Adjustable metallographic sample clamp

A metallographic sample, adjustable technology, applied in the direction of manufacturing tools, pliers, etc., can solve the problems of unguaranteed polishing quality, easy flying out of processing efficiency, small application range, etc., to achieve wide application range, low cost, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

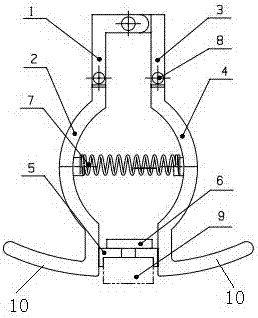

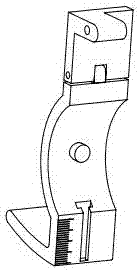

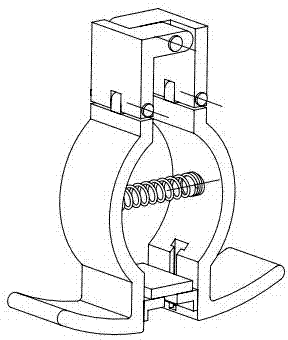

[0019] Such as Figure 1-3 shown.

[0020] An adjustable metallographic sample fixture, which includes a left upper splint 1, a left lower splint 2, a right upper splint 3 and a right lower splint 4, between the left lower splint 2 and the left upper splint 1, between the right lower splint 4 and the right upper splint 3 and The upper left splint 1 and the upper right splint 3 are all inserted into each other and then connected by rivets 8 so as to realize the relative rotation between the two; The tension spring 7; the ends of the left lower splint 2 and the right lower splint 4 have an outwardly protruding arc structure 10, and extra fingers can be placed on it when the sample is polished and polished. For long-term grinding and polishing work Can greatly reduce hand fatigue, more in line with the concept of ergonomics, more humane. In addition, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com