Electric soundproof door

A sound-proof door and electric technology, which is applied in the direction of sound-proof doors/windows, AC motor control, electrical components, etc., can solve the problems of electric doors without noise reduction and noise reduction measures, inconvenient manufacturing, transportation, installation, and installation cannot be realized. Achieve the effect of accurate signal control, simple structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

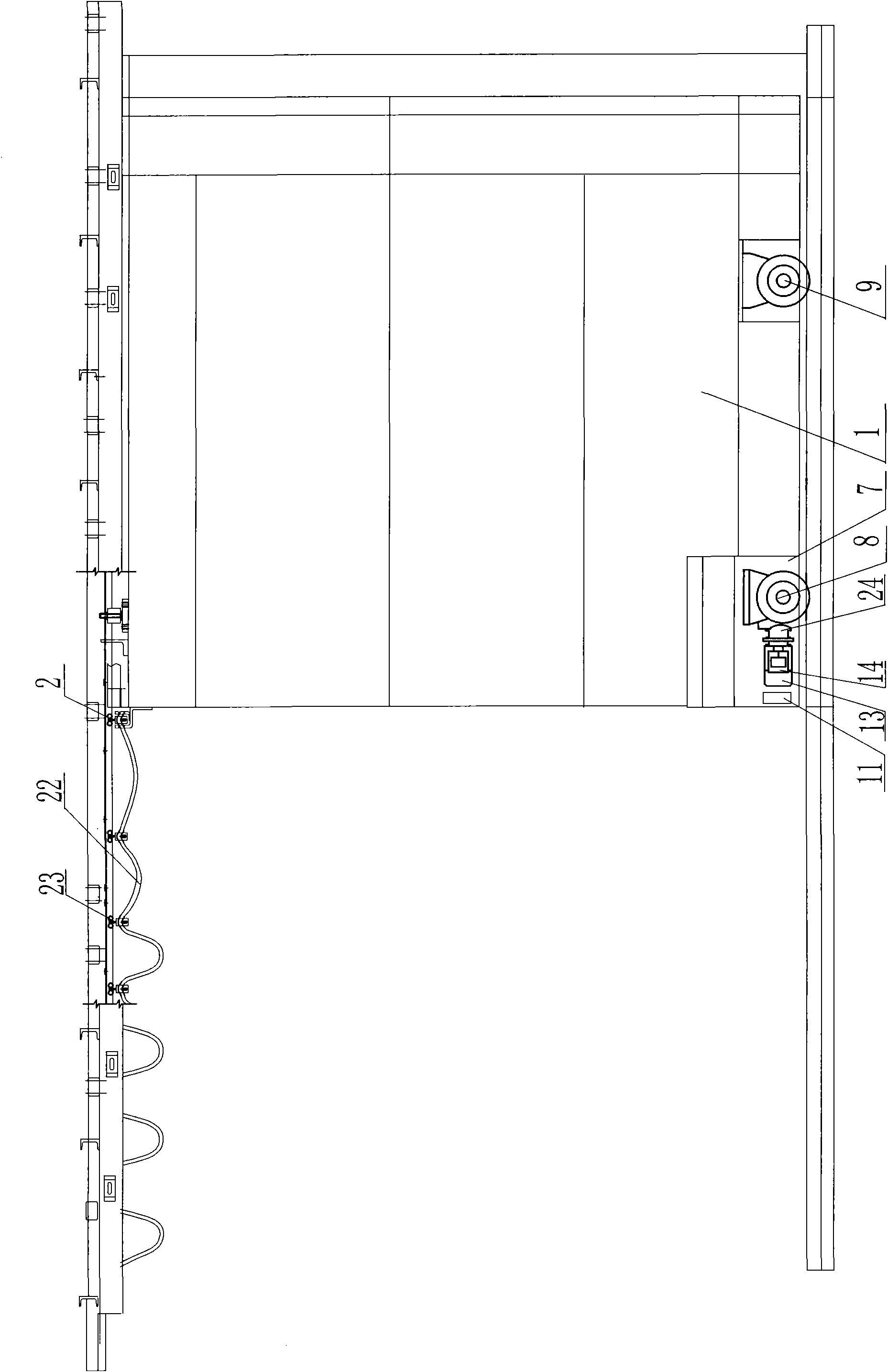

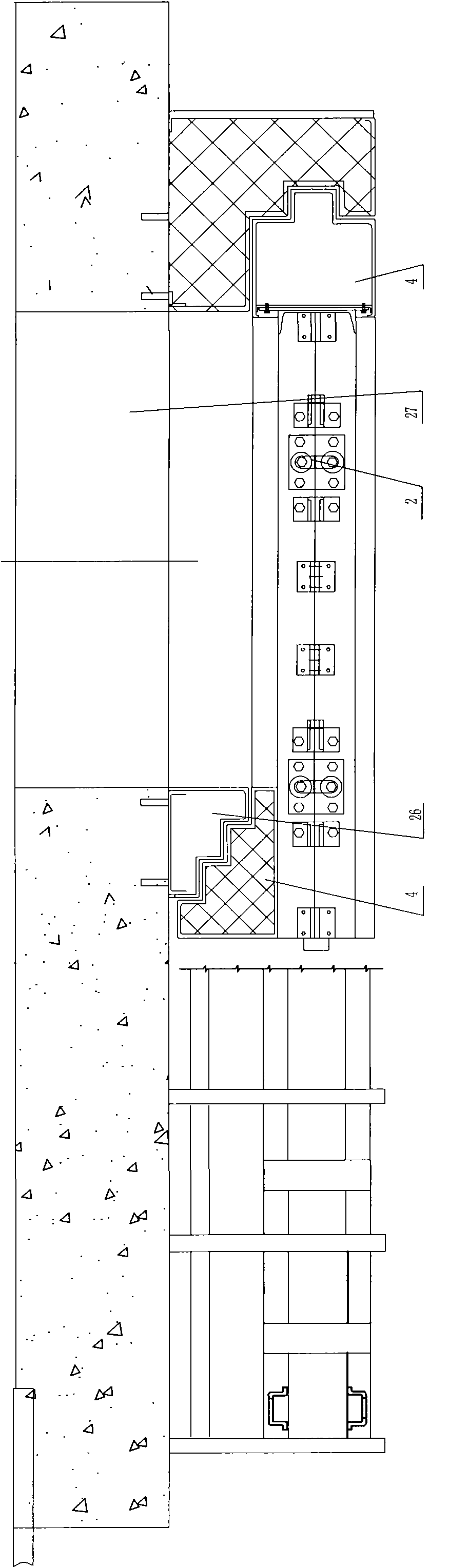

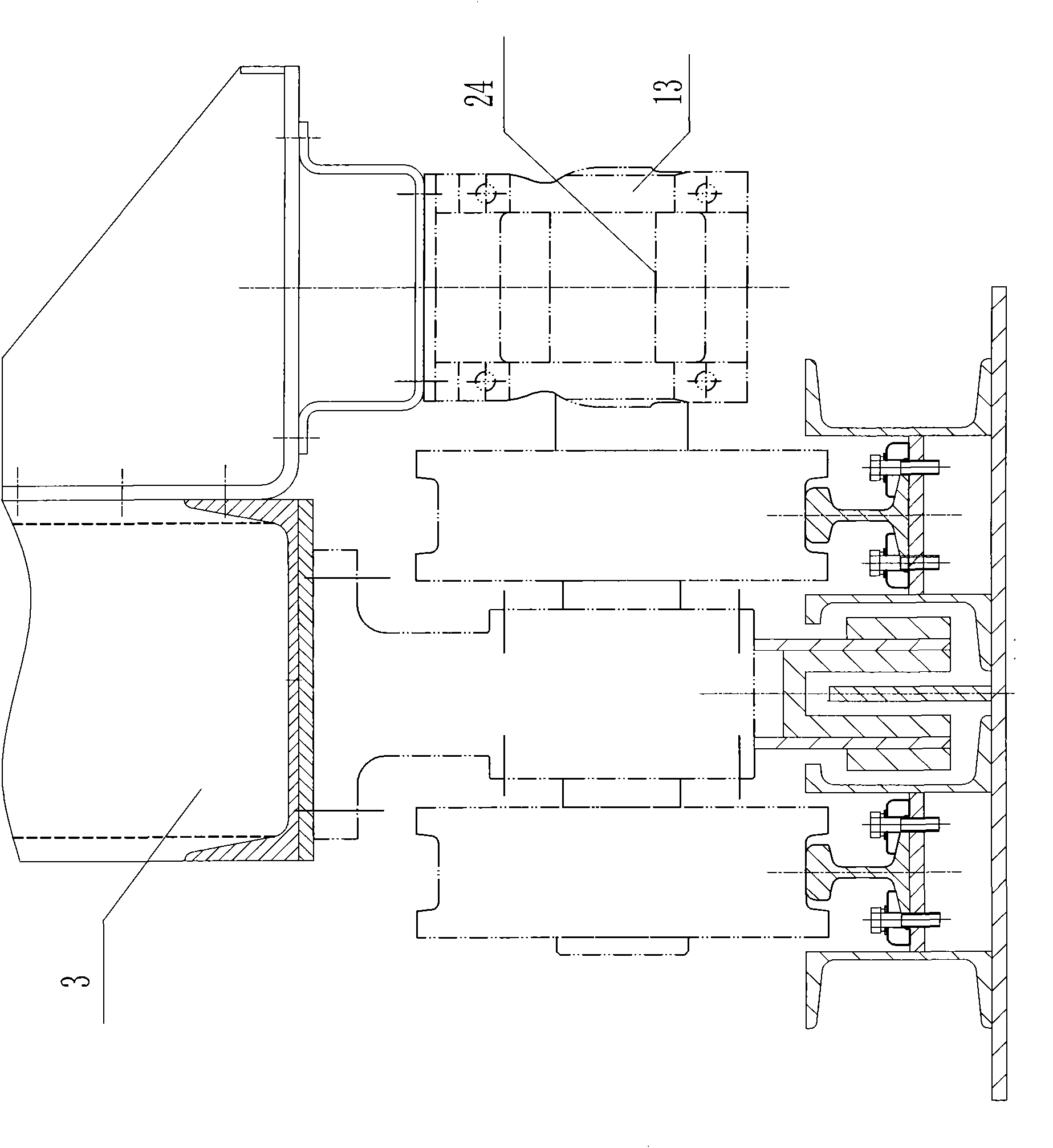

[0036] Electric sound insulation door, its composition includes: a door body 1 with an electrical control system; Except for the top, the other three sides are connected to the door body noise reduction joint 4, the inner side of the inner frame 1 is connected to the inner sound insulation layer 5, and the outer side of the inner frame 3 is connected to the outer sound insulation layer 6, so A motion system 7 is installed below the door body 1 described above.

[0037] The electric sound insulation door, the motion system 7 includes the driving wheel 8, the auxiliary wheel 9 and the ground rail 10, the driving wheel 8 and the auxiliary wheel 9 are connected to the inner frame 3; the ground rail 10 is placed in the reserved pit In, and carry out secondary concrete pouring and fixing.

[0038] The electric sound insulation door, the electrical control system includes a power supply 11, the power supply 11 is connected to the motor 13 through the frequency converter 12, th...

Embodiment 2

[0042] For the electric sound insulation door described in Example 1, the inner frame adopts a split structure, and the frame is mainly welded with 25a channel steel; there are corner ribs at the four corners of the frame, and symmetrical welding is used during welding to balance the stress. After the frame is formed, use M20 bolts to connect the two frames in double rows, and tighten them with double nuts to form a whole, which is the inner frame of the electric door.

Embodiment 3

[0044] For the electric sound insulation door described in Embodiment 1 or 2, the outer sound insulation layer is manufactured in blocks, and the size of each part corresponds to each part of the inner skeleton, and the thickness of the interlayer is 60mm. The outer panel is δ2.0mm cold-rolled plate, with flanging around; a rectangular pipe of 60×40×2.5 is selected to be welded in it as the frame support of the outer sound insulation layer; at the same time, a C-shaped piece can be added to be used as a reinforcement; the position of the support is the same as Corresponding to the inner frame support; the inner panel δ1.5mm cold-rolled plate is welded to the bottom surface to form a seal; the interlayer of the inner and outer panels is filled with absorbent materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com