Dustproof and static conductive environmental protection coating for air purifying equipment

A technology for air purification equipment and environmental protection coatings, applied in conductive coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of cumbersome preparation and construction process, high VOC content, poor weather resistance, etc., to improve dust resistance and resistance. Excellent stain resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

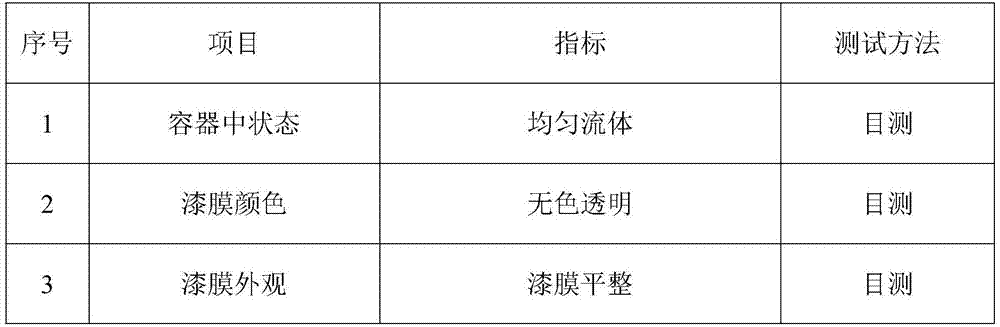

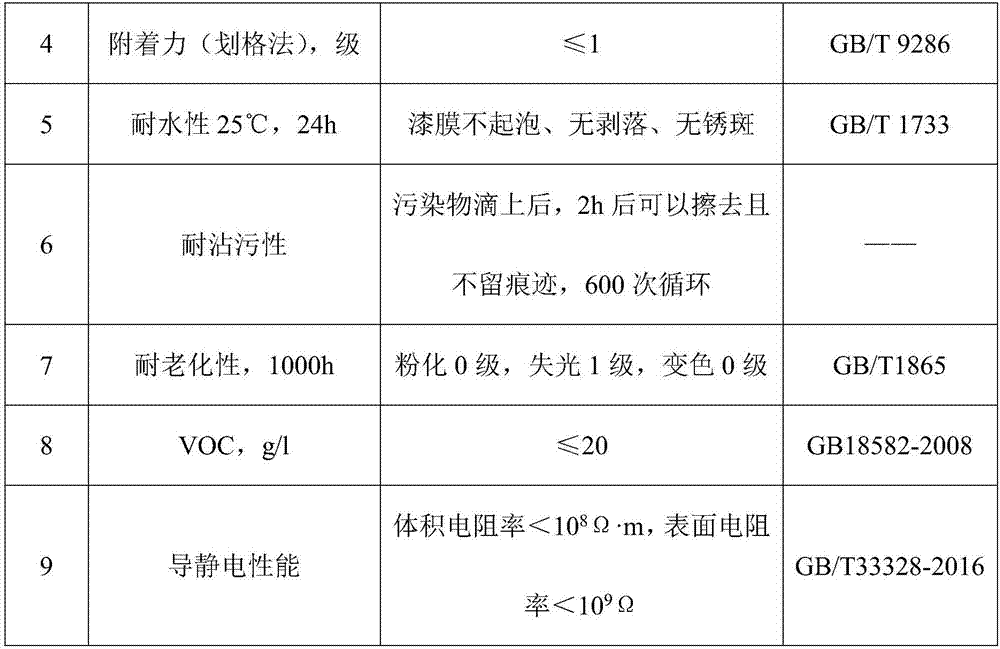

[0035] In Example 1, the nano-titanium dioxide aqueous dispersion and the lotus-leaf effect additive were added at the same time in the present invention, and in Comparative Examples 1-2, only the nano-titanium dioxide aqueous dispersion and the lotus-leaf effect additive were added.

Embodiment 2

[0036] 5% graphene aqueous dispersion was added in Example 2, and 2%, 3%, and 6% graphene aqueous dispersion were added in Comparative Examples 3-5.

Embodiment 3

[0037] In Example 3, 20% of rutile-type titanium dioxide was added, and in Comparative Examples 6-7, 15% and 25% of rutile-type titanium dioxide were respectively added.

[0038] 40-45 parts of water-based fluorocarbon emulsion, 2-3 parts of film-forming aids, 15-20 parts of fillers, 0.3-0.5 parts of rheological additives, 1-1.5 parts of leveling agents, 0.7-1 parts of defoamers, dispersed 0.5-1.5 parts of agent, 1-3 parts of thickener, 0.1-0.2 parts of PH regulator, 0.5-1.5 parts of lotus leaf effect additive, 1-2 parts of nano-titanium dioxide aqueous dispersion, 3-5 parts of graphene dispersion, 13-15 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com