High-strength large-size block carbon aerogel and preparation method and application thereof

A carbon aerogel and large-scale technology, which is applied in the field of high-strength and large-size block carbon aerogel and its preparation, can solve the problems of not improving the network structure of the organic gel and the limited effect of strength improvement, so as to inhibit the growth of cracks. , good molding ability, the effect of improving the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

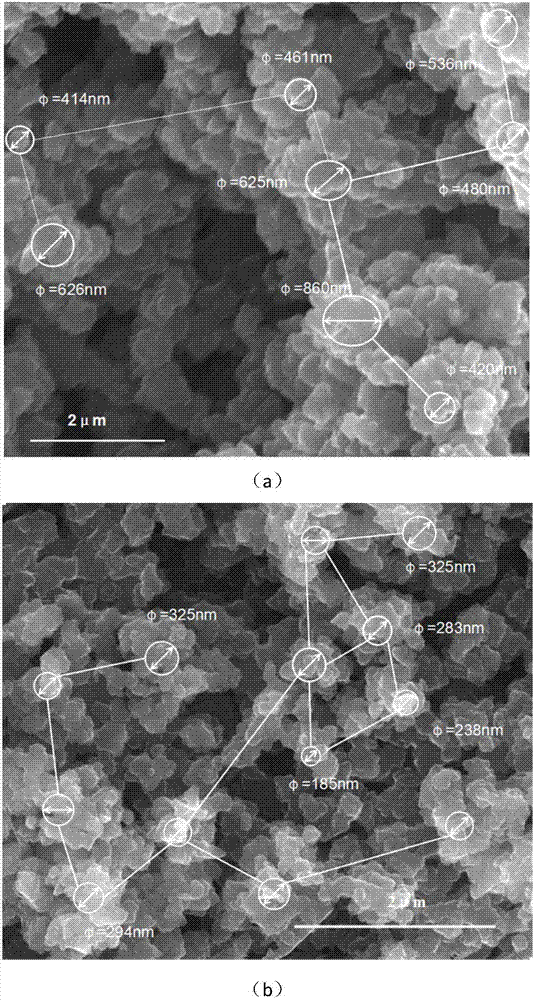

[0029] Mix resorcinol, 37wt.% formaldehyde solution, deionized water, and anhydrous sodium carbonate at a mass ratio of 2637:2637:5776:1 and heat in a water bath. When the temperature of the water bath is adjusted to 15°C, the holding time 30 hours; when the temperature of the water bath is adjusted to 45°C, the holding time is 20 hours; when the temperature of the water bath is adjusted to 65°C, the holding time is 20 hours; when the temperature of the water bath is adjusted to 95°C, the holding time is 10 hours to obtain a wet gel. The obtained wet gel was soaked in absolute ethanol 10 times the volume of the gel at 50°C for 24 hours, and this step was repeated 4 times. Afterwards, the wet gel was dried at 50 °C for 7 days in an atmospheric drying oven. The dried gel was placed in a carbonization furnace under the protection of argon, and the temperature was raised from room temperature to 900°C at a heating rate of 5°C / min. After two hours of heat preservation, it was coole...

Embodiment 2

[0033] Mix resorcinol, 37wt.% formaldehyde solution, deionized water, and anhydrous sodium carbonate at a mass ratio of 1030:1530:2880:1 to obtain a mixed solution and heat it in a water bath, and adjust the temperature of the water bath to 30°C When the temperature of the water bath is adjusted to 50°C, the holding time is 50 hours; when the temperature of the water bath is adjusted to 75°C, the holding time is 30 hours; when the temperature of the water bath is adjusted to 95°C, the holding time is 10 hours. wet gel. The obtained wet gel was soaked in absolute ethanol 10 times the volume of the gel at 50°C for 24 hours, and this step was repeated 4 times. Afterwards, the obtained wet gel was dried in an atmospheric drying oven at 50°C for 7 days. The dried gel was placed in a carbonization furnace under the protection of argon, and the temperature was raised from room temperature to 900°C at a heating rate of 5°C / min. After two hours of heat preservation, it was cooled with...

Embodiment 3

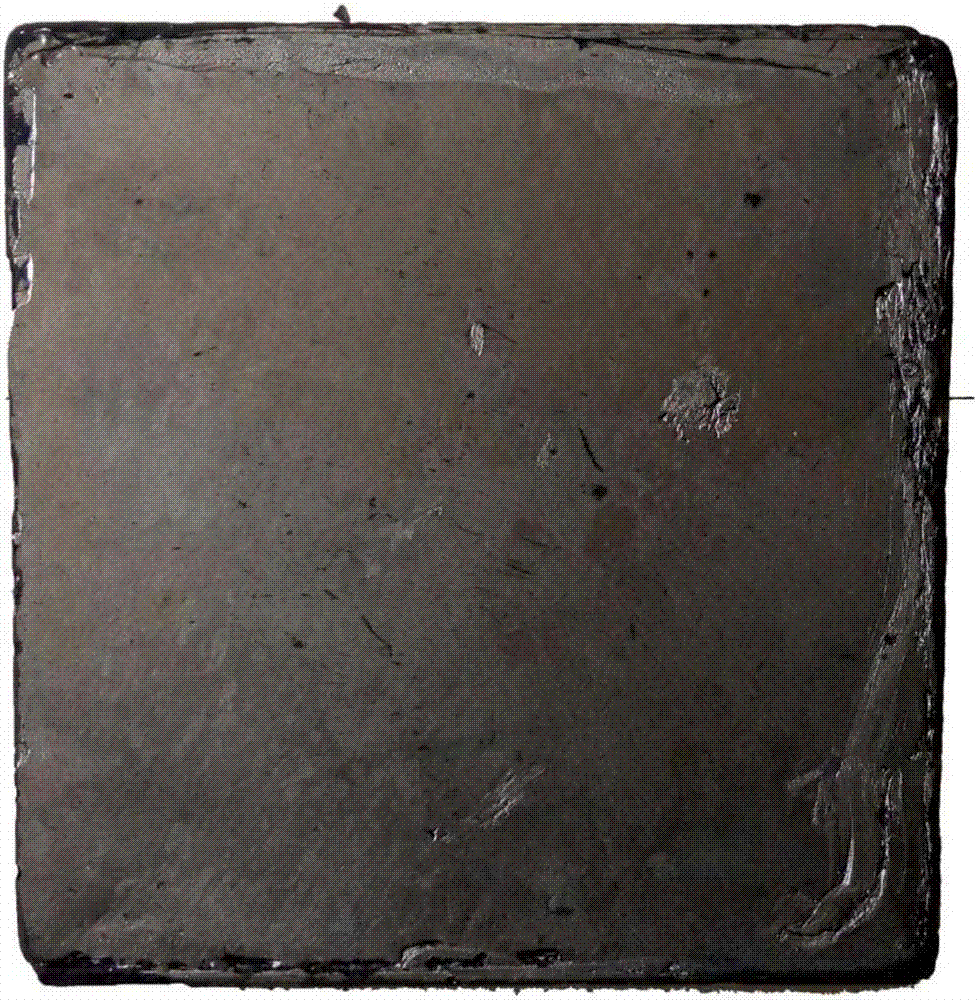

[0036] Mix resorcinol, 37wt.% formaldehyde solution, deionized water, and anhydrous sodium carbonate in a mass ratio of 520:760:1440:1 and heat in a water bath: when the temperature of the water bath is adjusted to 45°C, keep warm The time is 80 hours; when the temperature of the water bath is adjusted to 65°C, the holding time is 70 hours; when the temperature of the water bath is adjusted to 95°C, the holding time is 50 hours to obtain a wet gel. Soak the obtained wet gel in absolute ethanol 10 times the volume of the gel at 50° C. for 24 hours, and repeat this step 4 times. Afterwards, the obtained wet gel was dried in an atmospheric drying oven at 50°C for 7 days. The dried gel was placed in a carbonization furnace under the protection of argon, and the temperature was raised from room temperature to 900°C at a heating rate of 5°C / min. After two hours of heat preservation, it was cooled with the furnace to obtain a high-strength carbon aerogel.

[0037] The carbon airgel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com