Method for pre-lithiation of cathode pole piece of lithium ion battery

A lithium-ion battery and negative pole piece technology, which is applied in battery electrodes, secondary batteries, secondary battery charging/discharging, etc., can solve the problems of first-time coulombic efficiency reduction, total energy density reduction, battery application barriers, etc., and achieve cost Low, improved safety, uniform lithiation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for pre-lithiation of the negative pole piece of lithium ion battery, comprising the following steps: forming an external short circuit between the positive and negative poles of the button battery.

Embodiment 2

[0030] A method for pre-lithiation of lithium-ion battery negative pole piece, comprising the steps of: forming an external short circuit between the positive and negative poles of a button cell;

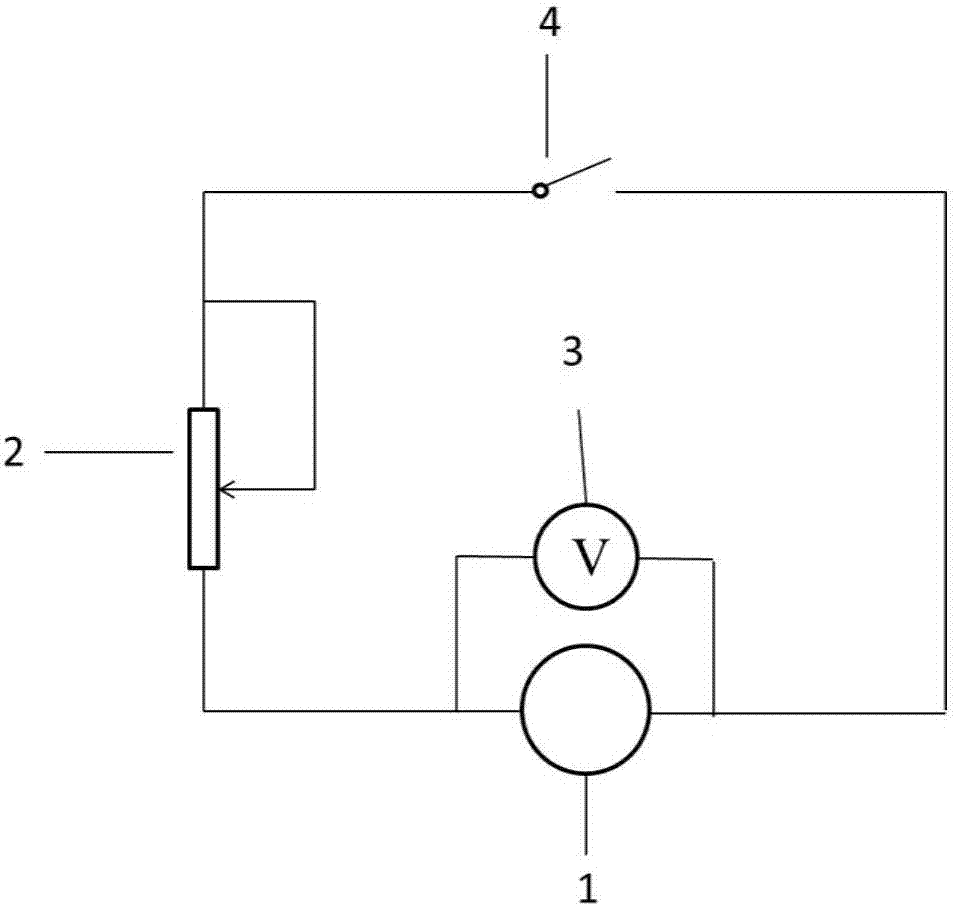

[0031] Wherein, the external short-circuit circuit includes a variable resistor and a voltmeter;

[0032] After forming an external short-circuit circuit between the positive and negative poles of the button battery, keep the short-circuit state for 0.5h;

[0033] The resistance range of the variable resistor is 10-1000Ohm;

[0034] The range of the voltmeter is 0-7V;

[0035] The preparation method of the button battery is as follows: in an atmosphere with a water value<0.1p.p.m and an oxygen value<3p.p.m, sequentially put a negative electrode sheet, an electrolyte, a diaphragm, a positive electrode lithium foil, a gasket, and a spring sheet in the positive electrode shell and the negative electrode case, seal on the sealing machine;

[0036] The preparation method of the negati...

Embodiment 3

[0041] A method for pre-lithiation of lithium-ion battery negative pole piece, comprising the steps of: forming an external short circuit between the positive and negative poles of a button cell;

[0042] Wherein, the external short-circuit circuit includes a variable resistor and a voltmeter;

[0043] After forming an external short-circuit circuit between the positive and negative poles of the button battery, keep the short-circuit state for 1h;

[0044] The resistance range of the variable resistor is 10-1000Ohm;

[0045] The range of the voltmeter is 0-7V;

[0046] The preparation method of the button battery is as follows: in an atmosphere with a water value<0.1p.p.m and an oxygen value<3p.p.m, sequentially put a negative electrode sheet, an electrolyte, a diaphragm, a positive electrode lithium foil, a gasket, and a spring sheet in the positive electrode shell and the negative electrode case, seal on the sealing machine;

[0047] The preparation method of the negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com