Mechanical cutter grinding method of high-precision diamond Vickers pressing head

A diamond, high-precision technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of unreachable nano-hardness measurement, breakage, low precision of diamond indenters, etc., achieve good processing quality, offset processing errors, The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

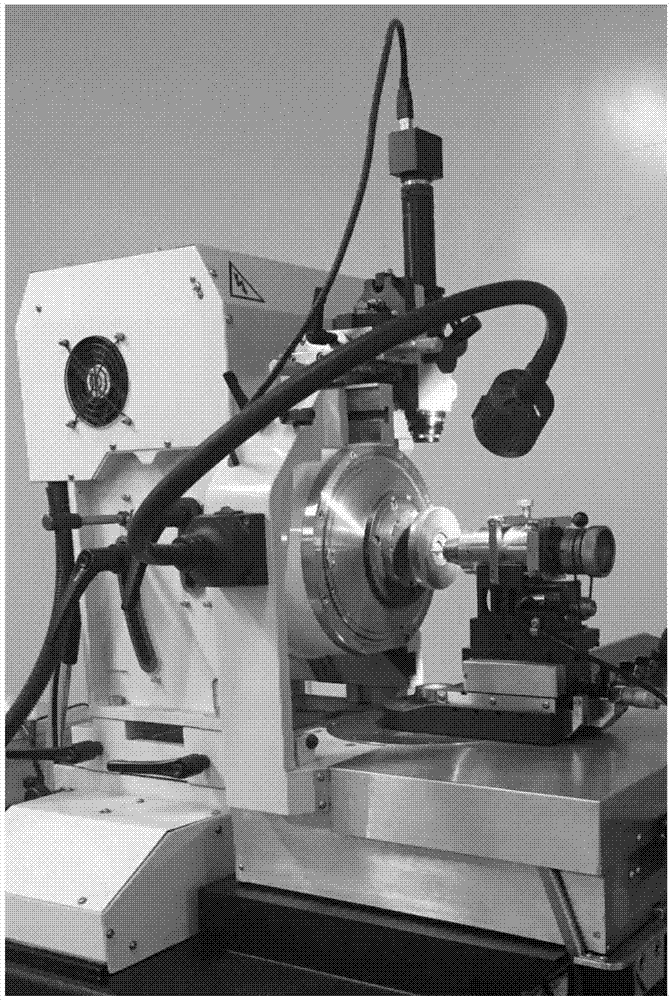

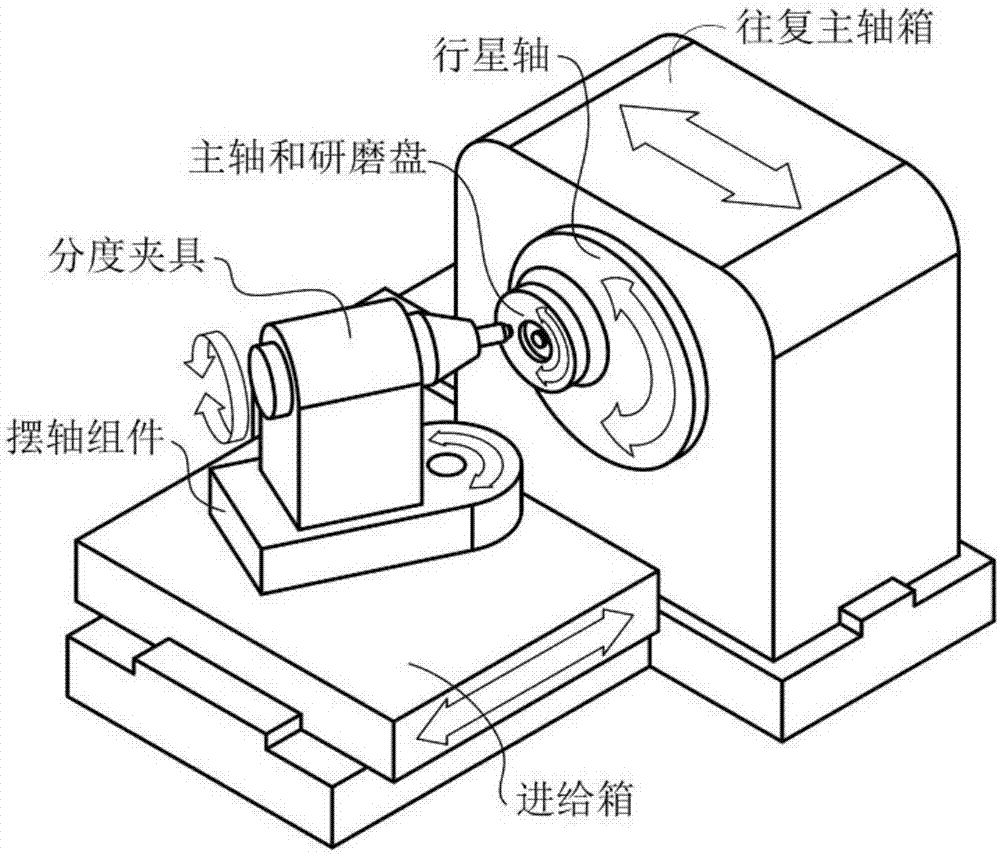

Image

Examples

specific Embodiment approach 1

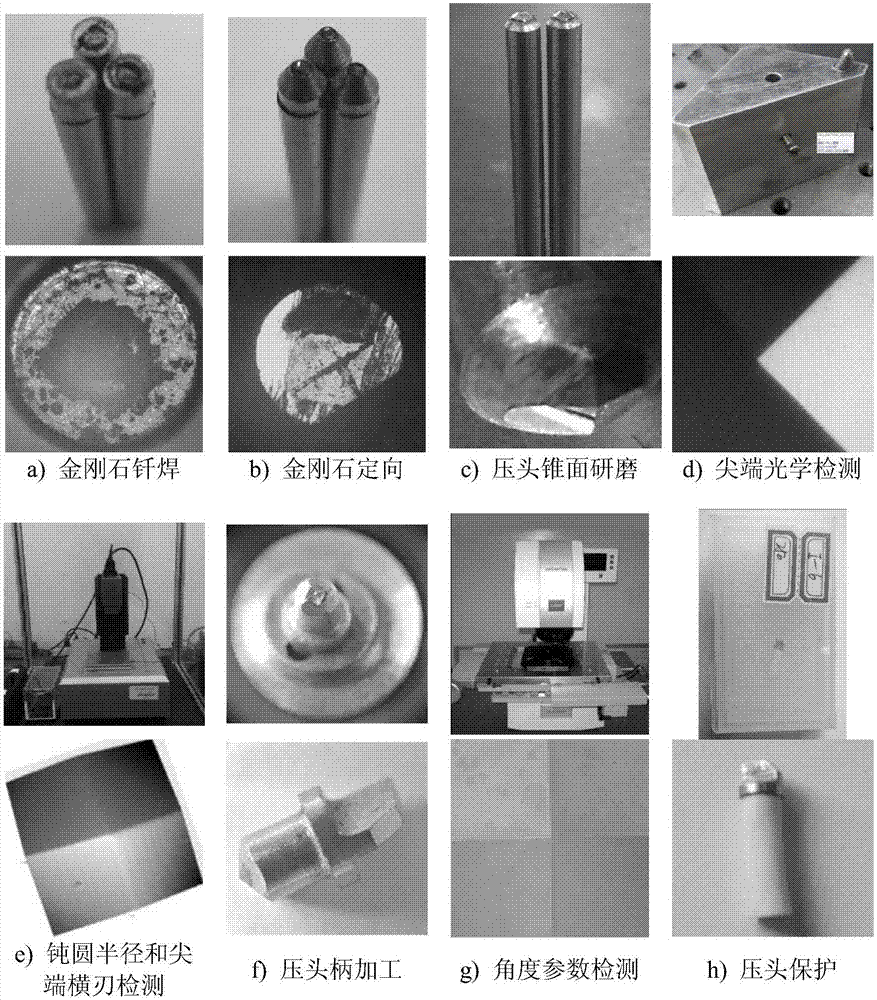

[0041] Specific embodiment one: a kind of mechanical sharpening method of high-precision diamond Vickers indenter, described method step is as follows:

[0042] Step 1: Choose regular hexahedral natural diamond particles as the material of the head of the indenter, and the material of the indenter handle is an iron-nickel alloy with a very low thermal expansion coefficient (this alloy material can maintain a stable length in the temperature range of -80°C to 200°C properties), prepare the indenter handle according to the design parameters of the indenter handle and the particle size of the hexahedral natural diamond, such as image 3 a) as shown;

[0043] A mechanical sharpening method of a high-precision diamond Vickers indenter, the steps of the method are as follows:

[0044] Step 2: Use the vacuum brazing method to realize the stable connection between the diamond particles and the indenter handle; first clean the indenter handle with alcohol to remove pollutants; then, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com