Preparation method of high-displacement dealcoholized flame-retardant fireproof sealant

A fireproof sealant, dealcoholized technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem that the anti-displacement ability of sealants cannot meet the needs of practical applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

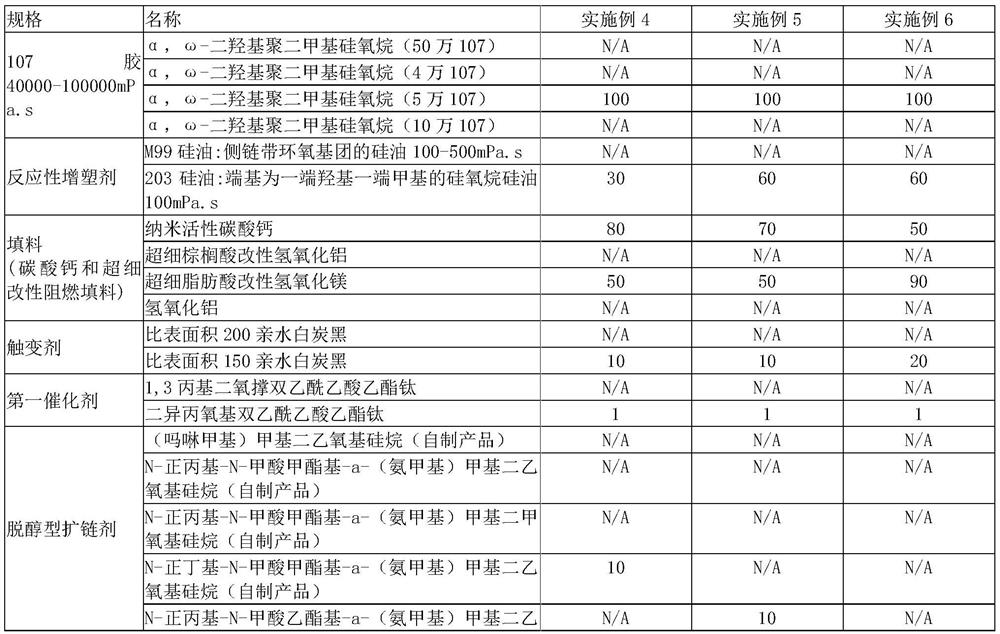

Examples

Embodiment 1

[0028] High-displacement dealcoholized flame-retardant fireproof sealant, in parts by weight, its raw materials include 100 parts of α, ω-dihydroxy polydimethylsiloxane, 5-10 parts of dealcoholized chain extender, reactive plasticizer 30-60 parts of agent, 50-100 parts of calcium carbonate, 40-90 parts of superfine modified flame retardant filler, 25-55 parts of dealcoholization curing agent, 5-20 parts of thixotropic agent and 1 part of the first catalyst.

[0029] The details of raw materials are:

[0030] (1) Dealcohol-type chain extenders include (morpholine methyl) methyldiethoxysilane, N-n-propyl-N-methylformyl-a-(aminomethyl) methyldiethoxy Silane, N-n-propyl-N-carboxymethyl-a-(aminomethyl)methyldimethoxysilane, N-n-butyl-N-carboxymethyl-a-(aminomethyl) Methyldiethoxysilane, N-n-propyl-N-carboxyethyl-a-(aminomethyl)methyldiethoxysilane and N-n-propyl-N-amido-a-( At least one of aminomethyl)methyldiethoxysilanes. The dealcohol-type chain extenders all introduce electron...

experiment example

[0081] Carry out performance test to the product that embodiment and comparative example make, experimental result and experimental method and standard refer to table 5 and table 6.

[0082] Table 5: Relevant test results of Examples 1-6

[0083]

[0084] Table 6: Test results related to Comparative Examples 1-5

[0085]

[0086]

[0087] It can be seen from Examples 1-6 that under the current formula and process requirements, the use of dealcoholized chain extenders, dealcoholized crosslinking agents, and ultrafine modified flame-retardant fillers can meet the performance index requirements, although All characteristics are not described in combination, as long as there is no contradiction in these technical combinations, they should be considered as within the scope of this description

[0088] From comparative example 1, it can be seen that the use of 500,000 viscosity 107 glue and the traditional process of making glue can meet the requirements of low modulus and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com