A rare earth substance extraction device

A technology for extracting devices and substances, applied in the field of rare earth substance extraction devices, can solve the problems of affecting the extraction of rare earth substances, foreign substances easily falling into rare earths, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

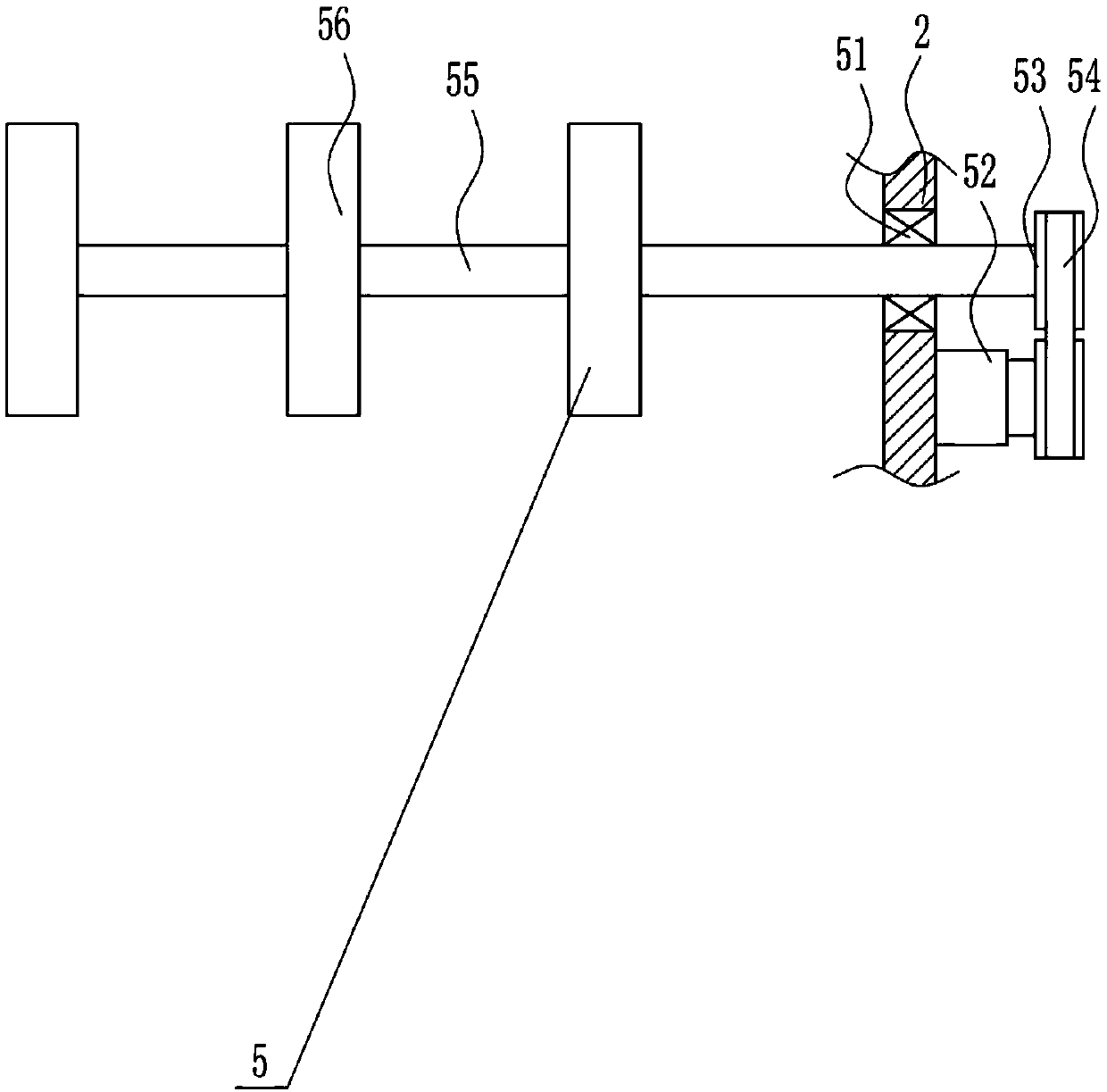

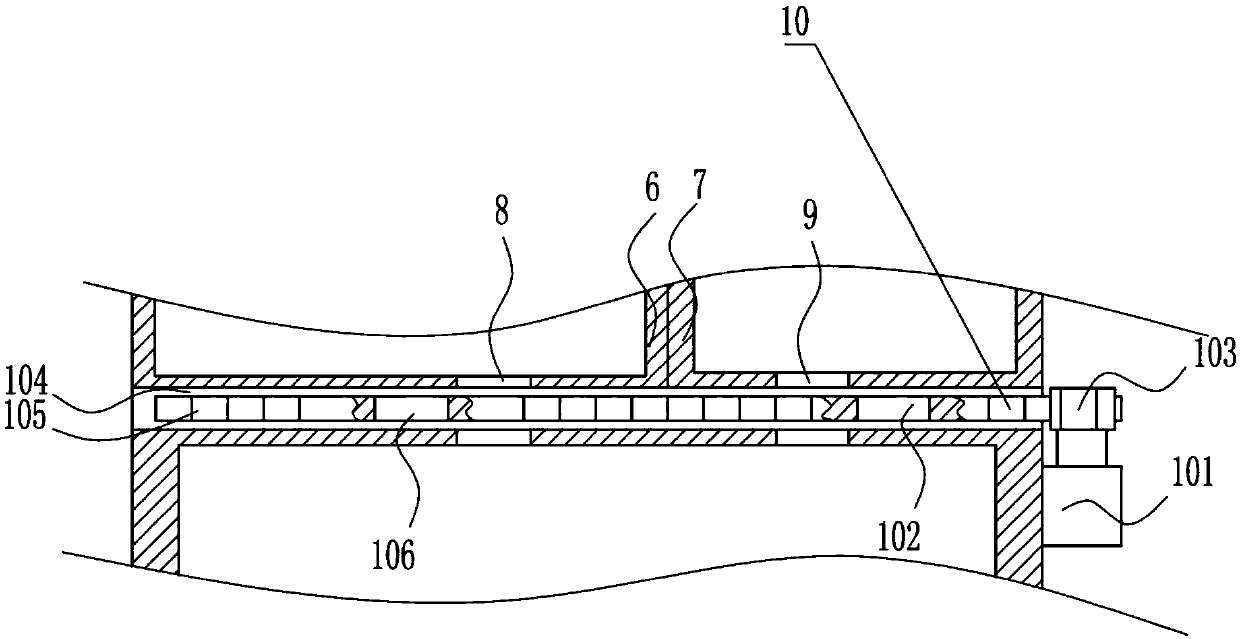

[0037] A rare earth material extraction device, such as Figure 1-7 As shown, it includes support leg 1, stirring box 2, iron block 3, box cover 4, stirring device 5, placement box 6, liquid tank 7 and moving device 10, and supporting leg 1 is installed on the outer bottom of stirring box 2, and stirring box 2 is provided with a stirring device 5, the left side of the mixing box 2 is provided with a box cover 4, the top of the box cover 4 is connected with the upper left side of the mixing box 2 by pins, the bottom of the box cover 4 is installed with an iron block 3, and the left side of the mixing box 2 is lower. A magnet 16 is installed, and the magnet 16 is in contact with the iron block 3. A placement box 6 is installed on the left side of the top of the stirring box 2. A discharge port 8 is opened on the right side of the bottom of the placing box 6. A liquid tank 7 is installed on the right side of the outer top of the stirring box 2. , the bottom left side of the liqui...

Embodiment 2

[0039] A rare earth material extraction device, such as Figure 1-7 As shown, it includes support leg 1, stirring box 2, iron block 3, box cover 4, stirring device 5, placement box 6, liquid tank 7 and moving device 10, and supporting leg 1 is installed on the outer bottom of stirring box 2, and stirring box 2 is provided with a stirring device 5, the left side of the mixing box 2 is provided with a box cover 4, the top of the box cover 4 is connected with the upper left side of the mixing box 2 by pins, the bottom of the box cover 4 is installed with an iron block 3, and the left side of the mixing box 2 is lower. A magnet 16 is installed, and the magnet 16 is in contact with the iron block 3. A placement box 6 is installed on the left side of the top of the stirring box 2. A discharge port 8 is opened on the right side of the bottom of the placing box 6. A liquid tank 7 is installed on the right side of the outer top of the stirring box 2. , the bottom left side of the liqui...

Embodiment 3

[0042] A rare earth material extraction device, such as Figure 1-7 As shown, it includes support leg 1, stirring box 2, iron block 3, box cover 4, stirring device 5, placement box 6, liquid tank 7 and moving device 10, and supporting leg 1 is installed on the outer bottom of stirring box 2, and stirring box 2 is provided with a stirring device 5, the left side of the mixing box 2 is provided with a box cover 4, the top of the box cover 4 is connected with the upper left side of the mixing box 2 by pins, the bottom of the box cover 4 is installed with an iron block 3, and the left side of the mixing box 2 is lower. A magnet 16 is installed, and the magnet 16 is in contact with the iron block 3. A placement box 6 is installed on the left side of the top of the stirring box 2. A discharge port 8 is opened on the right side of the bottom of the placing box 6. A liquid tank 7 is installed on the right side of the outer top of the stirring box 2. , the bottom left side of the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com