Resourceful treatment method for coal gasification wastewater

A technology for coal gasification wastewater and treatment methods, applied in chemical instruments and methods, extraction water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing the processing load of biochemical systems, improving COD indicators, and extractant loss High efficiency and other problems, to achieve the effects of effective recycling, efficient recycling, and control of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

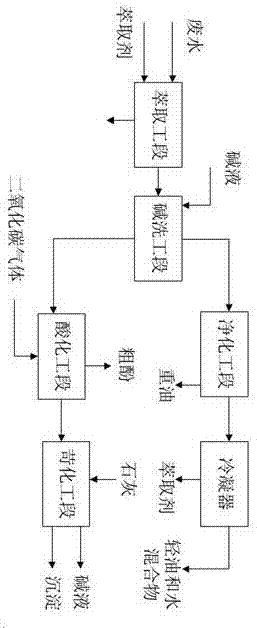

Method used

Image

Examples

Embodiment 1

[0023] The coal gasification wastewater to be treated is the wastewater after deacidification, deamination and pre-oil removal. The main indicators are: COD: 10000mg / L; oil: 100mg / L; phenol: 2000mg / L; pH value: 7.8.

[0024] The actual wastewater treatment process is as follows: the extraction oil-water ratio is 1:10, the cross-flow contact time is about 30 minutes, the temperature at the top of the extraction section is 30°C, and the dephenolized wastewater is discharged from the bottom after the treatment reaches the standard; the phenol-rich organic phase uses 10% sodium hydroxide The solution is used as an alkali washing solution, and the sodium phenate produced enters the acidification section, and the acidification section passes into the deacidification gas generated by the wastewater deacidification treatment section, the main component is carbon dioxide; the molar ratio of carbon dioxide to sodium phenate is 1.5:1, and the reaction temperature is 20 °C , after the sodi...

Embodiment 2

[0028] The coal gasification wastewater to be treated is the wastewater after deacidification, deamination and pre-oil removal. The main indicators are: COD: 29000mg / L; oil: 350mg / L; phenol: 6500mg / L; pH value: 8.

[0029] The actual wastewater treatment process is as follows: the oil-water ratio of the extractant is 1:2, the cross-flow contact time is about 30min, the temperature at the top of the extraction section is 80°C, and the treated dephenolized wastewater is discharged from the bottom; the phenol-rich organic phase is oxidized with 15% hydrogen The sodium solution is used as the alkaline washing solution, and the sodium phenate produced enters the acidification section, and the acidification section passes into the deacidification gas generated by the wastewater deacidification treatment section, the main component of which is carbon dioxide. The molar ratio of carbon dioxide to sodium phenate is 1.5:1, and the reaction temperature is 40°C. After the complete reaction...

Embodiment 3

[0033] The coal gasification wastewater to be treated is the wastewater after deacidification, deamination and pre-oil removal. The main indicators are: COD: 40000mg / L; oil: 500mg / L; phenol: 10000mg / L; pH value: 7.8.

[0034] The actual process of wastewater treatment is as follows: The ratio of oil to water in the extractant is 1:1. The cross-flow contact time is about 30 minutes, the temperature at the top of the extraction section is 45°C, and the dephenolized wastewater that has reached the standard is discharged from the bottom; 20% sodium hydroxide solution is used as the alkaline washing solution for the phenol-rich organic phase, and the sodium phenate produced enters the acidification section. The deacidification gas produced by the acidification section is fed into the wastewater deacidification treatment section, and its main component is carbon dioxide. The molar ratio of carbon dioxide to sodium phenate is 2:1, and the reaction temperature is 50°C. After the compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com