Method for preparing highly nitrogen-doped mesoporous carbon composites

A composite material, high-level technology, applied in the direction of hydrocarbons, hydrocarbons, carbon compound catalysts, etc., can solve problems such as difficult material processing in scale-up procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

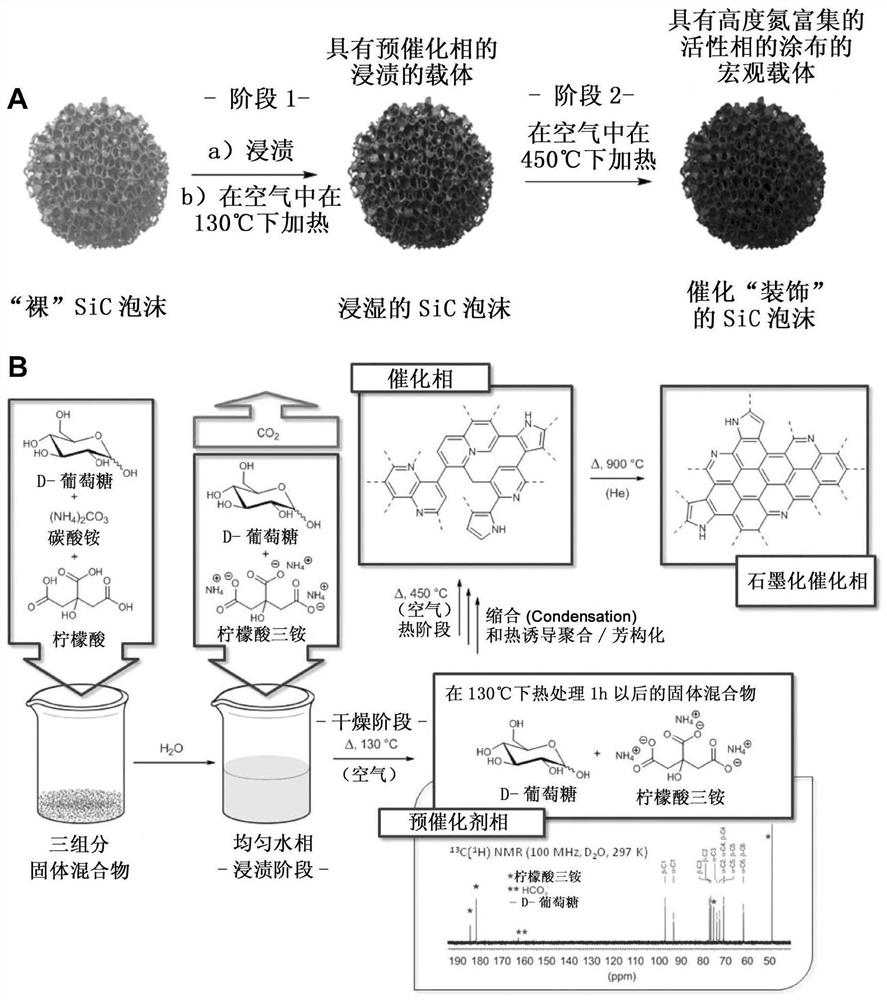

[0128]Example 1. General procedure for active phase for high N-en-enrichment.

[0129]In a typical procedure, 2 g of dextrose and 3 g citric acid were added to deionized water (10 mL) at room temperature (R. T.). Then, a fixed amount of ammonium carbonate (i.e., 1, 2 or 3 g) was added to the mixture solution at room temperature and observed due to CO2Instantaneous Effervescence released (INSTANTANEOUS Effervescence). The suspension was stirred at room temperature until a clear solution was obtained as a source mixture for obtaining an N-doped carbonaceous material deposited on a suitable vector (after soaking / impregnation) of the carrier. As for the latter, use 2G different carriers, that is, SiC extrudate (30m2 G-1; SICAT), SiC powder (25m2 G-1; SiCAT, SIC foam (30m2 G-1SiCAT, and α-al2O3Bead (6m2 G-1Sasol). Slowly heat wet solid in the air: from room temperature to 130 ° C (10 ° C min-1The heating rate is maintained at this temperature for 1 hour. The obtained dry solids were furth...

Embodiment 2

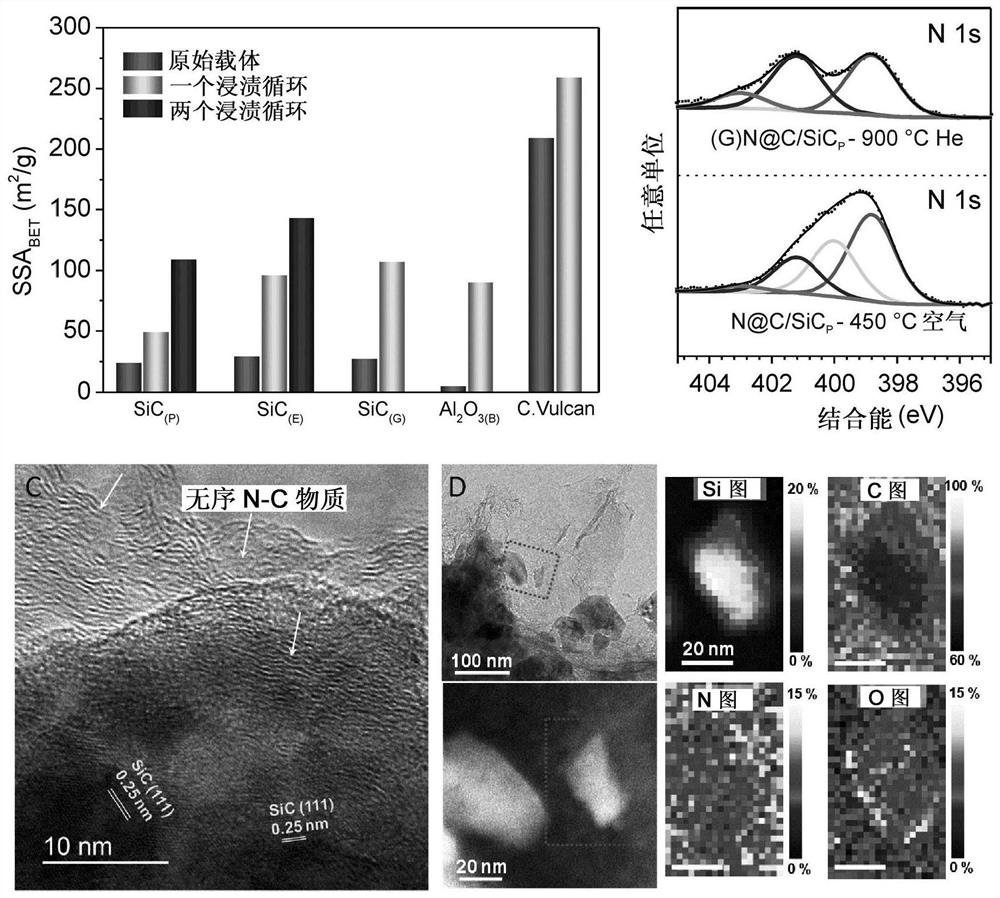

[0130]Example 2. Material Characterization.

[0131]Use the Bruker Avance DRX-400 spectrometer (400.13 and 100.61 MHz, used for1H and13C) get 1D for all samples (1H and13C {1NMR spectrum. Take PPM in units, relative to trimethylsilane (TMS), reference residual solvent resonance (1H and13C) The chemical displacement is reported to report chemical displacement (δ).

[0132]Use the setaram instrument, use 25ml · min-1Air flow rate and 10 ° C from room temperature to 1000 ° C · min-1The heating rate is used for thermal weight analysis (TGA). In the liquid nitrogen temperature, use N2As the adsorbent (Tristar Sorptometer), the specific surface area of different samples is measured. Before the measurement, the sample was degassed at 200 ° C overnight to desorb moisture and impurities on the surface thereof. The xps measurement of the carrier was used for 10 minutes of acquisition using a MultiLAB 2000 (Hν = 1486.6EV) spectrometer. Peak Deconvolution is performed with the "Avantage" program fr...

Embodiment 3

[0133]Example 3. Catalytic reaction

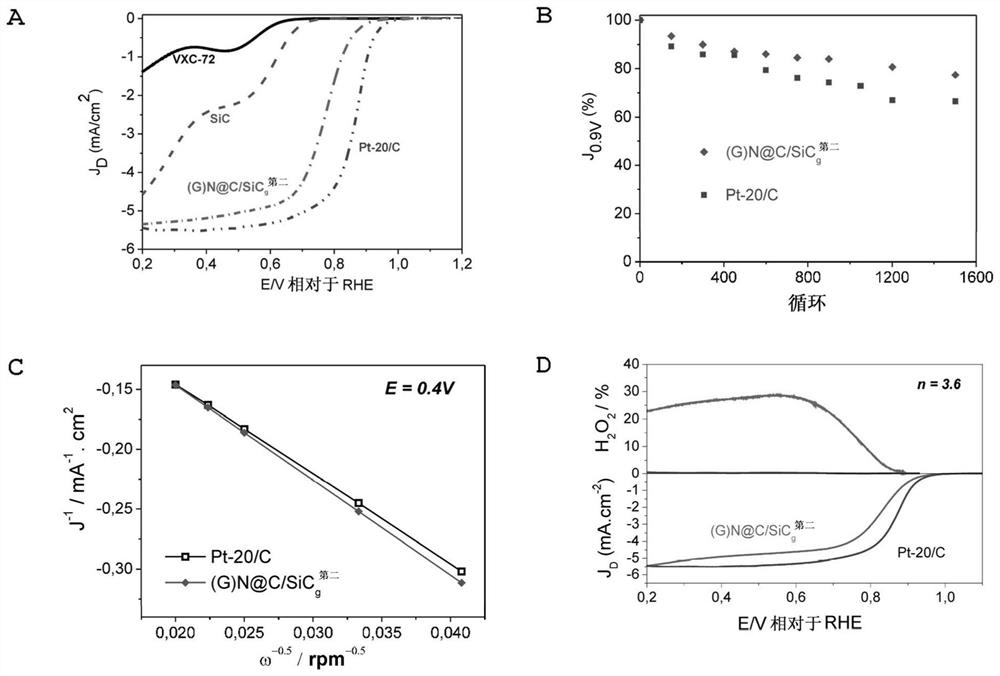

[0134]3.1 Oxygen Reduction Reaction (OR).

[0135]In the three-electrode battery, in the electrolyte in 0.1M KOH, the scanning rate is 10 mV s.-1AUTOLAB PGSTAT 30 (ECO Chemie, Netherlands) constituentator of the simulated linear scan generator, electrochemical studies at 25 ° C. The oxide (Hg / HGO) electrode and the PT wire electrode are used as the reference electrode and the counter electrode, respectively. Unless otherwise stated, all potentials are referred to as an invelectible hydrogen electrode (RHE). Electrochemical impedance spectroscopy (EIS) is used to determine the electrolyte solution resistance.

[0136]Ultrasonic waves were mixed with 10.0 mg of catalyst samples, 5 ml isopropanol, and 50 μl of Nafion solution (5 wt%) to form a homogeneous catalyst ink. For defined RRDE test, by loading 50 μl of catalyst ink to a pretreatment glass carbon (GC) electrode (5.5 mm diameter and 0.2376cm2Geometric area), then dry at room temperature to prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com