Antibacterial flame-retardant polyamide 66 fabric and preparation method thereof

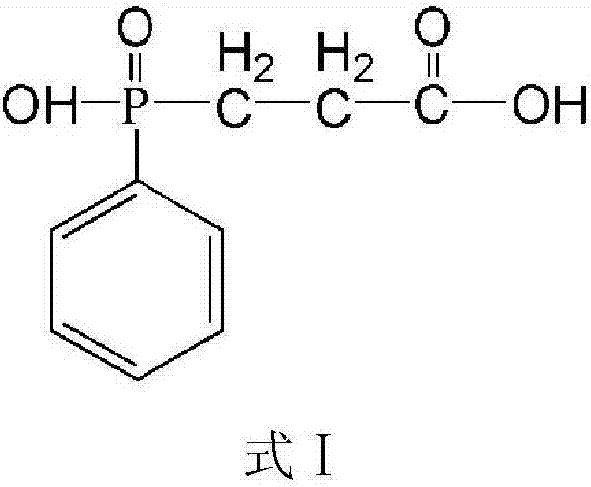

A technology of flame-retardant polyamide and polyamide, which is applied in the manufacture of fire-resistant and flame-retardant filaments, conjugated synthetic polymer artificial filaments, and rayon. It can solve the problems of large antibacterial doses, complicated processes, and limited antibacterial effects. , to achieve the effect of improving antibacterial and flame retardancy, lasting antibacterial effect, and stable antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

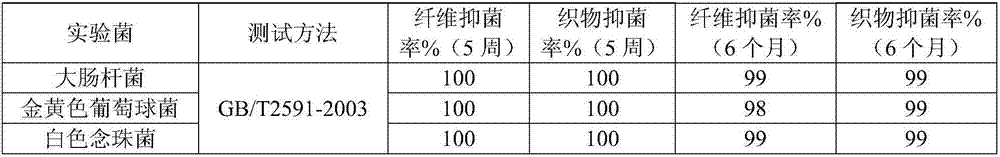

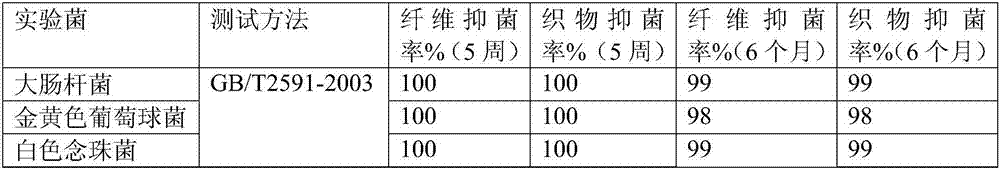

Examples

Embodiment 1

[0055] Embodiment 1, the preparation of antibacterial flame-retardant polyamide 66

[0056] 1. Preparation of flame retardant prepolymer:

[0057] 1) Mix the flame retardant CEPPA, ethylenediamine, ethylene glycol and water in a ratio of 1:1.1:1:100 (mol), and the mixing time is 0.5h;

[0058] 2) After mixing evenly, stir and react under nitrogen protection at 50°C for 1 hour;

[0059] 3) After stirring and reacting, pressurize to 0.2MPa, and further heat up to 180°C under the protection of nitrogen to carry out polymerization reaction, and prepare flame retardant prepolymer after reacting for 1 hour;

[0060] 4) The weight average molecular weight of the prepared flame retardant prepolymer is 2000.

[0061] 2. Preparation of antibacterial and flame retardant polyamide 66

[0062] 1) Concentrate 52% nylon 66 salt to 80% at 150°C;

[0063] 2) Raise the temperature to 200°C for reaction, the polymerization pressure is 1.7MPa, hold the pressure for 50 minutes, and release the...

Embodiment 2

[0075] Embodiment 2, the preparation of antibacterial flame-retardant polyamide 66

[0076] 1. Preparation of flame retardant prepolymer

[0077] 1) Mix the flame retardant DDP, ethylenediamine, ethylene glycol and water in a ratio of 1:1.2:1:50 (mol), and the mixing time is 1h;

[0078] 2) After mixing evenly, stir and react under nitrogen protection at 90°C for 1.5h;

[0079] 3) After stirring and reacting, pressurize to 0.2MPa, and further raise the temperature to 190°C under the protection of nitrogen to carry out polymerization reaction, and prepare the flame retardant prepolymer after reacting for 2 hours;

[0080] 4) The weight average molecular weight of the prepared flame retardant prepolymer is 3000.

[0081] 2. Preparation of antibacterial and flame retardant polyamide 66

[0082] 1) Concentrate 52% nylon 66 salt to 80% at 150°C;

[0083] 2) Raise the temperature to 210°C for reaction, the polymerization pressure is 2.2MPa, hold the pressure for 1.5h, and releas...

Embodiment 3

[0095] Embodiment 3, the preparation of antibacterial flame-retardant polyamide 66

[0096] 1. Preparation of flame retardant prepolymer

[0097] 1) Mix the flame retardant DDP sodium salt, propylenediamine, propylene glycol and water in a ratio of 1:1.18:1:80 (mol), and the mixing time is 0.5h;

[0098] 2) After mixing evenly, stir and react under nitrogen protection at 55°C for 1 hour;

[0099] 3) After the stirring reaction, pressurize to 0.2MPa, and further raise the temperature to 182°C under the protection of nitrogen to carry out the polymerization reaction, and prepare the flame retardant prepolymer after reacting for 1.5h;

[0100] 4) The weight average molecular weight of the prepared flame retardant prepolymer is 2500.

[0101] 2. Preparation of antibacterial and flame retardant polyamide 66

[0102] 1) Concentrate 52% nylon 66 salt to 80% at 150°C;

[0103] 2) Raise the temperature to 205°C for reaction, the polymerization pressure is 2MPa, hold the pressure fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com