Method for preparing anticoagulant composite coating

A composite coating and anti-coagulation technology, which is applied in coatings, pharmaceutical formulations, surgery, etc., can solve the problems of anti-coagulation effects, high cost, and difficulty in meeting clinical requirements, and achieve prolongation of thromboplastin time, Excellent biocompatibility, excellent anticoagulant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

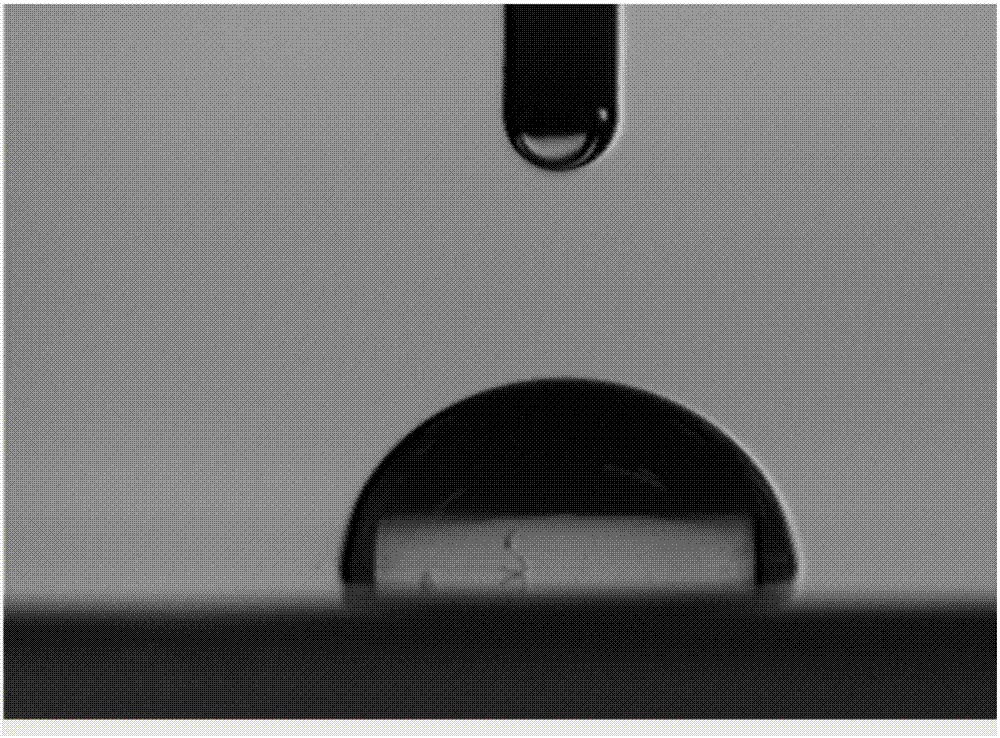

[0029] A method for modifying PVC sheet with anticoagulant composite coating, the specific steps are as follows:

[0030] Dissolve 50mg of polyvinyl alcohol 1788 in 5ml of deionized water and dissolve in a constant temperature water bath at 50°C, add 25mg of polyvinylpyrrolidone under stirring conditions, and add 2.5mg of heparin sodium when it is completely dissolved; add 5mg of chitosan into 5ml of deionized water, Add 50-100ul of glacial acetic acid dropwise under stirring until the solution is clear. After uniformly mixing the above two solutions, 200-500 ul of glutaraldehyde solution with a concentration of 2.5% by mass was added dropwise under the condition of stirring, and then 10 mg of glycerin was added and stirred evenly to obtain an anticoagulant and anticoagulant composite coating. Clean the PVC sheet with a size of 2 × 2 (cm) with medical alcohol, vacuum dry it with 1% silane coupling agent N-(β-aminoethyl)-γ-aminopropyltrimethoxy After immersing in the base sila...

Embodiment 2

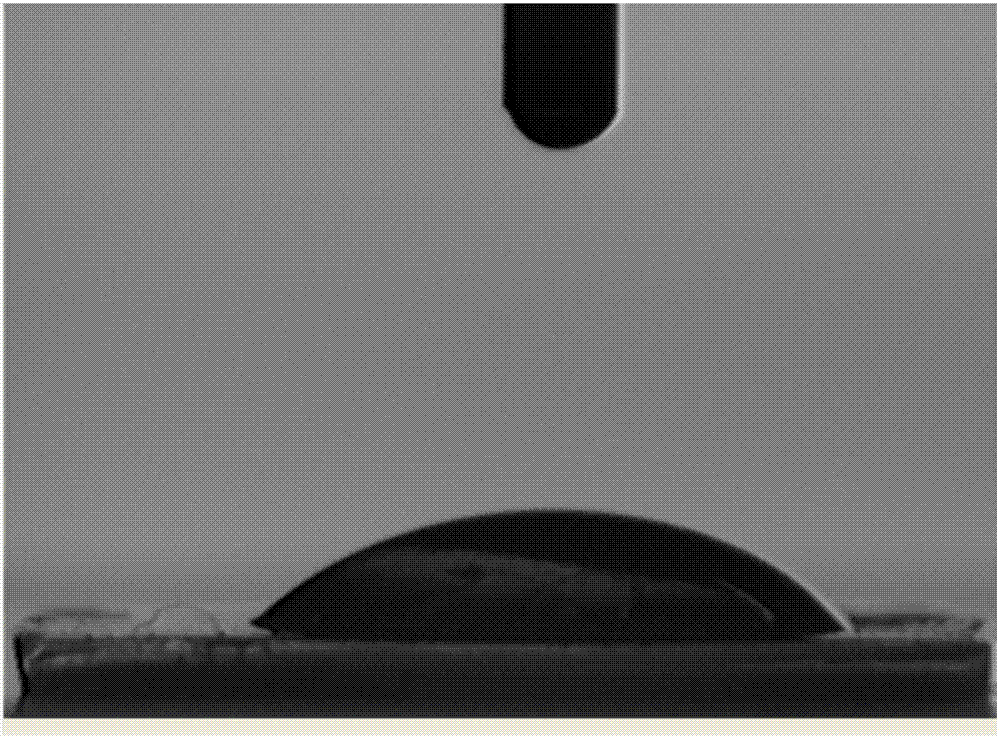

[0032] A method for modifying PVC sheet with anticoagulant composite coating, the specific steps are as follows:

[0033] Dissolve 100mg of polyvinyl alcohol 1788 in 5ml of deionized water and dissolve in a constant temperature water bath at 50°C, add 50mg of polyvinylpyrrolidone under stirring conditions, and add 5mg of heparin sodium when it is completely dissolved; add 25mg of chitosan into 5ml of deionized water, Add 100-200ul of glacial acetic acid dropwise under stirring until the solution is clear. After uniformly mixing the above two solutions, add 200-500 ul of glutaraldehyde solution with a mass percent concentration of 2.5% dropwise under stirring conditions, and then add 25 mg of glycerin and stir evenly to obtain an anticoagulant and anticoagulant composite coating. Clean the PVC sheet with a size of 2 × 2 (cm) with medical alcohol, vacuum dry it with 1% silane coupling agent N-(β-aminoethyl)-γ-aminopropyltrimethoxy After immersing in the base silane solution for...

Embodiment 3

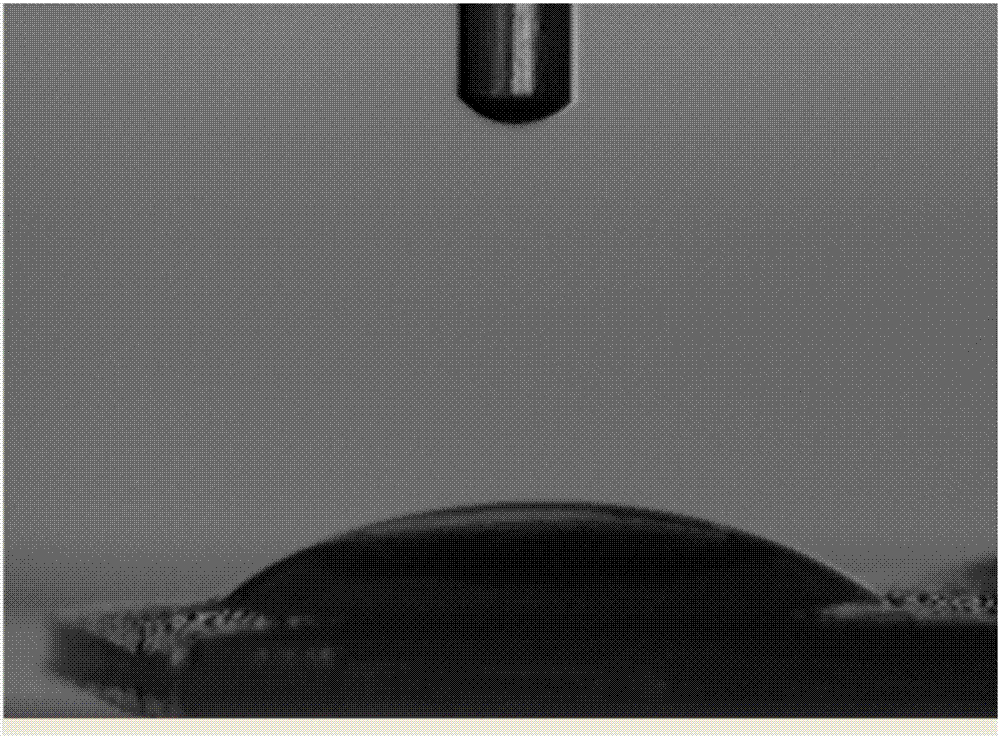

[0035] A method for modifying PVC sheet with anticoagulant composite coating, the specific steps are as follows:

[0036] Dissolve 200mg of polyvinyl alcohol 1788 in 5ml of deionized water and dissolve in a constant temperature water bath at 50°C, add 100mg of polyvinylpyrrolidone under stirring conditions, and add 5mg of heparin sodium when it is completely dissolved; add 30mg of chitosan into 5ml of deionized water, Add 100-200ul of glacial acetic acid dropwise under stirring until the solution is clear. After uniformly mixing the above two solutions, add 200-500 ul of glutaraldehyde solution with a mass percent concentration of 2.5% dropwise under stirring conditions, and then add 20 mg of glycerin and stir evenly to obtain an anticoagulant and anticoagulant composite coating. Clean the PVC sheet with a size of 2 × 2 (cm) with medical alcohol, vacuum dry it with 1% silane coupling agent N-(β-aminoethyl)-γ-aminopropyltrimethoxy After immersing in the base silane solution fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com