Device and method for extracting and separating lignin in papermaking black liquor

A technology for papermaking black liquor and lignin, which is applied in the regeneration of lye and other directions, can solve the problems of large amount of acid-extracted foam, less extraction amount, slow lignin extraction speed, etc. Extract the effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

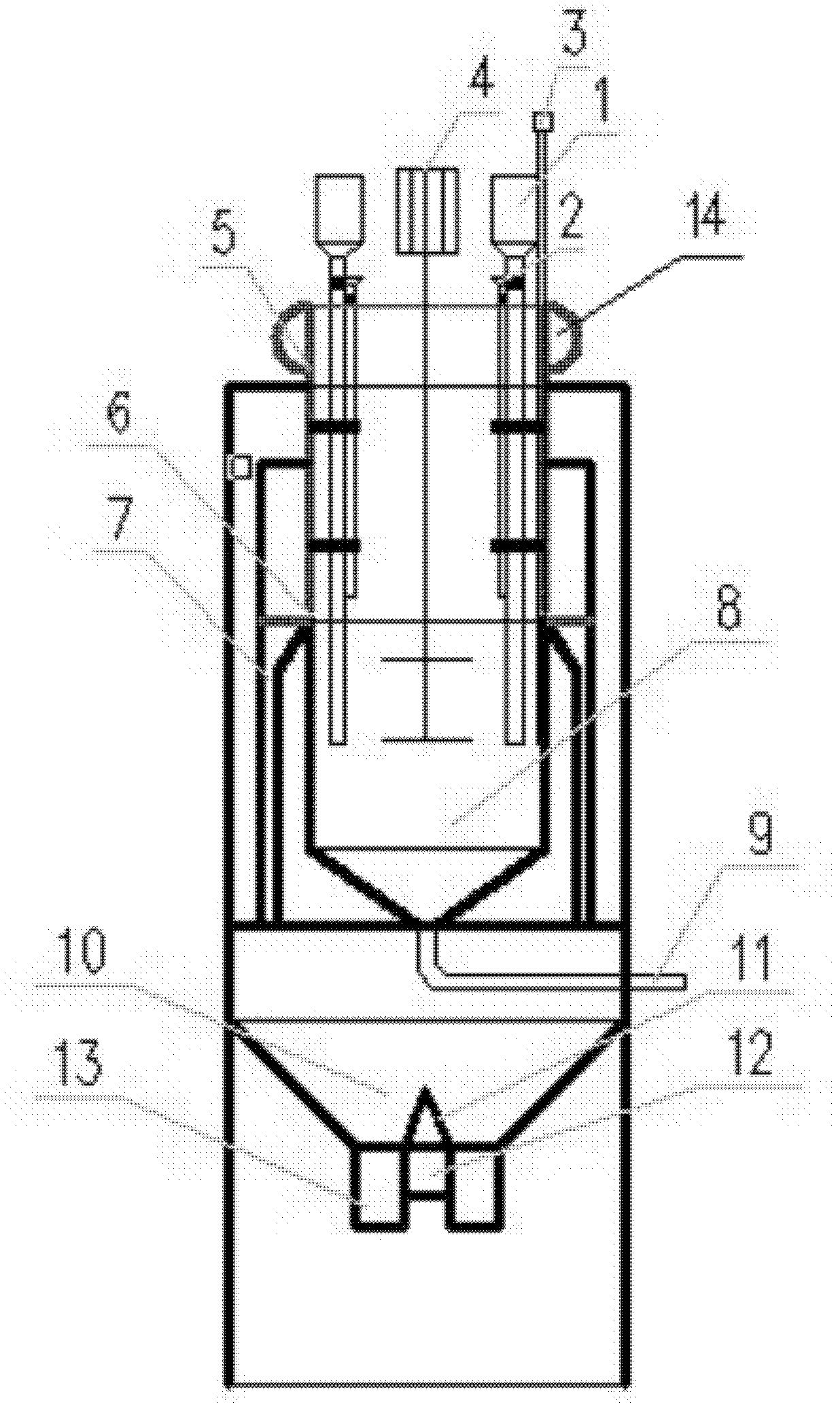

[0035] Such as figure 1 As shown, the device for extracting and separating lignin from papermaking black liquor of the present invention mainly includes an acid analysis flocculation zone 8 , a blocking bucket 5 and a separation zone 10 .

[0036]The acid analysis flocculation zone 8 has a barrel-shaped main body and a conical bottom. Its upper part is open, and the bottom of the lower cone is provided with a separation liquid outlet. The separation liquid outlet is connected to the separation liquid conduit 9 leading the separation liquid out of the device.

[0037] The opening of the blocking bucket 5 is downward, and the upper opening end of the acid analysis flocculation zone 8 is tightly and flexibly connected with the lower opening end of the blocking bucket 5, so that water or black liquor will not flow out or seep out from the connection.

[0038] There are als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com