Post-tensioned prestressing assembling concrete frame anti-seismic and energy-consuming component system and construction method

A post-tensioning prestressing and prestressing technology, which is applied to building components, truss structures, and earthquake resistance, can solve problems such as low structural robustness, high cost of energy-consuming steel bars, and difficulty in transportation and hoisting. Difficulty, good seismic performance, and the effect of improving the level of green construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

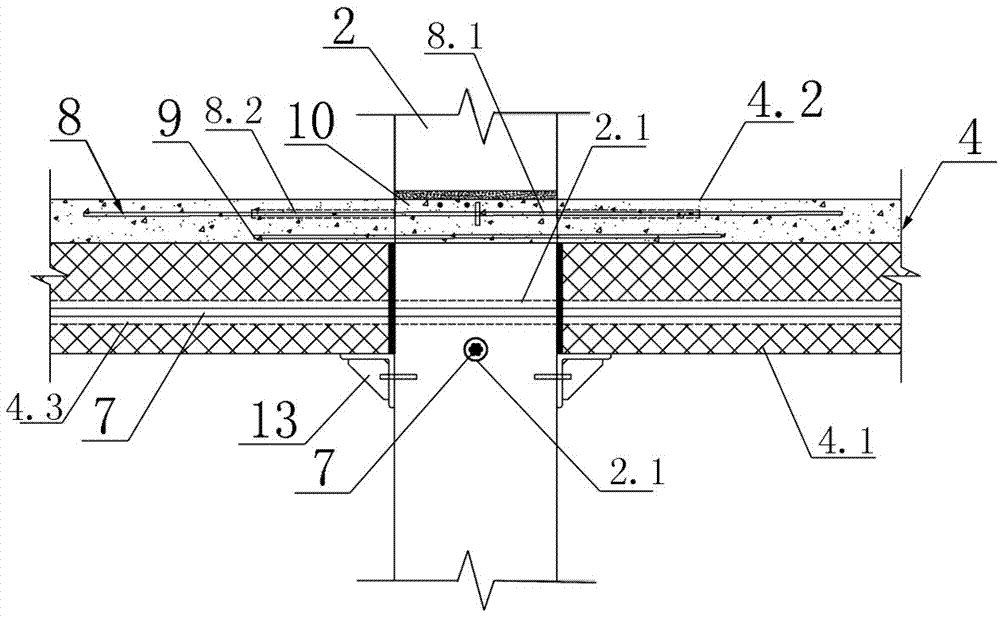

[0075] Example 1, such as Figure 10 and 11 As shown, the anti-seismic energy dissipation component is an anti-seismic wall 3; the anti-seismic wall 3 includes a shear energy dissipator 3.2 and a shear wall 3.3; the shear wall 3.3 is integrally formed, and the The bottom of the body 3.3 is provided with vertical sleeves 3.1 at intervals, and the bottom of the shear wall 3.3 and the laminated main beam 4 below it or between the shear wall 3.3 and the foundation 1 are connected by grouting through the vertical sleeve 3.1; The shear-type energy dissipator 3.2 is installed on the top of the shear wall 3.3, and connects the shear wall 3.3 with the laminated girder 4 above it; in other embodiments, the bottom of the shear wall 3.3 is connected to the The laminated main girders 4 below or between the shear wall body 3.3 and the foundation 1 can also be connected by dry connectors 14 .

[0076] In this embodiment, the dry connector 14 is a bolt connection.

[0077] In this example,...

Embodiment 2

[0095] Example 2, such as Figure 14 As shown, when the anti-seismic energy-dissipating member in this embodiment is a buckling-constrained steel support 11; the steel support 11 provides lateral stiffness for the structure under frequent earthquakes, and provides structure for the structure under fortification earthquakes or rare earthquakes. In terms of energy dissipation capacity, the shape of the steel support 11 can be human-shaped or V-shaped or W-shaped.

[0096] The construction steps of the post-tensioned prestressed assembled concrete frame anti-seismic energy-dissipating component system in this implementation example are as follows.

[0097] Step 1, producing prefabricated components in the factory, including producing frame columns 2, precast concrete main beams 4.1, precast hollow slabs 5.1, precast concrete secondary beams 6.1 and steel supports 11; the frame columns 2 and precast concrete main beams 4.1 are buried There are node connecting plates 15 for connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com