Water-loss prevention and short-circuit prevention bag type alkali storage battery

A storage battery and anti-short circuit technology, which is applied in the direction of alkaline storage battery, production of alkaline storage battery, battery pack parts, etc. It can solve the problem that the positive plate is easy to directly contact the negative electrode through the grid holes, and has no ability to absorb and store liquid , battery life termination and other issues, to achieve excellent acid and alkali resistance, reduce the frequency of water replenishment, and the effect of small diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

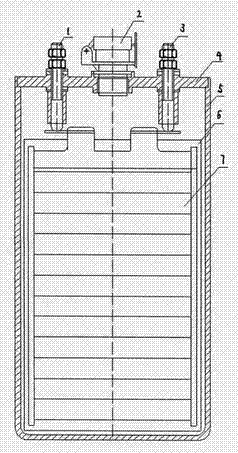

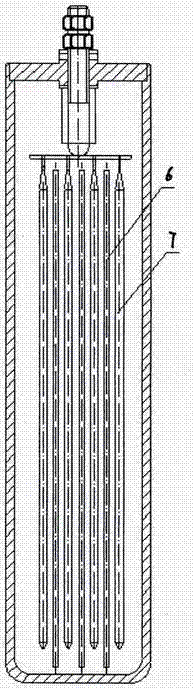

[0007] The embodiment is described in detail in conjunction with the accompanying drawings. The present invention is an improvement to the prior art. It includes a battery case 5, a pole plate 7, a battery cover 4 and its positive terminal 1, negative terminal 3, and air plug 2. The main improvements are The advantage is that a layer of polypropylene needle-punched felt 6 is installed between the bag-type positive electrode plate 7 and the bag-type negative electrode plate. Polypropylene needle-punched felt is made of polypropylene short fiber and high-strength silk to form a reinforced base fabric, which is made into polypropylene needle-punched felt with a size of 120×155×2.0 (mm) through acupuncture reinforcement, calendering, heat setting and other processes, and is breathable. The rate is 70-80L / ㎡s, and the liquid absorption rate is 68-90%. During the long-term charge and discharge process, it can reduce the water loss of the electrolyte and avoid the internal short circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com