Cleaning device

A technology for cleaning and cleaning areas, applied in textile and paper making, paper machine, wet end of paper machine, etc., can solve the problems of environmental pollution and high energy consumption, and achieve the effect of reducing pollution and improving cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

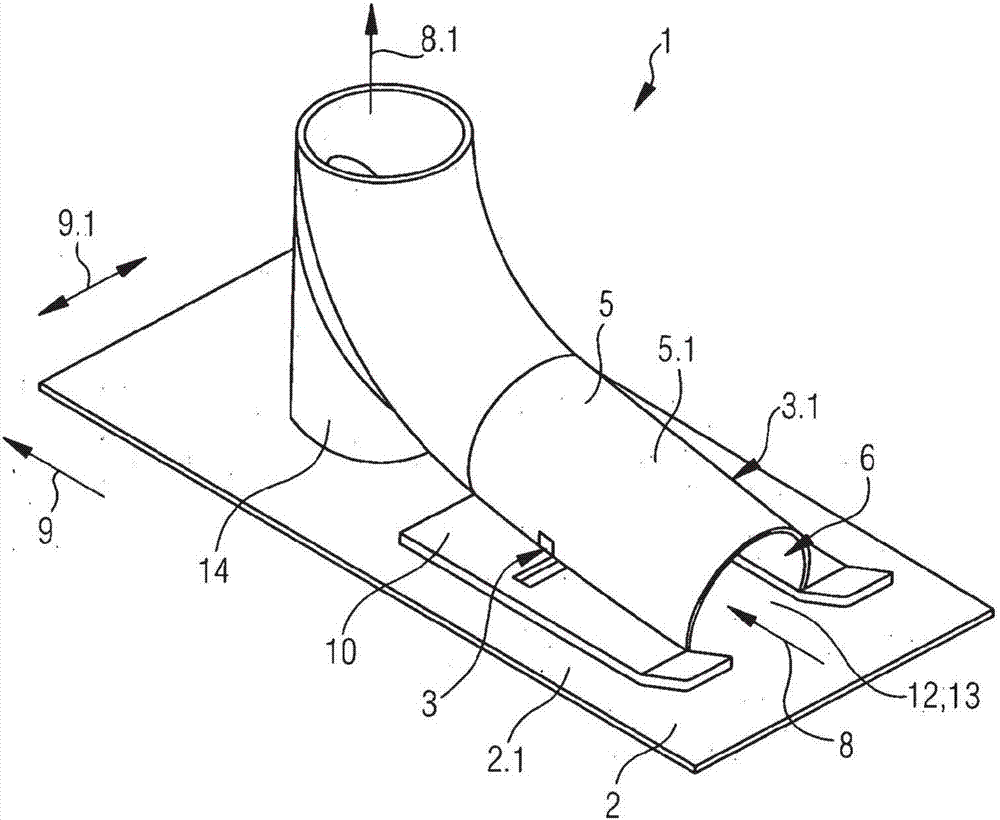

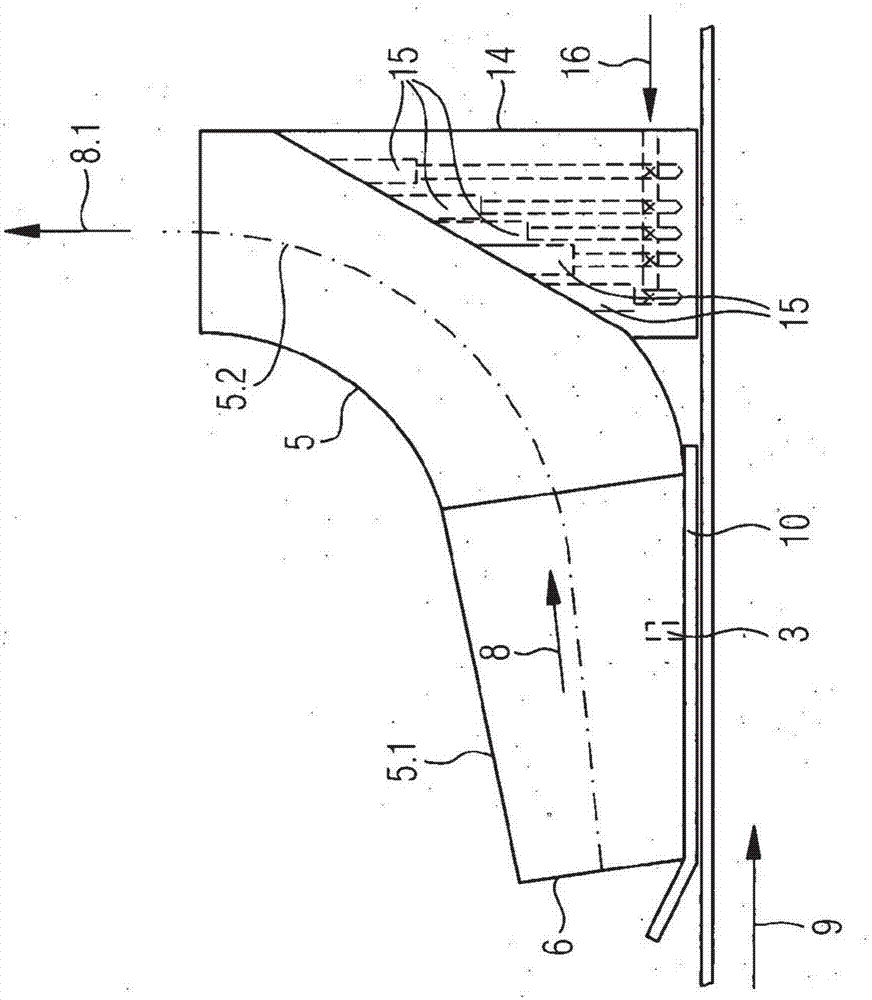

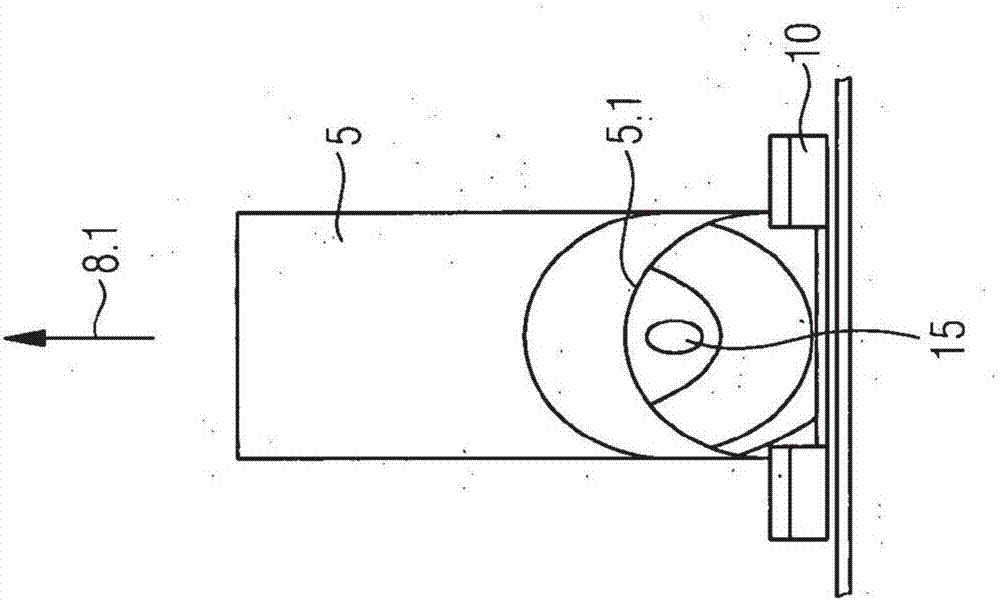

[0058] exist figure 1 The device 1 according to the invention is shown schematically and in perspective in FIG. The stretched wire 2 shown in fragments is a drying wire which runs around in the running direction 9 and is used for drying a fibrous web in the drying section of a paper machine. The device 1 is connected to a spanning device, not shown, and is moved back and forth in the transverse direction 9 . 1 continuously or at intervals during cleaning. Thus, the entire surrounding stretcher 2 , which spreads the stretcher plane 2 . 1 in the region of the device 1 , can be cleaned. The device 1 comprises a discharge channel 5 having a first section 5.1. It is made of a tube and therefore has no right-angled or sharp-angled corners on the inside. The tendency to contamination is therefore very small. The first section 5 . 1 has a receiving opening 6 . The device 1 is arranged relative to the drying wire 2 in such a way that the receiving opening 6 points opposite to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com