Safety type triangular wire drawing machine for machining cooling fins

A safety-type, heat sink technology, applied in metal processing equipment, grinding/polishing safety devices, manufacturing tools, etc., can solve the problems of poor overall safety, accidents, and complicated personnel operations, so as to improve safety and accuracy , prevent accidents, and the effect of simple operation by personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

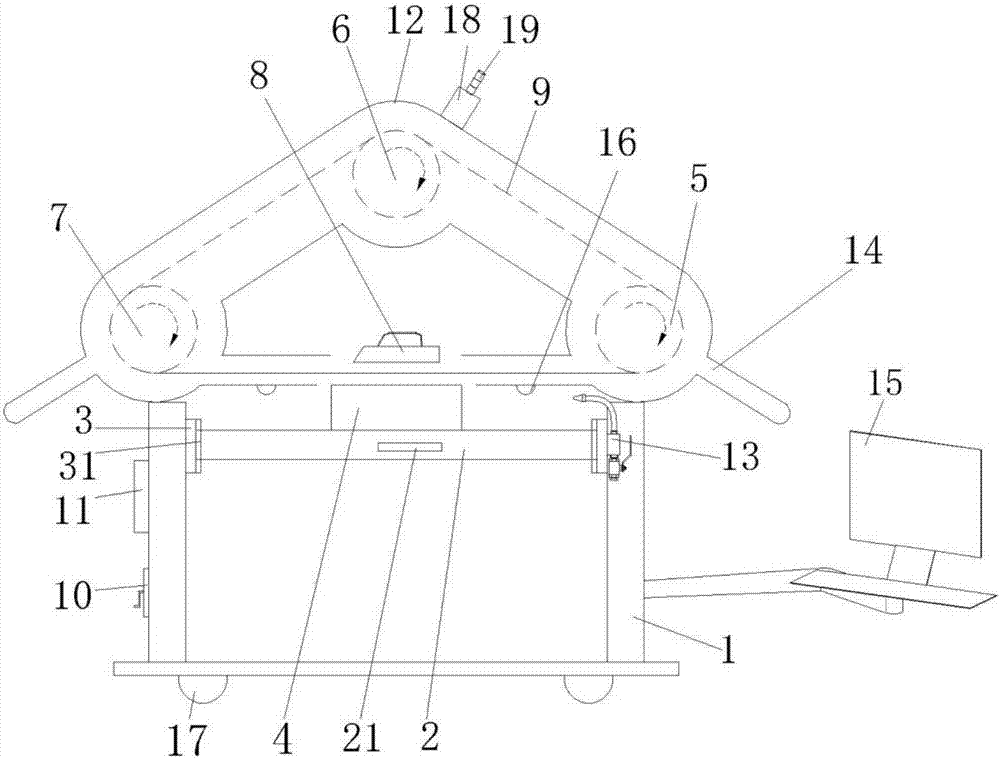

[0030] Such as figure 1 As shown, a safety triangular wire drawing machine for heat sink processing in this embodiment includes a frame 1, a workbench 2, a handle 21, a fixed block 3, a slide rail 31, a first drum 5, a second Drum 6, third drum 7, hand platen 8, sandpaper belt 9, crank handle 10, control panel 11, machine cover 12, cleaning mechanism 13, scrap outlet 14, display 15, visual sensor 16, pulley 17, detection Mechanism 18 and automatic alarm 19.

[0031]The connecting relation of above-mentioned each parts is as follows: described workbench 2 is slidably connected with frame 1 by the fixed block 3 on both sides, and described workbench 2 side is provided with handle 21, and described workbench 2 is arranged on the surface by fixed block 3. Some slide rails 31 move back and forth; one side of the frame 1 is provided with a crank handle 10 and a control panel 11 in turn, the workpiece 4 is placed in the middle of the workbench 2; the machine cover 12 is arranged abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com