Device and method for preparing high-entropy alloy coating through electric spark deposition

A technology of electric spark deposition and high-entropy alloy, which is applied in metal material coating process, coating and other directions, can solve the problems of difficulty in taking into account efficiency and deposition quality, high porosity of thermal spraying technology, and high cost of laser cladding technology. The effect of stable EDM deposition process, improving EDM deposition efficiency, and reducing surface thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

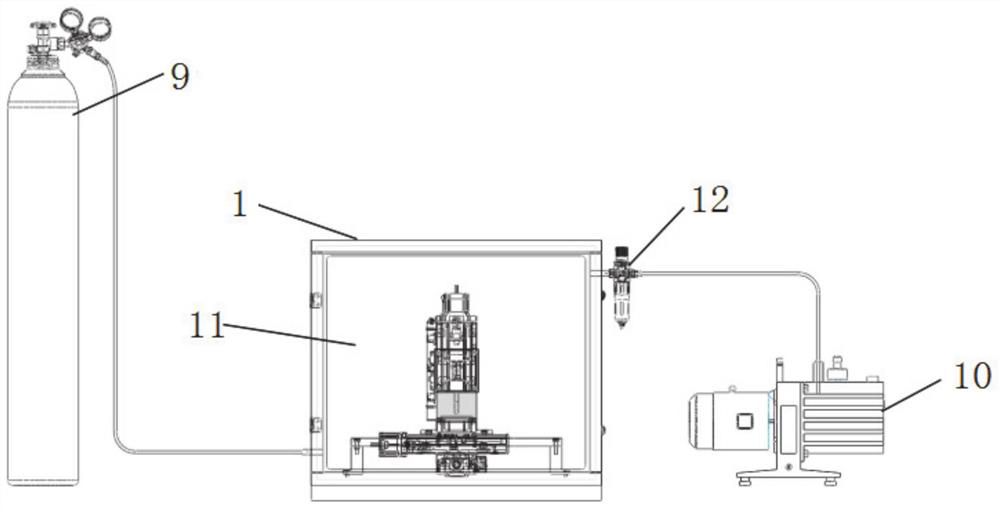

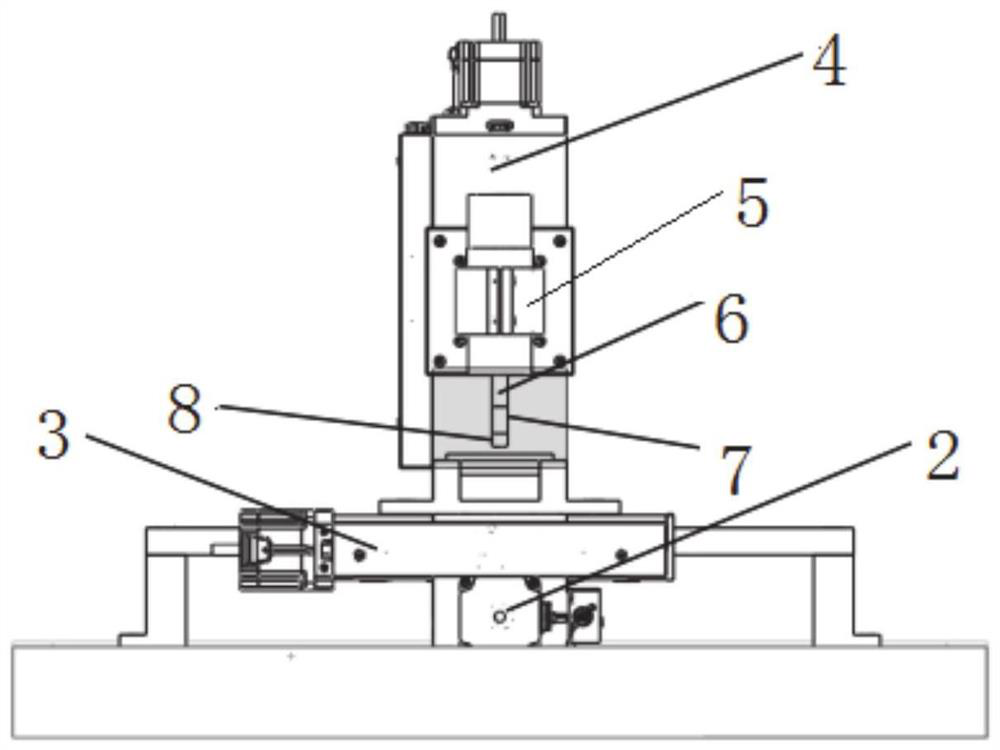

[0040] In a typical implementation of the present application, such as Figure 1-3 As shown, a device for preparing high-entropy alloy coatings by EDM, including a processing mechanism, a protective gas supply mechanism, and a power supply assembly.

[0041] The processing mechanism includes a sealing cover 1, and a two-axis linkage mechanism is fixed inside the sealing cover.

[0042] The two-axis linkage mechanism can adopt the existing two-axis linkage mechanism, including the first horizontal movement mechanism 2 , and the moving part of the first horizontal movement mechanism is connected with the second horizontal movement mechanism 3 . The second horizontal movement mechanism is vertically arranged with the first horizontal movement mechanism. The moving part of the second horizontal moving mechanism is fixed with a base 20 made of insulating material, the base is used to place workpieces, and the two-axis linkage mechanism can output two mutually perpendicular movemen...

Embodiment 2

[0061] This embodiment discloses a working method of the device for preparing a high-entropy alloy coating by electrospark deposition described in Embodiment 1, comprising the following steps:

[0062] Step 1: In the sealed cover, use the protective gas supply mechanism to fill the protective gas, immerse the workpiece to be processed in the protective gas and place it on the insulating base, install the tool electrode and the piezoelectric actuator on the machine tool spindle, and connect the workpiece with the Connect the negative pole of the power supply assembly, connect the tool electrode to the positive pole of the power supply assembly, open the gas cylinder, pressure regulating valve, and rotary vane vacuum pump to complete the preparation for processing.

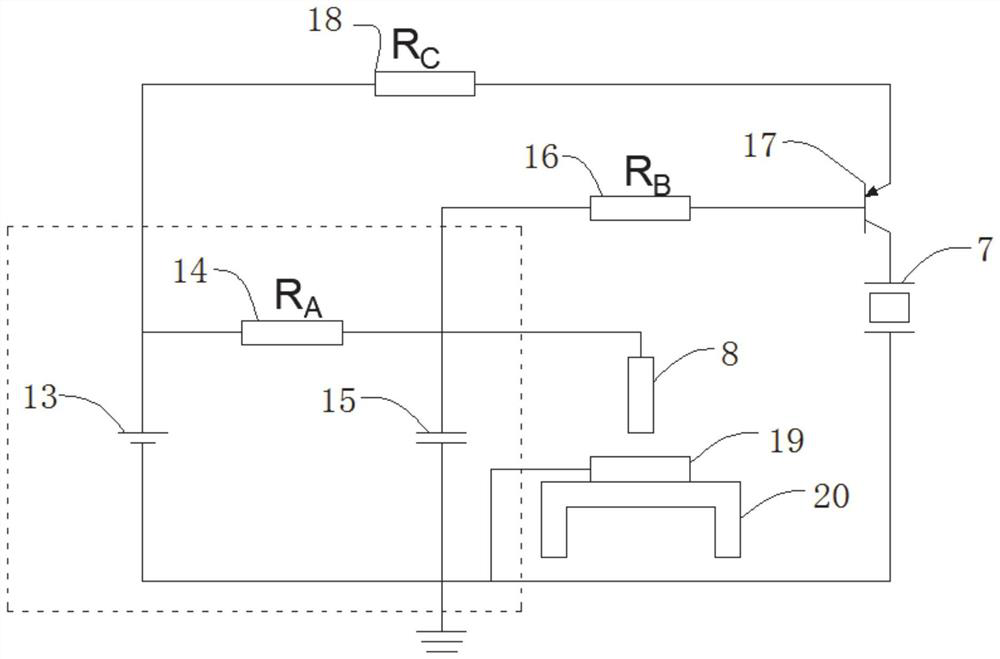

[0063] Step 2: Start the power system and power supply components of the machine tool spindle. The power supply components apply pulses between the tool electrodes and the workpiece, and use the charging and discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com