Water purification agent for aquaculture ponds and preparation method of water purification agent

An aquaculture and purifying agent technology, applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problem of easily destroying the pond biological community structure, unfavorable growth of pond cultured organisms, and unsatisfactory effects. and other problems, to achieve the effect of improving the pond community structure, conducive to healthy growth and improving immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

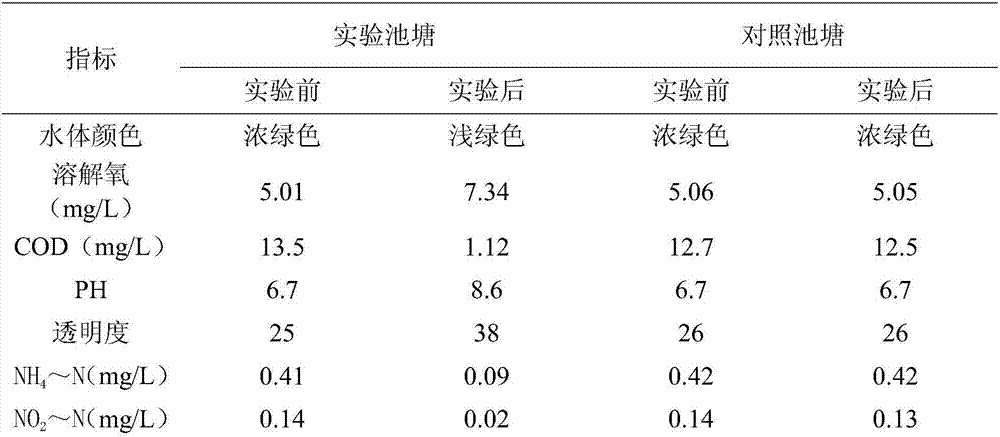

Embodiment 1

[0030] A preparation method of water quality purifying agent for aquaculture pond, comprising the following steps:

[0031] (1) Mix potato leaves, dandelion, and glutinous rice flour in a weight ratio of 5:3:1, add water of the same quality as the mixture to the mixture, and put it in a constant temperature oscillating water bath under the conditions of 70-80°C and 200r / min Shock treatment for 100 minutes;

[0032] (2) Purslane and Baiwei are mixed according to a weight ratio of 3:1, put into a grinder, and grind for 25min in a grinder with a rotating speed of 4000 rpm;

[0033] (3) Attapulgite and fly ash are mixed according to a weight ratio of 2:1, put into a grinder, and grind for 30min in a grinder with a rotating speed of 4000 rpm;

[0034] (4) Grinding and pulverizing the Chinese toon skin, adding clear water with a weight of 8 times the mass of the Chinese toon skin, decocting the juice with slow fire and concentrating until the juice amount is 1 / 4 of the initial clea...

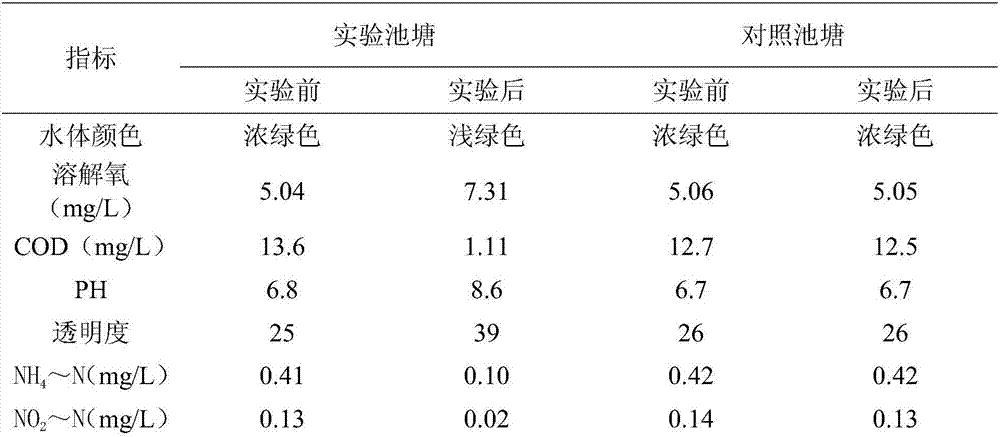

Embodiment 2

[0039] A preparation method of water quality purifying agent for aquaculture pond, comprising the following steps:

[0040] (1) Mix potato leaves, dandelion, and glutinous rice flour in a weight ratio of 6:3:1, add water of equal quality to the mixture, and put it in a constant temperature oscillating water bath under the conditions of 70-80°C and 150r / min Shock treatment for 100 minutes;

[0041] (2) Purslane and Baiwei are mixed according to a weight ratio of 3:1, put into a grinder, and grind for 25min in a grinder with a rotating speed of 4000 rpm;

[0042] (3) Attapulgite and fly ash are mixed according to a weight ratio of 2:1, put into a grinder, and grind for 30min in a grinder with a rotating speed of 5000 rpm;

[0043] (4) Grinding and pulverizing the Chinese toon skin, adding clear water with a weight of 8 times the mass of the Chinese toon skin, decocting the juice with slow fire and concentrating until the juice amount is 1 / 4 of the initial clear water amount;

...

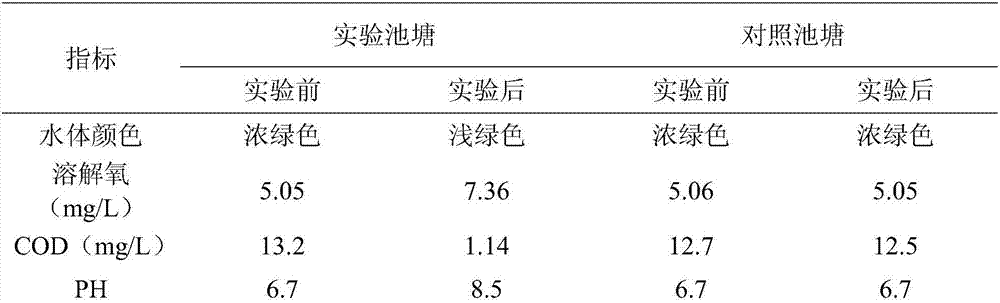

Embodiment 3

[0048] A preparation method of water quality purifying agent for aquaculture pond, comprising the following steps:

[0049] (1) Mix potato leaves, dandelion, and glutinous rice flour in a weight ratio of 6:4:1, add water of equal quality to the mixture, and put it in a constant temperature oscillating water bath under the conditions of 70-80°C and 100r / min Shock treatment for 100 minutes;

[0050] (2) Purslane and Baiwei are mixed according to a weight ratio of 3:1, put into a grinder, and grind for 20 minutes in a grinder with a rotating speed of 5000 rpm;

[0051] (3) Attapulgite and fly ash are mixed according to a weight ratio of 2:1, put into a grinder, and grind for 30min in a grinder with a rotating speed of 4000 rpm;

[0052] (4) Grinding and pulverizing the Chinese toon skin, adding clear water with a weight of 8 times the mass of the Chinese toon skin, decocting the juice with slow fire and concentrating until the juice amount is 1 / 4 of the initial clear water amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com