Sealant material, manufacturing method of sealant material, display panel and manufacturing method of display panel

A manufacturing method and frame sealing adhesive technology, which is applied in the direction of adhesive, epoxy resin glue, adhesive type, etc., can solve the problem that the sealing adhesive is easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

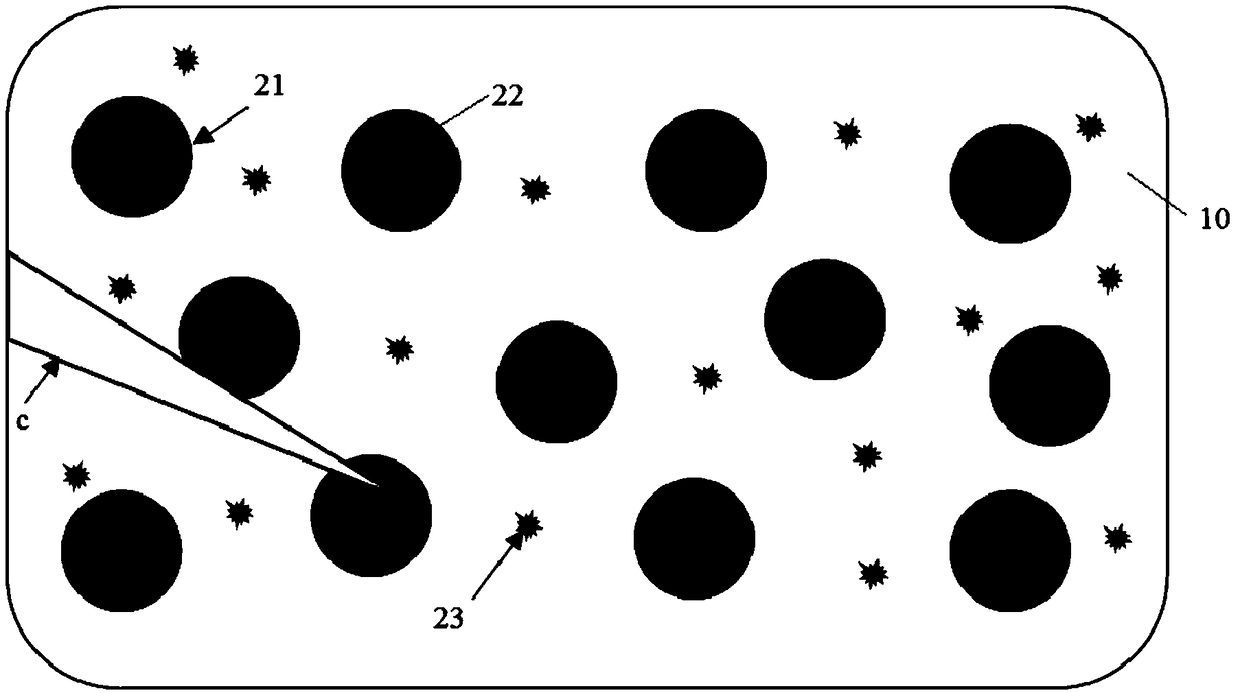

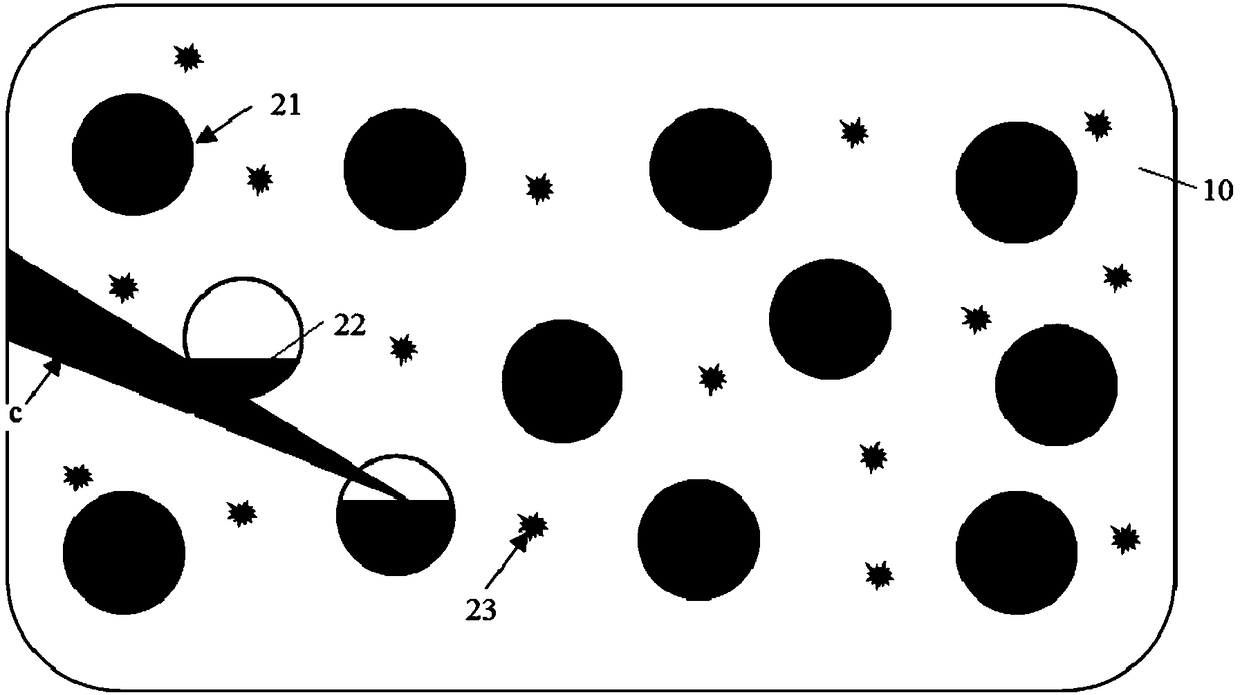

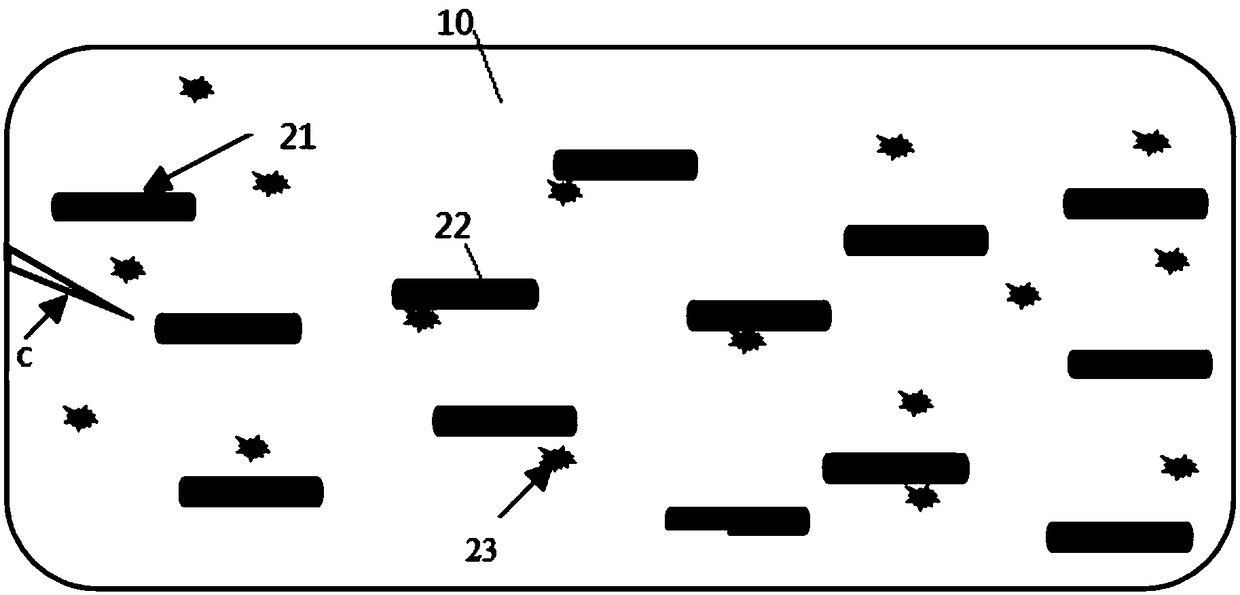

[0026] This embodiment provides a kind of sealing glue material, comprises sealing glue main body material 10, is also distributed with the restoration agent monomer 22 that is wrapped by micro shell 21 in the sealing glue body material 10, and can make restoration agent monomer 22 Catalyst 23 for polymerization.

[0027] The frame sealant material can be applied to display panels such as liquid crystal display panels to form a frame sealant.

[0028] The main body material 10 of the sealant is a material that plays a main role of pasting, and will form the main part of the sealant, for example, it can be acrylic, epoxy or a mixture of the two.

[0029] The sealant material is semi-fluid at normal temperature, and needs to be cured into a solid state sealant after being applied to the liquid crystal display panel. Therefore, the microshell 21 wrapped with the repairing agent monomer 22 and the catalyst 23 capable of polymerizing the repairing agent monomer 22 are also distrib...

Embodiment 2

[0042] This embodiment provides a display panel, such as image 3 As shown, it includes a first substrate b1, a second substrate b2, and a sealant b3 arranged between the first substrate b1 and the second substrate b2 (for a liquid crystal display panel, the sealant b3, the first substrate b1, the second A liquid crystal b4) is also sealed between the substrates b2, and the sealant b3 is formed by curing the sealant material provided in Embodiment 1. The first substrate b1 is, for example, an array substrate, and the second substrate b2 is, for example, a color filter substrate.

[0043] Since the sealant material provided in Example 1 is used to cure and form the sealant b3, when the display panel is damaged (cracks or microcracks, etc.) Catalysts from the broken microshells meet and react to form polymers that fill the broken cracks or microcracks. In this way, defects such as liquid crystal leakage can be avoided.

Embodiment 3

[0045]This embodiment provides a display device, including the display panel provided according to Embodiment 2 of the present invention.

[0046] Specifically, the display device can be any product or component with a display function such as a liquid crystal display module (module, also called a module), an electronic paper, a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, etc. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com