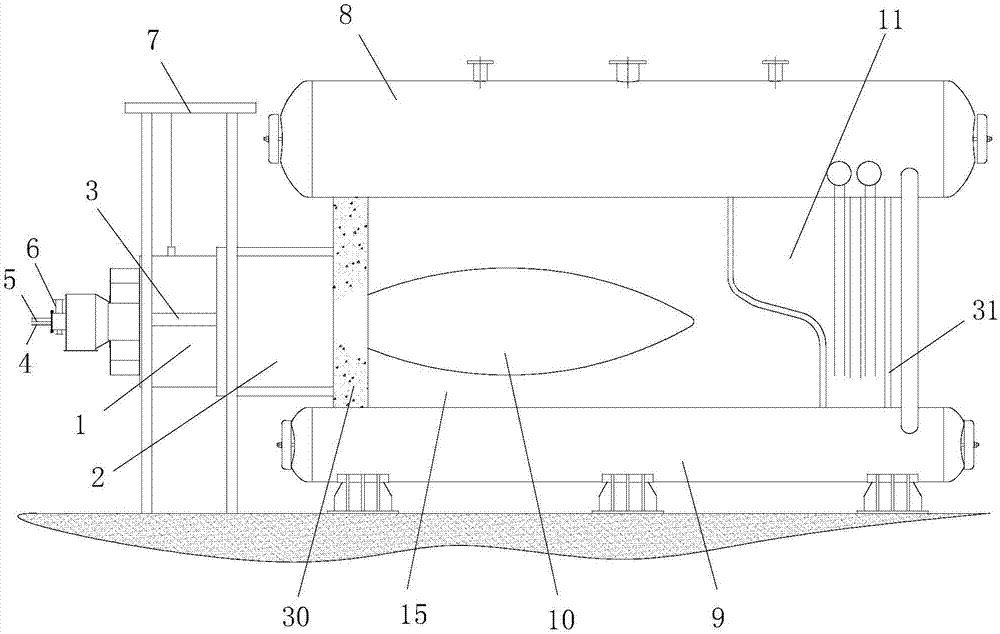

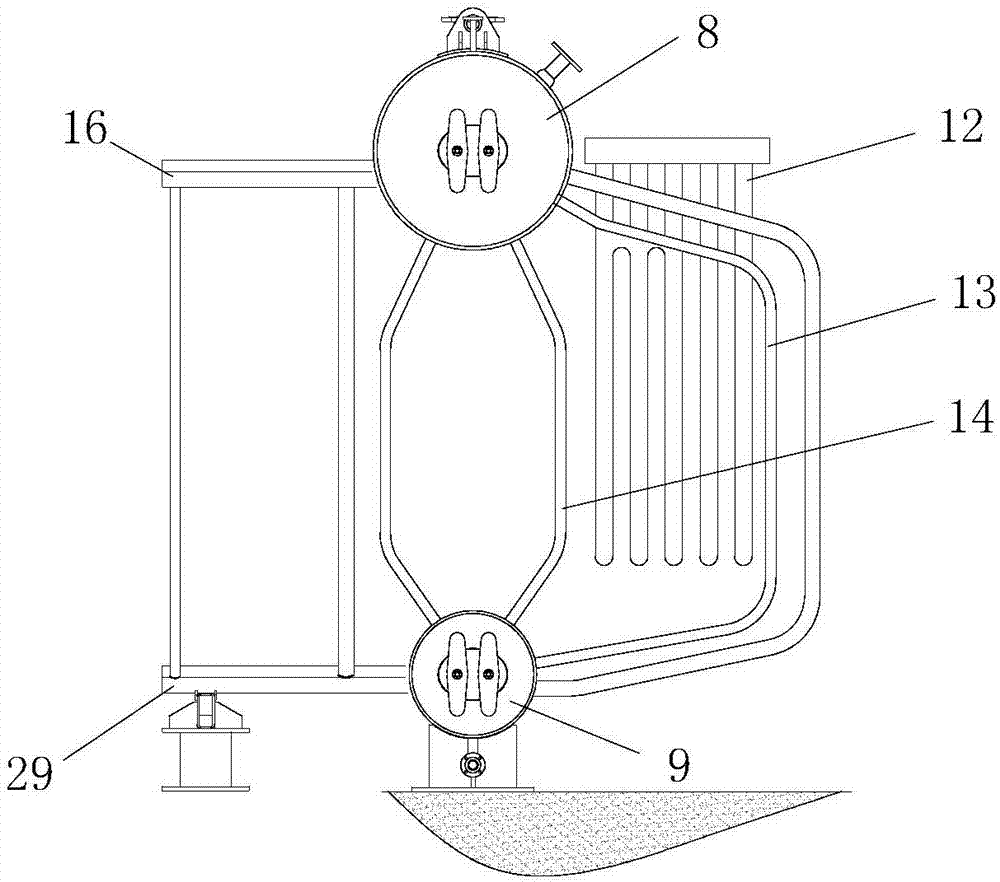

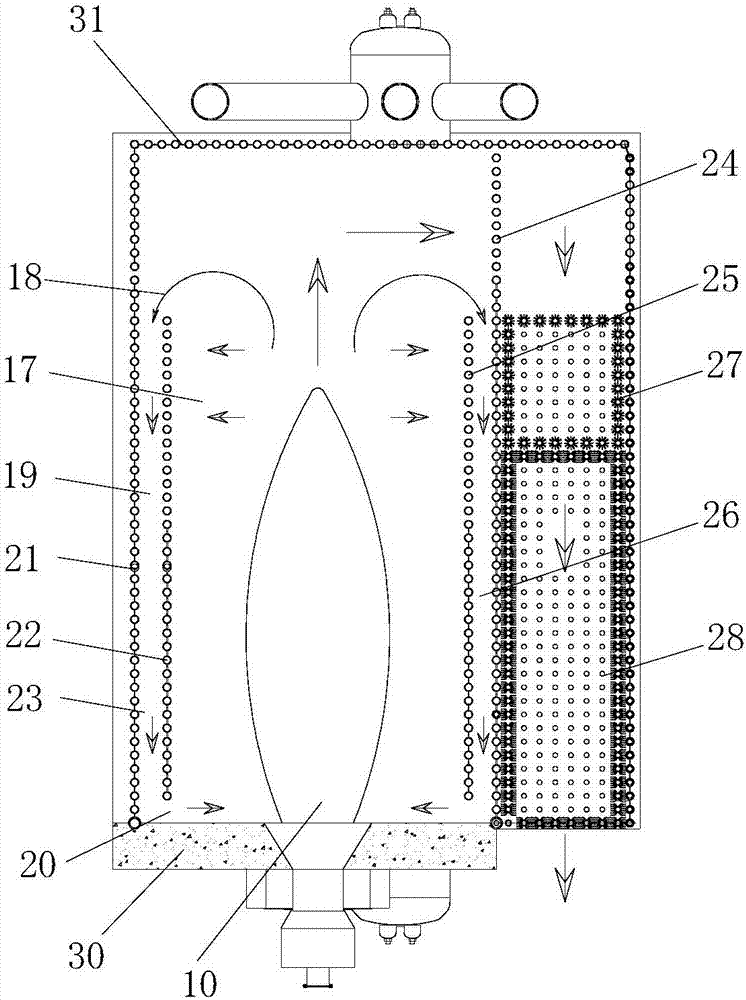

[0031] Such as Figure 1 to Figure 3 As shown, the pulverized coal and exhaust gas mixed dual-power dual-medium boiler, the overall structure of the boiler is a double-drum vertical D-shaped structure.

[0032] The boiler includes a fuel system, a stable combustion chamber, a combustion chamber, a burnout chamber 11, an upper drum 8, a lower drum 9, a heat transfer oil circulation system 12 and a water circulation system. The fuel system is arranged in front of the stable combustion chamber and is a stable combustion chamber. The chamber is supplied with fuel, and the fuel system includes a powder feeding system 5 and an exhaust gas control system 4 . A furnace 15 is arranged between the upper and lower drums, the combustion chamber and the burnout chamber 11 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com