Method for manufacturing artistic punched decorative plate by adopting characteristic-based hole layout design

A manufacturing method and technology of decorative boards, applied in computing, special data processing applications, instruments, etc., can solve the problems of inhibiting the quality and added value of artistic punching decorative boards, weak performance of image detail features, and blurred imaging effects, etc., to achieve Improve product quality and added value, optimize imaging capabilities and product quality, and improve imaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

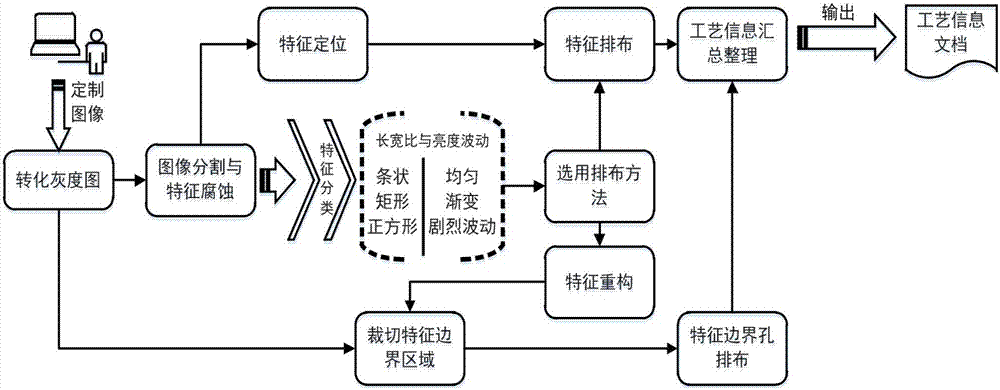

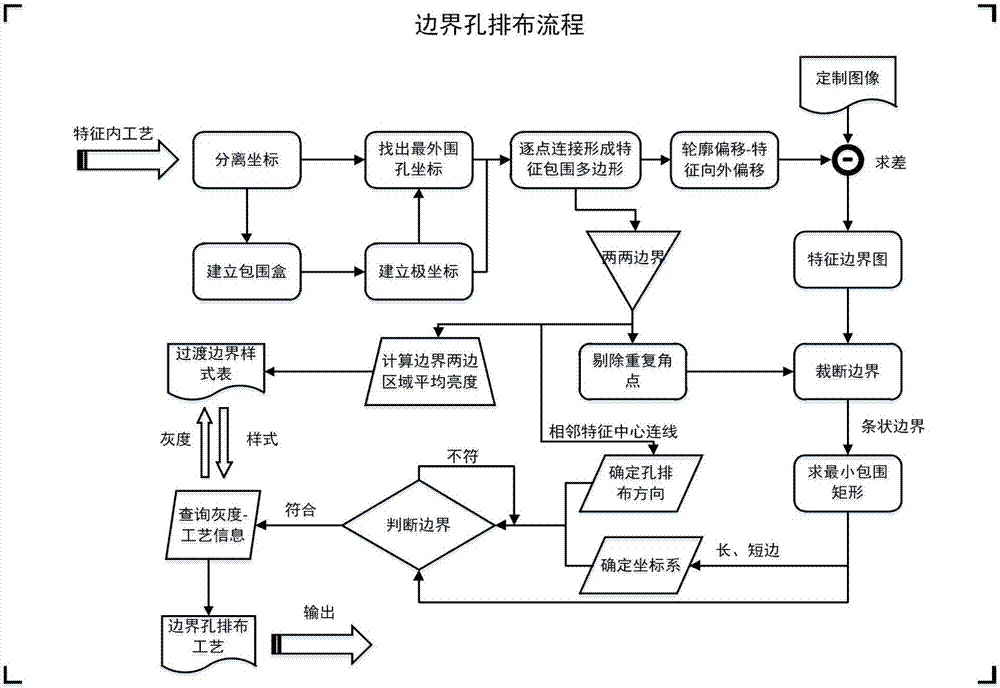

[0049] A method for manufacturing an artistic punching decorative plate based on feature-based hole arrangement design, comprising the steps of:

[0050] (1) Import the color customized image of the hole decorative plate into the system and convert it into a grayscale image;

[0051] (2) performing feature segmentation on the grayscaled image to form multiple independent feature regions;

[0052] (3) Arrangement of characteristic inner holes:

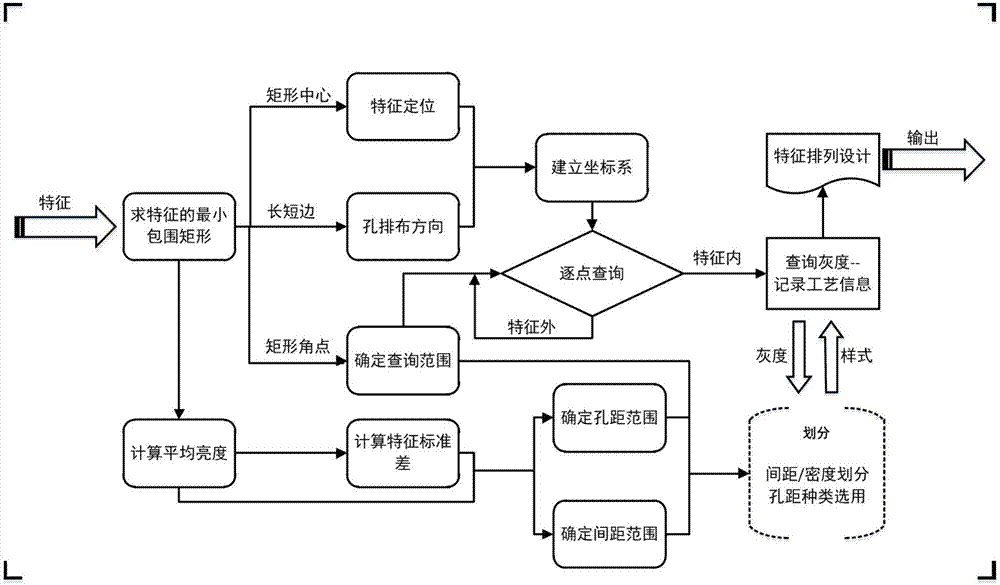

[0053] a. Feature positioning and feature classification: feature positioning is performed according to the minimum enclosing rectangle of the feature area, and the hole arrangement direction and query range are determined; features are classified according to the aspect ratio of the feature and the fluctuation degree of brightness change;

[0054]b. Select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com