Manganese-doped BNT-BA lead-free ferroelectric ceramic material and preparation method thereof,

A technology of BNT-BA, ferroelectric ceramics, applied in the field of functional materials, can solve the problem of reduced polarization strength, and achieve the effect of excellent comprehensive electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

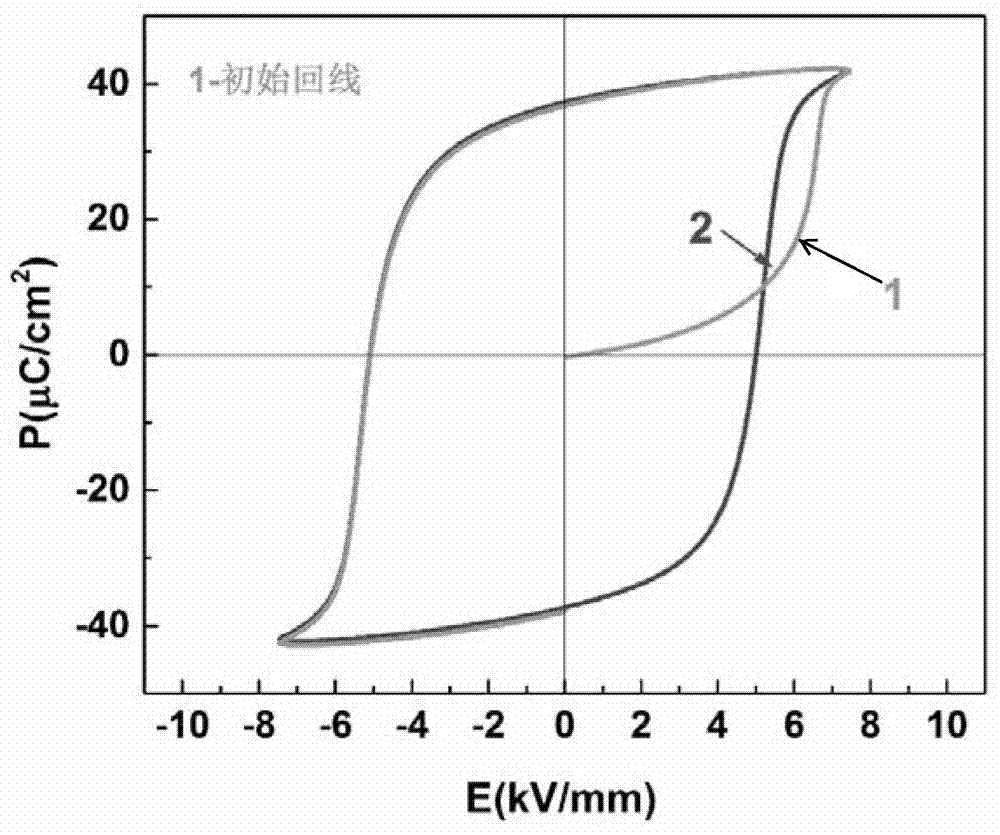

Image

Examples

Embodiment 1

[0039] Embodiment 1: the composition of material is 0.96Bi 0.5 Na 0.5 (Ti 0.997 mn 0.003 )O 3 -0.04BiAlO 3

[0040] By Bi 2 o 3 , NaHCO 3 、TiO 2 、Al 2 o 3 , MnCO 3 Powder as raw material, according to 0.96Bi 0.5 Na 0.5 (Ti 1-x mn x )O 3 -0.04BiAlO 3 The stoichiometric ratio is prepared, mixed by wet ball milling, and mixed for 24 hours according to the mass ratio of raw materials: balls: alcohol = 1:2:0.8, so that the components are mixed evenly. After drying, pass through a 40-mesh sieve, press into large pieces under a pressure of 5MPa, raise the temperature to 850°C at a rate not higher than 2°C / min, keep it warm for 2 hours, and synthesize 0.96Bi 0.5 Na 0.5 (Ti 0.997 mn 0.003 )O 3 -0.04BiAlO 3 of ceramic powder.

[0041] The ceramic powder in step (1) is ground and passed through a 40-mesh sieve. Then mix according to the wet ball milling method, finely grind for 24 hours according to the mass ratio of raw material:ball:alcohol=1:2:0.6, and dry the...

Embodiment 2

[0047] Embodiment 2: the composition of material is 0.96Bi 0.5 Na 0.5 (Ti 0.993 mn 0.007 )O 3 -0.04BiAlO 3

[0048] Repeat the preparation method of Example 1 by the above-mentioned formula.

[0049] The hysteresis loop was tested at room temperature for the ceramic material of this example, and the results are shown in Table 1.

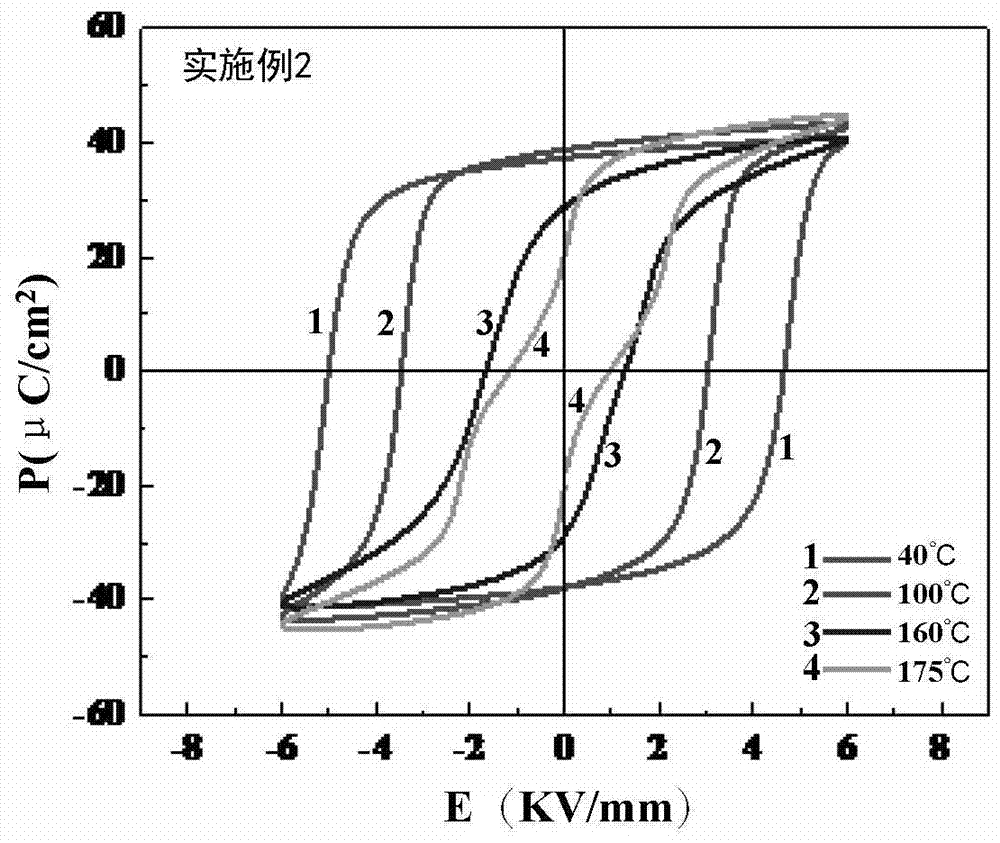

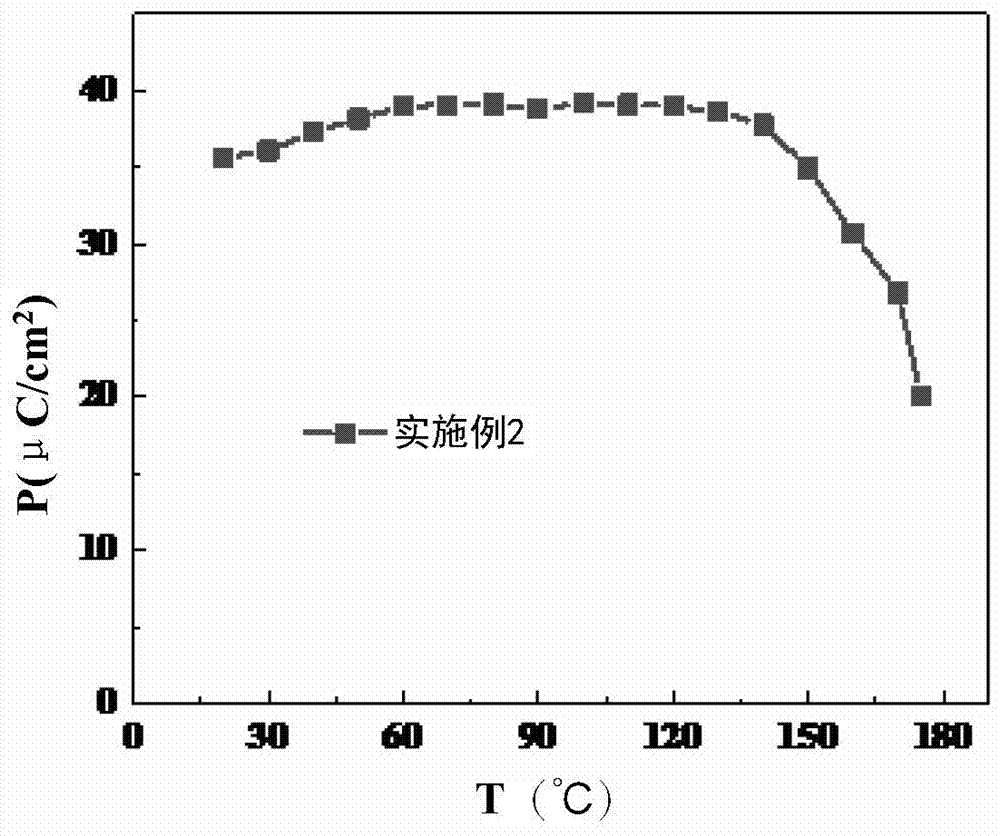

[0050] The ceramic material of the present embodiment is carried out the measurement of electric hysteresis loop under different temperatures, and the results are shown in figure 2 , it can be seen that the hysteresis loop of the material at 160°C exhibits typical ferroelectric properties. As the temperature continues to rise, the FE-AFE phase transition occurs at 175°C, and the hysteresis loop appears a waist phenomenon. image 3 It is the variation of the remanent polarization intensity obtained from the temperature-variable hysteresis loop in Example 2 with temperature. It can be seen that the Pr of the material can reach 30 μC / cm at 160 °...

Embodiment 3

[0052] Embodiment 3: the composition of material is 0.96Bi 0.5 Na 0.5 (Ti 0.980 mn 0.010 )O 3 -0.04BiAlO 3 i.e. x=1.0%

[0053] Repeat the preparation method of Example 1 by the above-mentioned formula.

[0054] The ceramic material of this comparative example is carried out the test of hysteresis loop under room temperature, and the results are shown in Table 1 and Figure 5 . It can be seen that the remnant polarization (P r ) is 38μC / cm 2 .

[0055] The main test results of embodiment 1, embodiment 2, embodiment 3, comparative example 1 have been listed respectively in table 1;

[0056] Table 1 Remanent polarization strength and test conditions of ceramic materials at room temperature

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com