Environment-friendly nitro pencil head lacquer and preparation method thereof

A nitro and pencil technology, applied in the field of nitro lacquer, can solve the problems of high and low viscosity of nitro lacquer, high viscosity of finished products, non-compliance, etc., and achieve the effects of alleviating work intensity, improving production environment, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

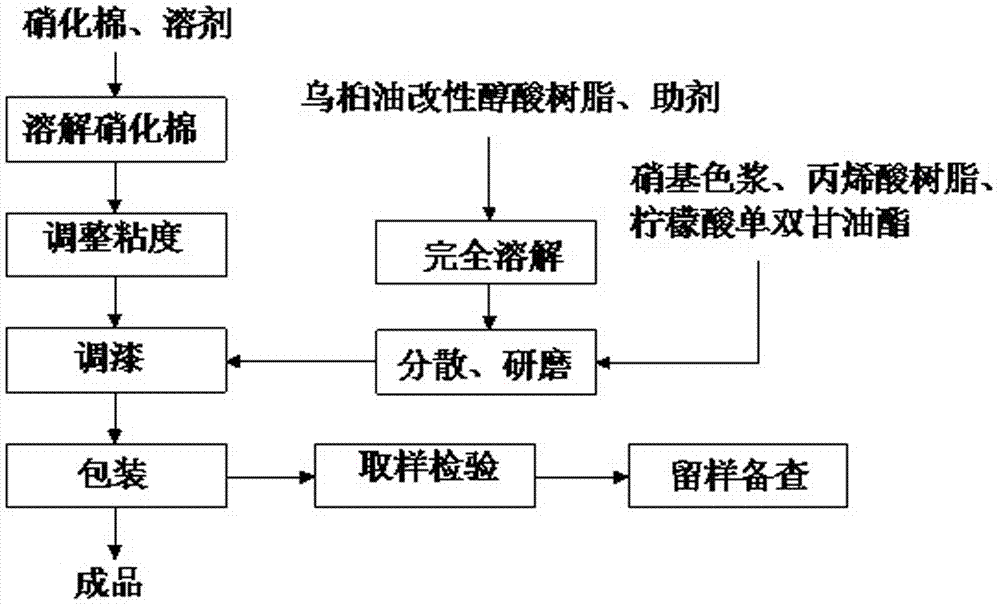

Method used

Image

Examples

preparation example Construction

[0066] Preparation of tallow oil modified alkyd resin

[0067] Put 250 kg of tallow tree oil and 100 kg of glycerin into the reactor, raise the temperature to 120°C, add 1.5 kg of lithium hydroxide under stirring, then raise the temperature to 220°C, stir for 1 hour, add 200 kg of phthalic anhydride, 100 kg of butyl acetate kg, 50 kg of acetone. Reflux for 3 hours, then lower to 25°C for later use.

[0068] The technical indicators achieved are as follows:

[0069] Appearance: clear and transparent, without mechanical impurities;

[0070] Acid value: ≤15 mg LiOH / g;

[0071] Color: ≤10 (iron-cobalt method);

[0072]Viscosity: 8-10 seconds (25°C);

[0073] Solid content: 60±2%;

[0074] Fineness: ≤10 microns.

preparation Embodiment 1

[0076] This preparation method comprises the steps:

[0077] (1) Take 10 kg of the prepared tallow tree oil modified alkyd resin, 1 kg of vinyl acetate, 0.5 kg of methyl acrylate, mix, stir slowly until completely dissolved, then add 15 kg of nitro colorant, 2 kg of acrylic resin 1 kg of citric acid monoglycerides (respectively 0.5 kg of monoester and 0.5 kg of diester), disperse at high speed in a high-speed mixer for 30 minutes, transfer to a grinder and grind for 30 minutes, and use a scraper fineness meter to detect the fineness of the color paste When the density reaches ≤10μm, add it to the paint mixing tank and set aside.

[0078] (2) Dissolve 60 kg of nitrocellulose and 3 kg of ethyl acetate in a dissolving tank. After adjusting the viscosity, add it to the paint mixing tank in step (1), mix it with the mixture in the paint mixing tank, discharge the slurry, and adjust the color , detection, canning.

preparation Embodiment 2

[0080] This preparation method comprises the steps:

[0081] (1) Take 20 kg of the prepared tallow tree oil modified alkyd resin, 1 kg of vinyl acetate, 2 kg of n-butyl methacrylate, mix, stir slowly until completely dissolved, then add 20 kg of nitro colorant, acrylic acid 5 kg of resin, 4.5 kg of mono- and di-glycerides of citric acid (respectively 3 kg of mono-ester and 1.5 kg of di-ester), disperse in a high-speed mixer for 60 minutes at high speed, transfer to a grinder and grind for 60 minutes, and use a scraper fineness meter to detect The fineness of the color paste reaches ≤10μm, and it is added into the paint mixing tank.

[0082] (2) Dissolve 70 kg of nitrocellulose, 3 kg of butyl acetate, and 4 kg of cyclohexanone in a dissolving tank. After adjusting the viscosity, add it to the paint mixing tank in step (1) and mix it with the mixture in the paint mixing tank , pulping, toning, testing, canning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com