Plate connecting structure for prestressed concrete member tensioning mechanism

A tensioning mechanism and plate connection technology, applied in the plate field, can solve problems such as leakage of tensioning nut, damage to tensioning nut, damage to the end face of prestressed concrete members, etc., and achieve the effect of preventing damage and avoiding contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

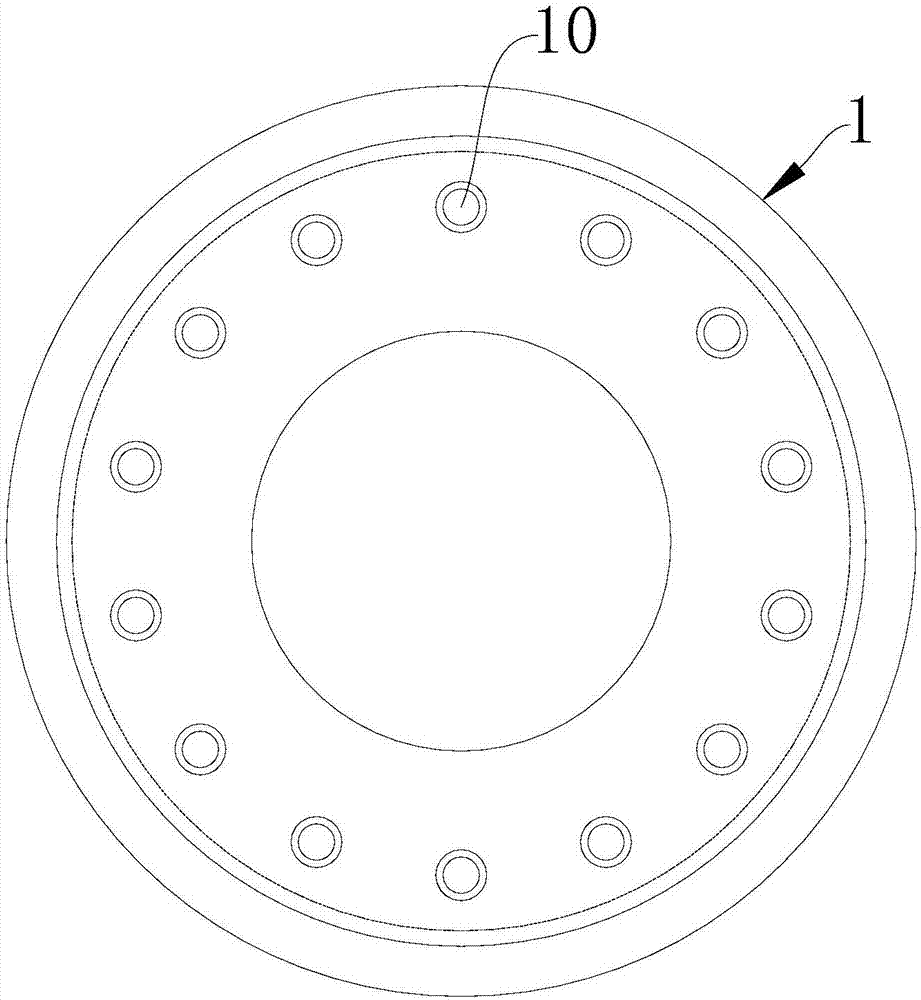

[0039] Such as Figure 2 to Figure 5 As shown, the abutting portion 4 is integrally formed with the connecting bolt 2 .

[0040] Specifically, such as figure 2 with image 3 As shown, the connecting bolt 2 includes an insertion part 20 and a connection part 21 located at the top of the insertion part 20 and is suitable for fixed connection with the tension nut 3; the outer diameter of the end surface of the connection part 21 is consistent with the inner cavity outer diameter of the tension nut 3 The outer diameter of the end surface of the inserting portion 20 is larger than that of the connecting portion 21 , and when the connecting bolt 2 is inserted into the through hole 10 , the inserting portion 20 partially protrudes from the end surface of the plate body 1 to form the contact portion 4 .

Embodiment 2

[0042] Such as Figure 4 with Figure 5 As shown, the outer diameter of the connecting bolt 2 is consistent with the outer diameter of the inner cavity of the tension nut 3, and the outer periphery of one end close to the tension nut 3 is provided with a protruding portion 40 extending radially outward, and the protruding portion 40 is consistent with the connecting bolt 2. The abutting portion 4 is integrally formed, and the opposite end is provided with a locking piece 5 suitable for locking the connecting bolt 2 .

Embodiment 3

[0044] Such as Image 6 with Figure 8As shown, the outer diameter of the connecting bolt 2 is consistent with the outer diameter of the inner cavity of the tension nut 3, which is inserted into the through hole 10, and the pad protruding from the end surface of the plate body 1 is sleeved and connected to the end surface 11 of the plate body 1. The sheet 6 and the washer 6 extend radially outward to form the contact portion 4 .

[0045] In addition, it should also be pointed out that in the above technical solution, the abutment portion 4 protrudes at least 1 mm from the end surface of the board body 1 .

[0046] In addition, a protruding protruding structure 7 is provided at the center of the plate body 1 , and the protruding structure 7 and the abutting portion 4 are located on the same side of the plate body 1 .

[0047] The function of the raised structure 3 is to increase the strength of the tension plate and the fixed plate. At the same time, during centrifugation, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com