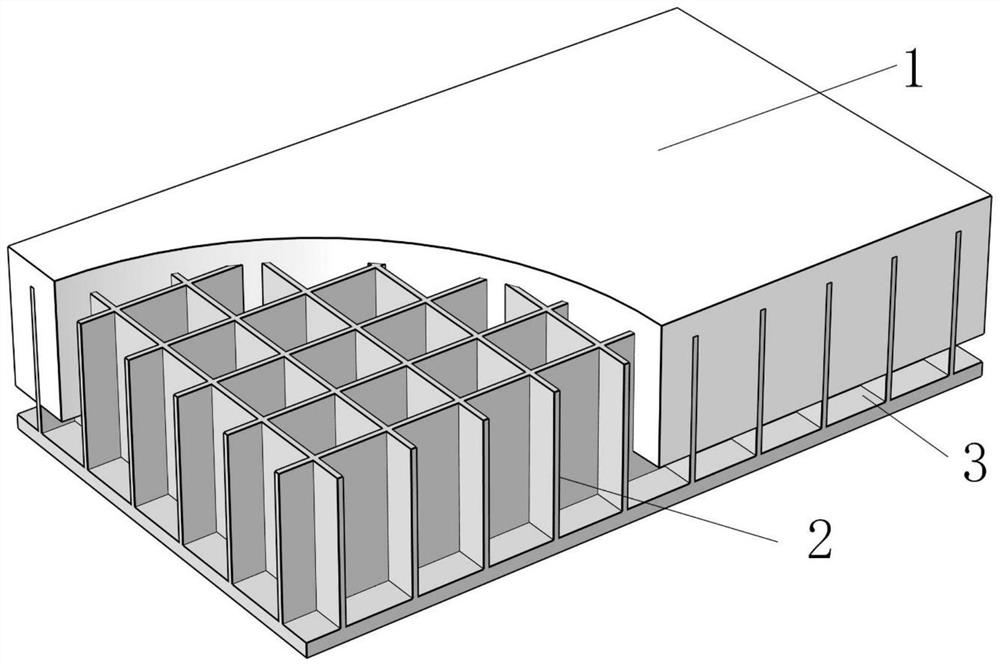

Square honeycomb composite underwater sound absorption structure with built-in air layer

A technology of honeycomb structure and air layer, which is applied in the direction of sound-generating devices, layered products, metal layered products, etc., to achieve the effect of improving sound wave loss ability, water pressure resistance ability and sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

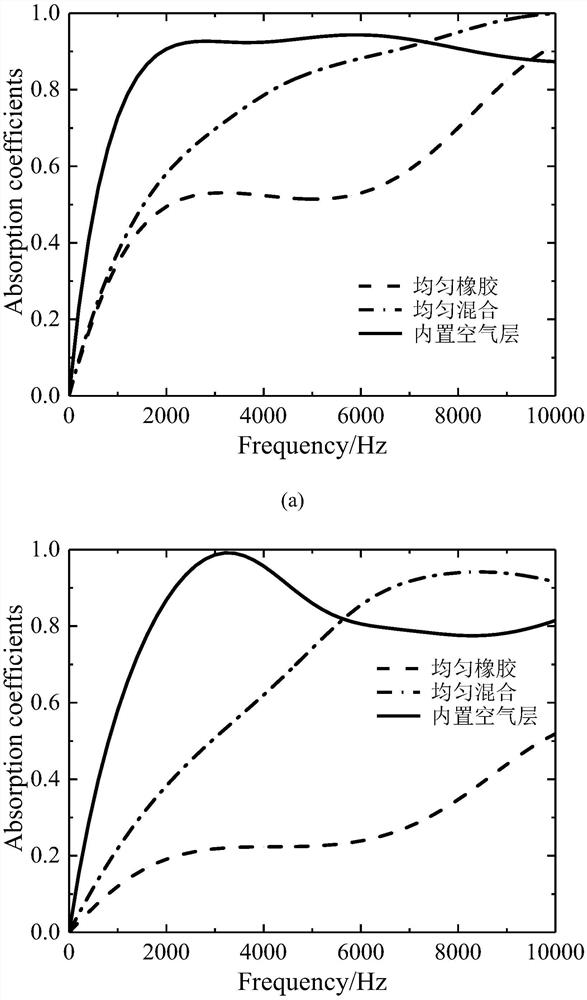

Embodiment 1

[0054] Metal steel: It is characterized by a density of 7850kg / m3, a Young's modulus of 2.05GPa, and a Poisson's ratio of 0.28.

[0055] Viscoelastic material: characterized by a density of 1000kg / m 3 , the longitudinal wave velocity is 1000m / s, the longitudinal wave loss factor is 0.3, the shear wave velocity is 100m / s, and the shear wave loss factor is 0.9.

[0056] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0057] Air: characterized by a density of 1.29kg / m 3 , the speed of sound is 340m / s.

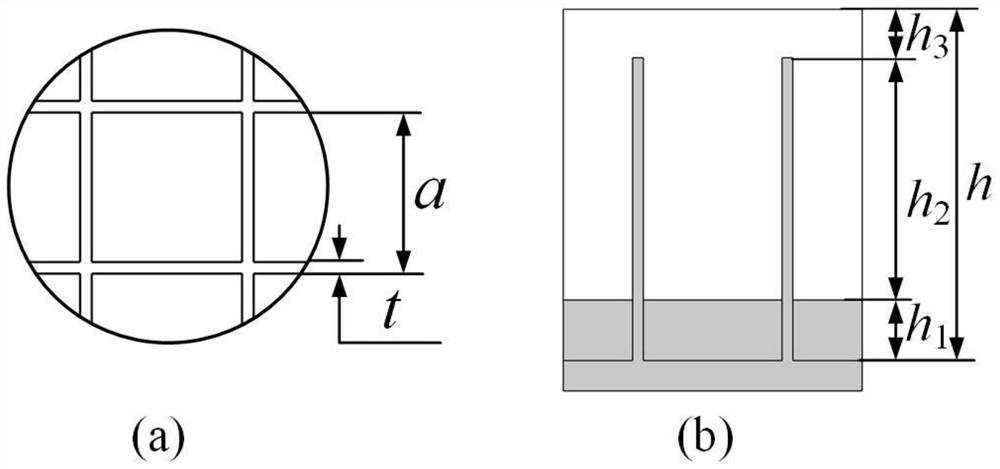

[0058] Embodiment structure size:

[0059] Honeycomb cell size: a=20mm. Metal plate thickness: t=1mm. Air layer thickness: h 1 = 5 mm. Honeycomb rubber mixed layer thickness: h 2 = 40mm. Thickness of upper pure rubber covering layer: h 3 = 5 mm.

Embodiment

[0061] Examples of materials:

[0062] Metal steel: It is characterized by a density of 7850kg / m3, a Young's modulus of 2.05GPa, and a Poisson's ratio of 0.28.

[0063] Viscoelastic material: characterized by a density of 900kg / m 3 , the longitudinal wave velocity is 1200m / s, the longitudinal wave loss factor is 0.09, the shear wave velocity is 100m / s, and the shear wave loss factor is 0.9.

[0064] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0065] Air: characterized by a density of 1.29kg / m 3 , the speed of sound is 340m / s.

[0066] Embodiment structure size:

[0067] Honeycomb cell size: a=25mm. Metal plate thickness: t=1mm. Air layer thickness: h 1 = 6mm. Honeycomb rubber mixed layer thickness: h 2 = 50mm. Thickness of upper pure rubber covering layer: h 3 = 4 mm.

Embodiment 3

[0069] Examples of materials:

[0070] Metal steel: It is characterized by a density of 7850kg / m3, a Young's modulus of 2.05GPa, and a Poisson's ratio of 0.28.

[0071] Viscoelastic material: characterized by a density of 800kg / m 3 , the longitudinal wave velocity is 800m / s, the longitudinal wave loss factor is 0.15, the shear wave velocity is 80m / s, and the shear wave loss factor is 0.8.

[0072] Water: characterized by a density of 1000kg / m 3 , the speed of sound is 1500m / s.

[0073] Air: characterized by a density of 1.29kg / m 3 , the speed of sound is 340m / s.

[0074] Embodiment structure size:

[0075] Honeycomb cell size: a=20mm. Metal plate thickness: t=1mm. Air layer thickness: h 1 = 4 mm. Honeycomb rubber mixed layer thickness: h 2 = 35mm. Thickness of upper pure rubber covering layer: h 3 = 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com