Method for preparing 1,4-sorbitan

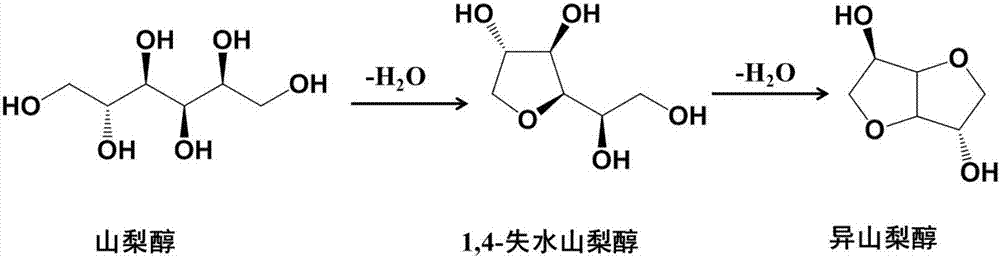

A kind of technology of sorbitan, sorbitol, applied in the field of preparation of 1,4-sorbitan, can solve problems such as increasing catalyst cost, no specific pointing out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 30g of water to the reaction kettle, heat to 40°C, add 3g of sorbitol dropwise into the water under vigorous stirring, after stirring evenly, add 0.3g of sodium bisulfate catalyst, raise the temperature to 140°C, and react for 4h , through liquid chromatography, using the external standard method to test the product, the conversion rate of sorbitol reaches 90%, and the selectivity of the product 1,4-sorbitol reaches 81%.

Embodiment 2~5

[0023] The reaction process of Example 1 was repeated, except that the reaction conditions were different from the used solvent and catalyst. The specific reaction conditions and results of each embodiment are listed in Table 1.

[0024] Table 1, embodiment 2~5 specific reaction conditions

[0025]

Embodiment 6

[0027] Add 50g of methyl isobutyl ketone into the reaction kettle, heat to 60°C, stir vigorously, add the catalyst NaH 2 PO 4 0.2g, after stirring evenly, 3.5g sorbitol was added dropwise to the solvent under the condition of vigorous stirring. The temperature was raised to 160° C., and the reaction was carried out for 6 hours. The product was tested by liquid chromatography and external standard method. The conversion rate of sorbitol was 95%, and the selectivity of the product 1,4-sorbitol reached 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com