Treatment method and device of waste emulsion water

A treatment method and technology of a treatment device, applied in the field of water treatment, can solve problems such as low filtration flux, and achieve the effect of improving filtration flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

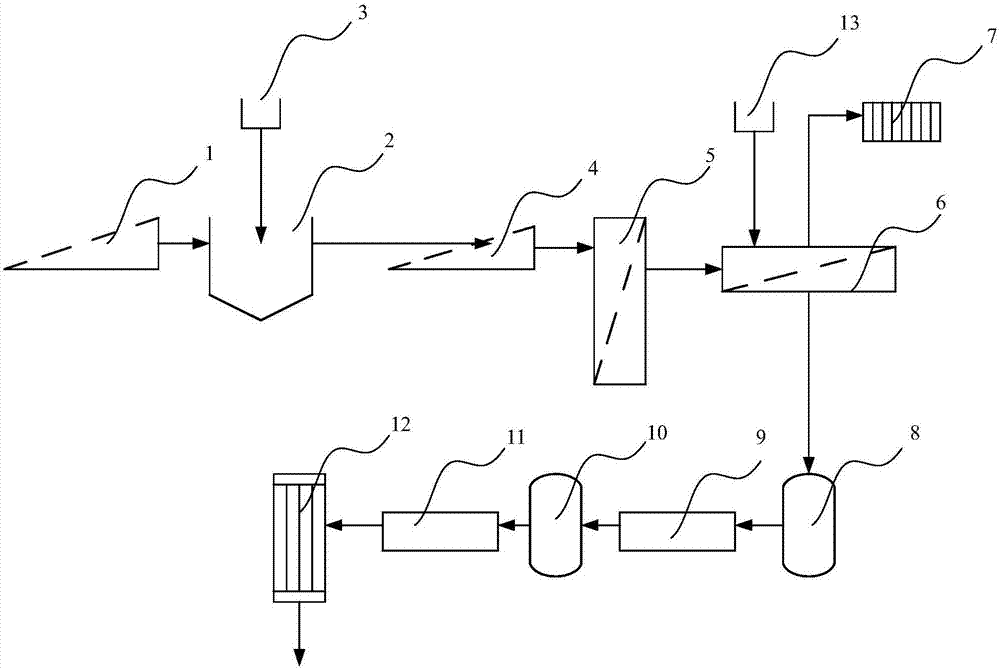

[0089] The first step is to carry out inclined plate oil separation treatment on the emulsion wastewater to remove the slick oil;

[0090] In the second step, the waste water obtained in the first step is flocculated. The addition of the flocculant is 0.1wt% of the waste water weight. The flocculant is composed of polyaluminum calcium chloride, ferric chloride, polyacrylamide, citric acid, polymer Ferric chloride and bentonite are mixed, and the weight ratio is 1:0.8:1:0.1:0.1:1;

[0091] In the third step, the wastewater obtained in the second step is subjected to inclined plate sedimentation treatment to remove sediment;

[0092] In the 4th step, the waste water obtained in the 3rd step is filtered by a quartz sand filter to remove impurities of large particles;

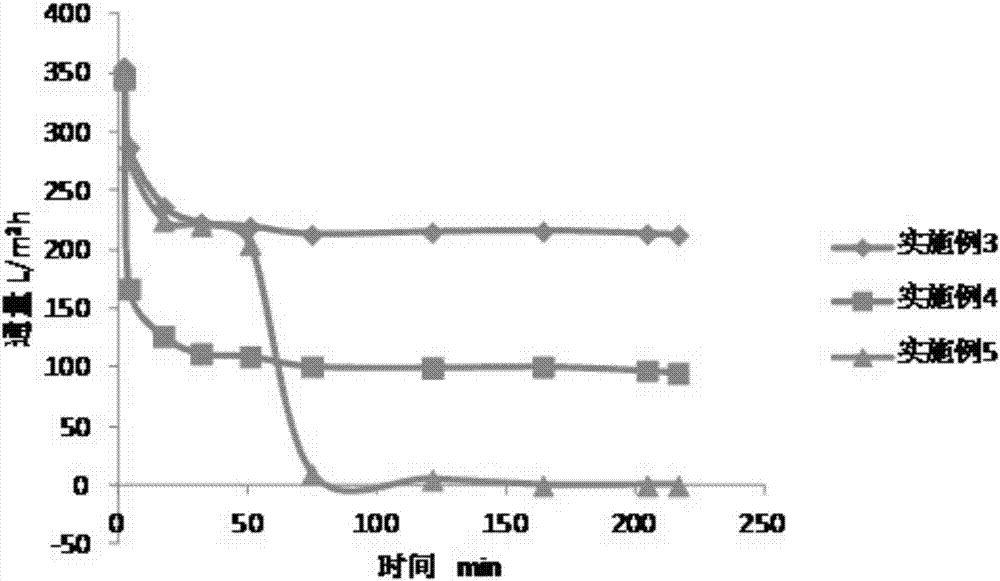

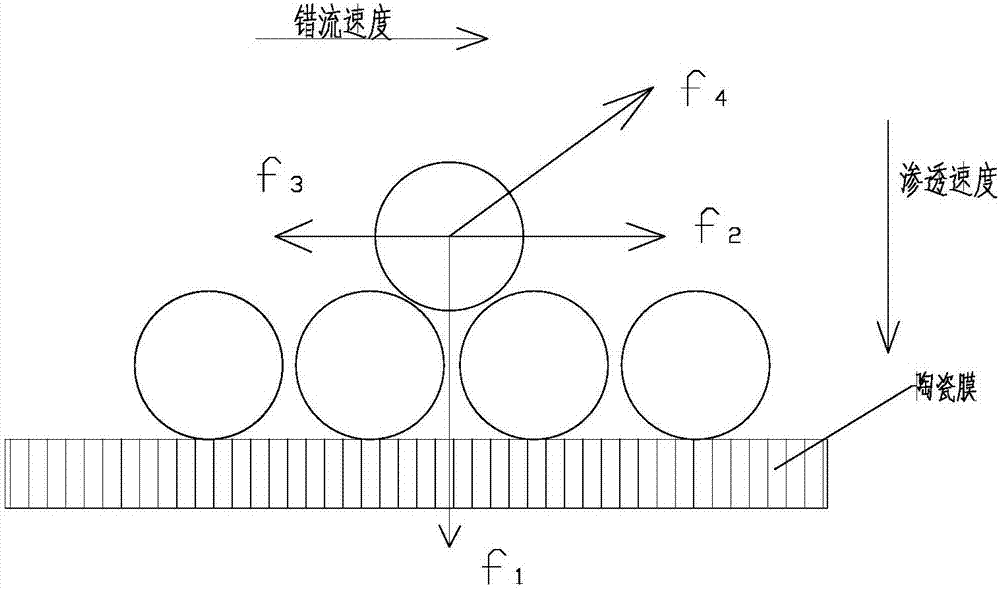

[0093] In the 5th step, the waste water obtained in the 4th step is filtered by a tubular ceramic membrane filter, and the structure of the ceramic membrane filter is as follows Figure 5-7 As shown, the average ...

Embodiment 2

[0097] The first step is to carry out inclined plate oil separation treatment on the emulsion wastewater to remove the slick oil;

[0098] In the second step, the wastewater obtained in the first step is flocculated. The amount of flocculant added is 0.1 to 0.5 wt% of the wastewater weight. , Polymerized ferric chloride, bentonite mixed, the weight ratio is 1: 0.9: 2: 2: 0.4: 4;

[0099] In the third step, the wastewater obtained in the second step is subjected to inclined plate sedimentation treatment to remove sediment;

[0100] In the 4th step, the waste water obtained in the 3rd step is filtered by a quartz sand filter to remove impurities of large particles;

[0101] In the 5th step, the waste water obtained in the 4th step is filtered by a tubular ceramic membrane filter, and the structure of the ceramic membrane filter is as follows Figure 5-7 As shown, the average pore size range of the tubular ceramic membrane filter is 500μm, the membrane surface flow velocity dur...

Embodiment 3

[0105] The first step is to carry out inclined plate oil separation treatment on the emulsion wastewater to remove the slick oil;

[0106] In the second step, the wastewater obtained in the first step is flocculated. The amount of flocculant added is 0.1 to 0.5 wt% of the wastewater weight. , Polymerized ferric chloride, bentonite mixed, the weight ratio is 1:0.85:1.5:0.5:0.2:2;

[0107] In the third step, the wastewater obtained in the second step is subjected to inclined plate sedimentation treatment to remove sediment;

[0108] In the 4th step, the waste water obtained in the 3rd step is filtered by a quartz sand filter to remove impurities of large particles;

[0109] In the 5th step, the waste water obtained in the 4th step is filtered by a tubular ceramic membrane filter, and the structure of the ceramic membrane filter is as follows Figure 5-7 As shown, the average pore size range of the tubular ceramic membrane filter is 200 μm, the membrane surface flow rate during...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com