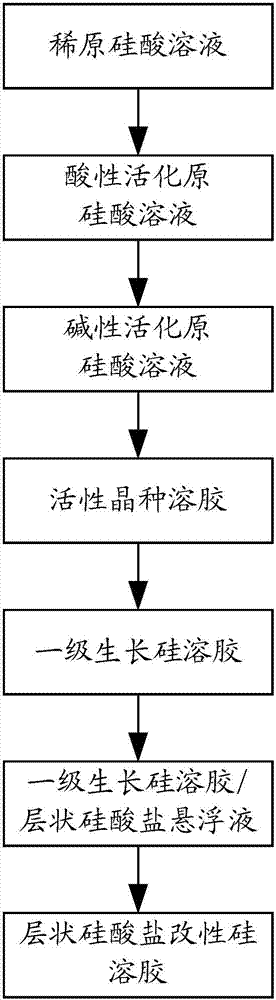

Method for layered silicate modified silica sol

A layered silicate, silica sol technology, applied in the directions of silicate, aluminum silicate, chemical instruments and methods, etc., can solve the problems of high price, large waste liquid, large energy consumption, etc., and achieves low cost, high technology Simple and compatible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Dilute water glass with modulus 3.24 of 3401 from Qingdao Dongyue Soda Soda Factory with deionized water to a solid content of 3%, and pass it through a cation exchange resin to obtain an orthosilicic acid solution. Add 1M sulfuric acid to the solution to adjust its pH to 1. After aging for 72 hours at room temperature, let it pass through the anion exchange resin first, and then immediately pass through the cation exchange resin to obtain an acidic activated orthosilicic acid solution.

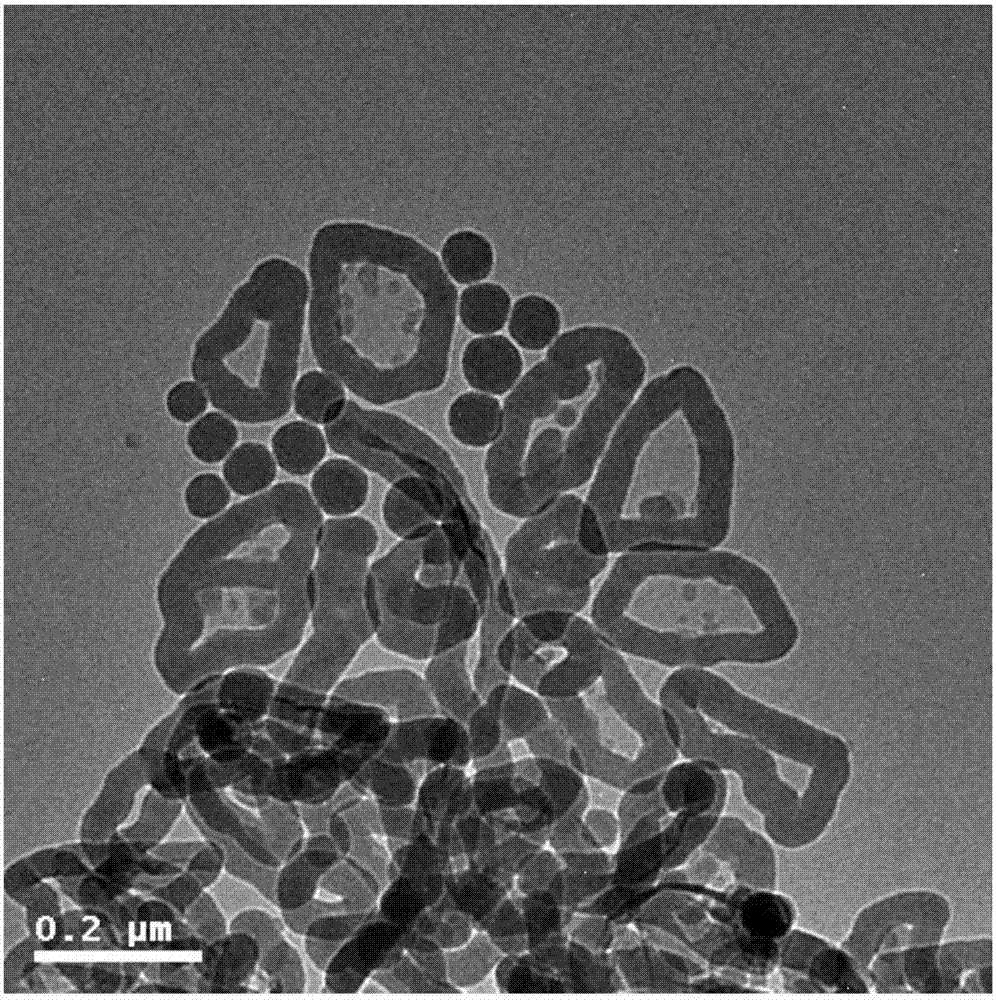

[0048] Add 3% water glass to the acidic activated ortho silicic acid solution to adjust its pH to 10 to obtain an alkaline activated ortho silicic acid solution. Take 250ml of alkaline activated orthosilicic acid solution as the base solution, use the constant liquid level method to control the liquid temperature to 85°C, and add acidic activated orthosilicic acid solution dropwise at a rate of 0.6ml / min, after 5 hours And after adding 200ml of acidic activated orthosilicic acid soluti...

Embodiment 2

[0053] Dilute water glass with modulus 3.24 of 3401 from Qingdao Dongyue Soda Soda Factory with deionized water to a solid content of 5%, and pass it through a cation exchange resin to obtain an orthosilicic acid solution. Add 1M hydrochloric acid to the solution to adjust its pH to 2. After aging at room temperature for 48 hours, let it pass through the anion exchange resin first, and then immediately pass through the cation exchange resin to obtain an acidic activated orthosilicic acid solution.

[0054] Add 1M sodium hydroxide solution to the acidic activated orthosilicic acid solution to adjust its pH to 8. Take 250ml of alkaline activated orthosilicic acid solution as the base solution, use the constant liquid level method to control the liquid temperature to 65°C, and add acidic activated orthosilicic acid solution dropwise at a rate of 0.4ml / min, after 8 hours And after adding 200ml of acidic activated orthosilicic acid solution dropwise, light blue opalescence appeared...

Embodiment 3

[0058] Dilute water glass with modulus 3.24 of 3401 from Qingdao Dongyue Soda Soda Factory with deionized water to a solid content of 4%, and pass it through a cation exchange resin to obtain an orthosilicic acid solution. Add 1M nitric acid to the solution to adjust its pH to 2. After aging at room temperature for 48 hours, let it pass through the anion exchange resin first, and then immediately pass through the cation exchange resin to obtain an acidic activated orthosilicic acid solution.

[0059] Add 1M ammonia solution to the acidic activated orthosilicic acid solution to adjust its pH to 10. Take 250ml of alkaline activated orthosilicic acid solution as the base solution, use the constant liquid level method to control the liquid temperature to 70°C, and add acidic activated orthosilicic acid solution to it at a rate of 0.4ml / min, after 6 hours And after adding 150ml of acidic activated orthosilicic acid solution dropwise, light blue opalescence appeared in the bottom li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com