Constant-temperature heating and liquid injection device and method of lithium ion battery

A lithium-ion battery, constant temperature heating technology, applied in the manufacture of battery pack parts, non-aqueous electrolyte storage batteries, electrolyte storage batteries, etc., can solve the fluctuation of liquid injection volume of lithium-ion batteries, reduce the production efficiency of lithium-ion batteries, and the liquid injection process Improve the fluidity and wetting performance, improve production efficiency and material utilization, and improve the injection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

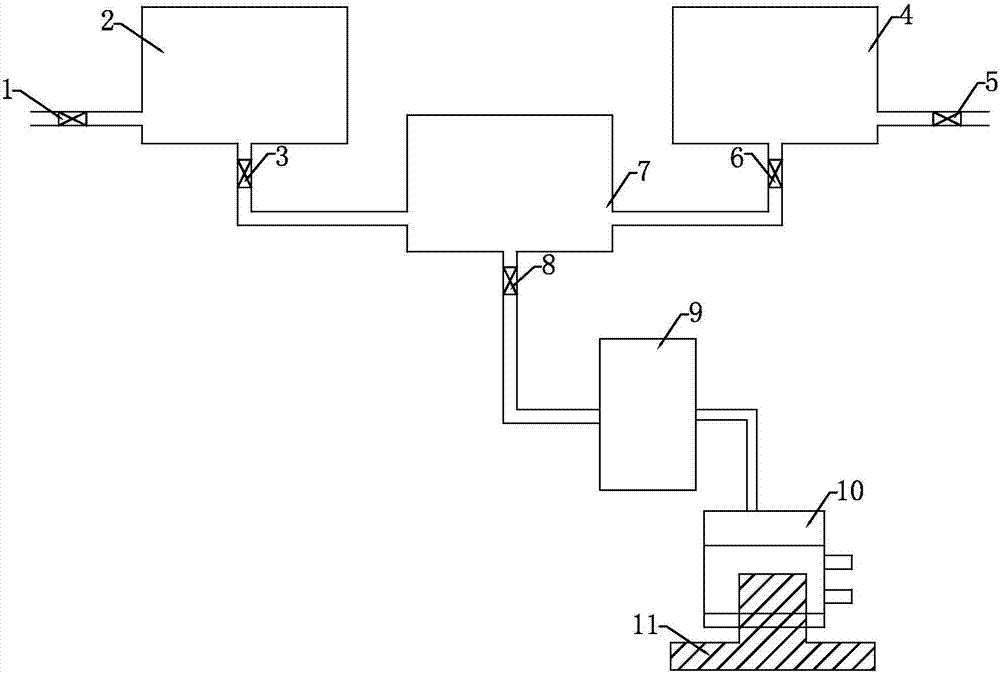

[0030] A lithium ion battery constant temperature heating liquid injection device, including a shell, a first electrolyte heating tank 2, a second electrolyte heating tank 4, an electrolyte constant temperature buffer tank 7, a liquid injection system 9 and a lithium ion battery positioning fixture 11; One end of an electrolyte heating tank is connected to the first liquid inlet valve 1, and the other end is connected to the liquid inlet on the side wall of the electrolyte constant temperature buffer tank through the first electrolyte valve 3; one end of the second electrolyte heating tank is connected to the first The two inlet valves 5 are connected, and the other end is connected to the liquid inlet on the side wall of the electrolyte constant temperature buffer tank through the second electrolyte valve 6; the bottom of the electrolyte constant temperature buffer tank is connected to the liquid injection system through the third electrolyte valve 8 The lithium-ion battery po...

Embodiment 2

[0038] The constant temperature heating liquid injection device for the lithium ion battery is the same as that in Example 1.

[0039] A constant temperature heating liquid injection method for a lithium ion battery, comprising the following steps:

[0040] 1. Dehumidify before liquid injection, so that the dew point temperature in the liquid injection device is lower than -40°C and the temperature is 25°C, and close the first liquid inlet valve, the second liquid inlet valve, the first electrolyte valve, and the second electrolyte valve and third electrolyte valve;

[0041] 2. Open, inject electrolyte into the first electrolyte heating tank and the second electrolyte heating tank, close the first liquid inlet valve and the second liquid inlet valve after completion, heat the electrolyte for 7 minutes, and the temperature of the electrolyte is 35°C , to maintain a constant temperature;

[0042]3. Open the first electrolyte valve, transport the heated electrolyte from the fir...

Embodiment 3

[0046] The constant temperature heating liquid injection device for the lithium ion battery is the same as that in Example 1.

[0047] A constant temperature heating liquid injection method for a lithium ion battery, comprising the following steps:

[0048] 1. Dehumidification before liquid injection, so that the dew point temperature in the liquid injection device is lower than -40°C and the temperature is 30°C, and close the first liquid inlet valve, the second liquid inlet valve, the first electrolyte valve, and the second electrolyte valve and third electrolyte valve;

[0049] 2. Open, inject electrolyte into the first electrolyte heating tank and the second electrolyte heating tank, close the first liquid inlet valve and the second liquid inlet valve after completion, heat the electrolyte for 10 minutes, and the temperature of the electrolyte is 40 ℃ , to maintain a constant temperature;

[0050] 3. Open the first electrolyte valve, transport the heated electrolyte from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com