Vertical column sound absorbing structure for steel structure building

A steel structure and column technology, applied in building structures, buildings, columns, etc., can solve problems such as physical impact, inconvenient communication among factory personnel, and impact on the work of other employees, and achieve the effect of ensuring sound absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

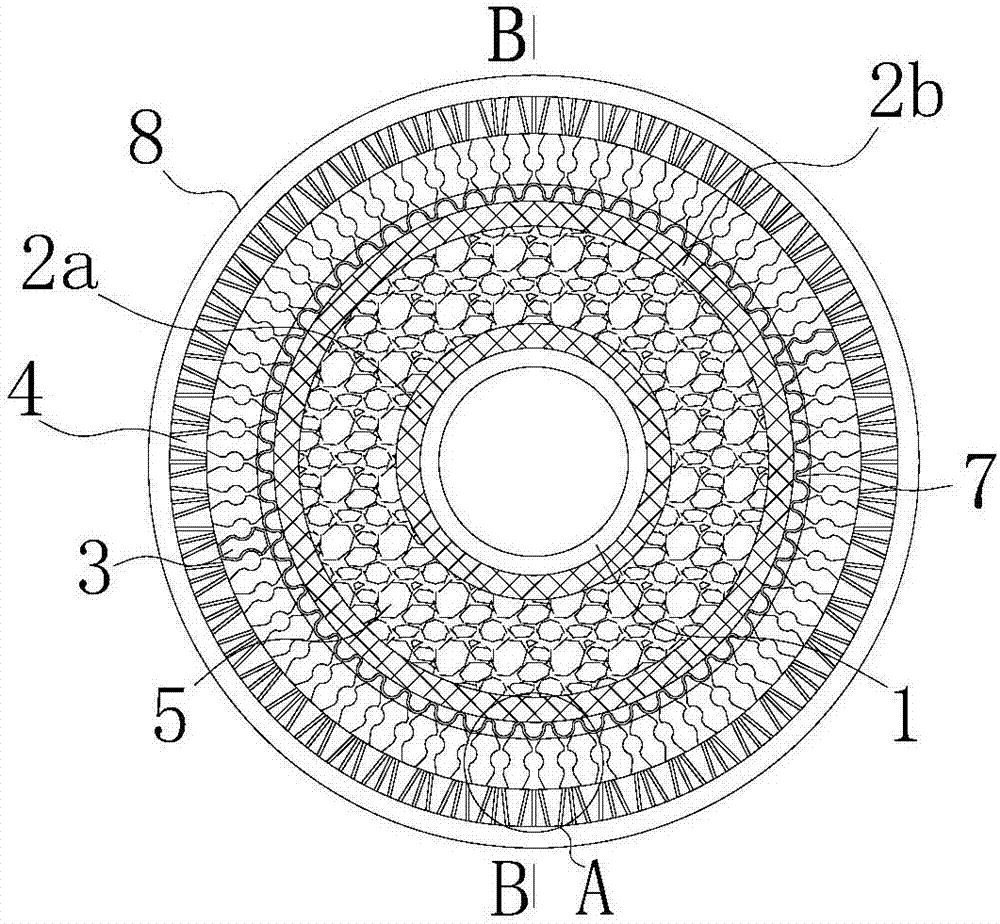

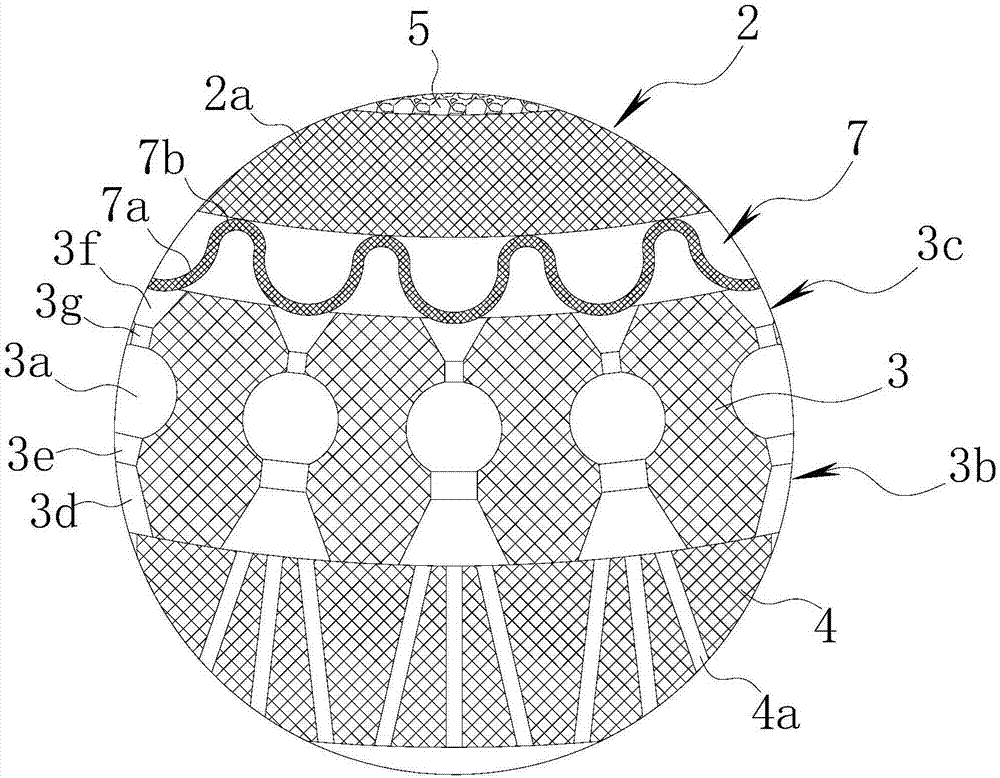

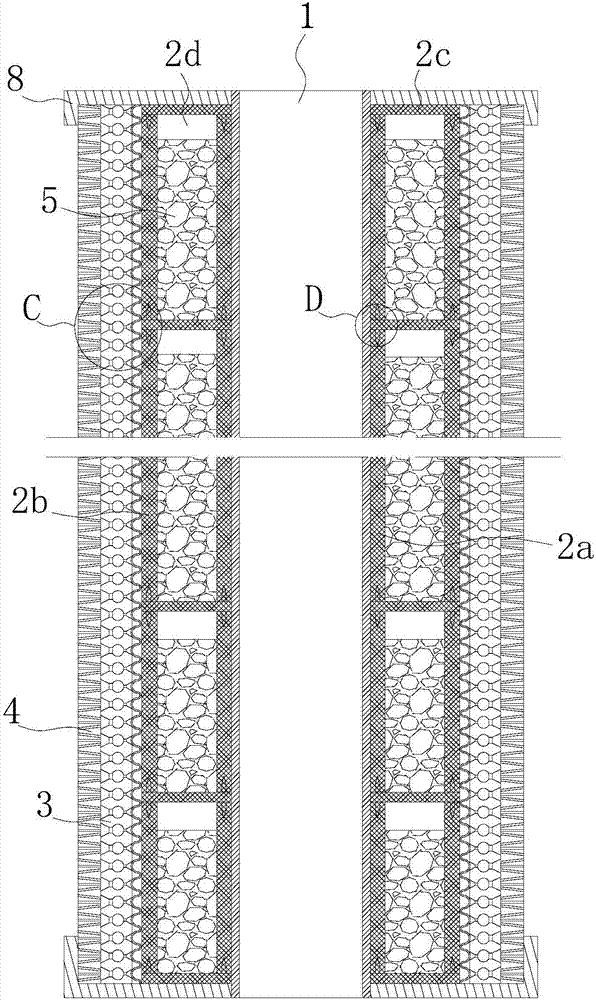

[0024] refer to Figure 1 to Figure 5 As shown, a column sound-absorbing structure for steel structure buildings of the present invention includes a column 1, and the outer wall of the column 1 is sequentially provided with a ring-shaped sound-absorbing unit 2, a first sound-absorbing ring 3 and a second sound-absorbing unit. Ring 4; the ring-shaped sound-absorbing unit 2 mainly includes several inner sound-absorbing rings 2a stacked and wrapped on the outer wall of the column 1 along the axial direction of the column 1, and outer-absorbing single rings 2b corresponding to each inner sound-absorbing ring 2a and arranged at intervals, and setting The sponge ring cover plates 2c at both ends of the matched inner and outer sound-absorbing rings 2a, 2b, the corresponding inner and outer sound-absorbing rings 2a, 2b and the sponge ring cover plates 2c at both ends cooperate to form a ring-shaped sound-absorbing cavity 2d. The sound-absorbing chamber 2d is filled with several sound-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com